September 28, 2023

From the 2021 UPC Illustrated Training Manual, Chapter 9, VENTS

901.2 Vents Required. Each plumbing fixture trap, except as otherwise provided in this code, shall be protected against siphonage and backpressure, and air circulation shall be ensured throughout all parts of the drainage system by means of vent pipes installed in accordance with the requirements of this chapter and as otherwise required by this code.

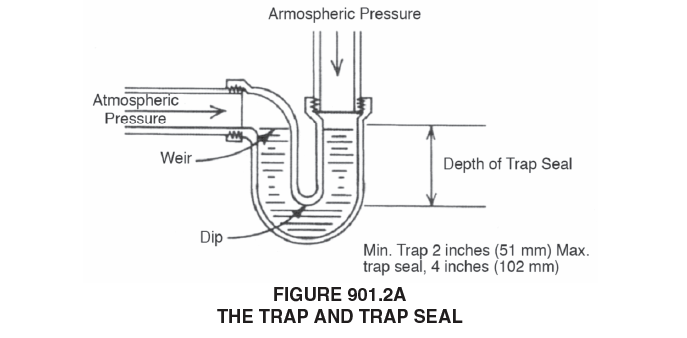

This section requires that the fixture trap be protected against siphonage and backpressure by means of a vent system. The principle of ventilating the drainage system to retain trap seals has been the basis of modern plumbing systems since the end of the 19th century. Prior to the 20th century, plumbing fixtures were rarely used inside the building. The protection of the trap and its trap seal (see Figure 901.2a) by a vent has allowed the plumbing fixture to be placed safely inside the building see also commentary for traps and trap protection in Sections 1001.2 and 1002.1). Without a vent, the trap seal is subject to siphonage or backpressure, which would allow sewer gas to enter the building or room. The consequences of sewer gas escaping the drainage system and entering the room can be lethal, as was proven in the SARS epidemic (Severe Acute Respiratory Syndrome) reported in Hong Kong, China in 2003, where 65 deaths and 321 infected people resulted from the virus being transmitted in part through dry traps.

Siphonage

Siphonage can occur in two ways. It occurs when there is sufficient negative pressure (aspiration or negative pressure below atmospheric) to draw water out of the fixture trap. A negative pressure occurs in a drainage stack as water rapidly flows downward, drawing air into itself (entrainment). If the sheet of water flows past an unvented branch connecting to the stack, a negative pressure will also be produced in the branch affecting any trap seals in the branch. If the negative pressure is great enough, then a siphon will occur. Also, a negative pressure occurs in the drain when a fixture is discharged. The discharging fixture may siphon an adjacent fixture trap that is not vented. For these reasons, venting is required to relieve any aspiration that may affect a trap seal.

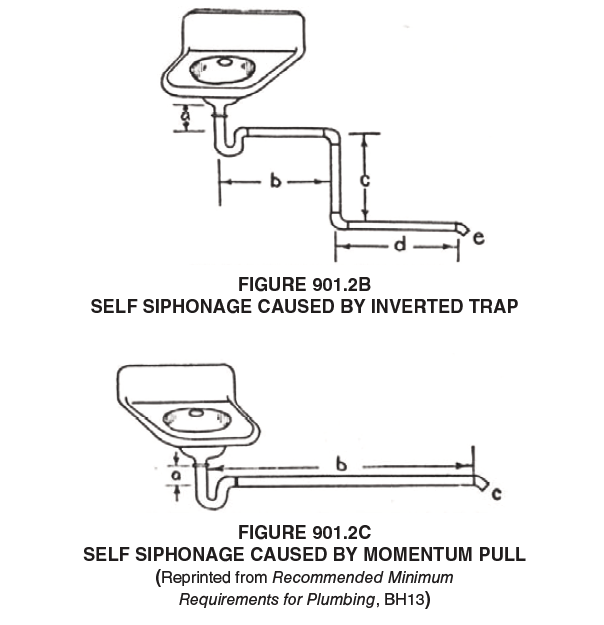

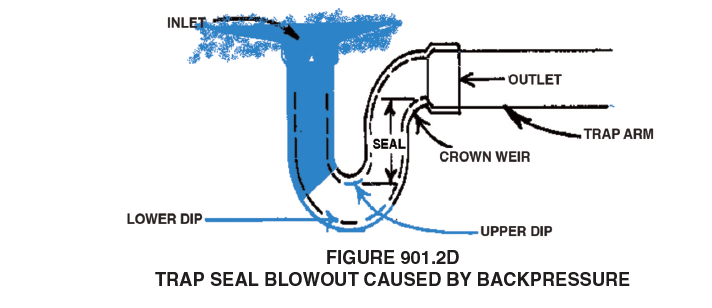

Siphonage may also occur by a fixture siphoning itself at the end of its discharge. This is called self-siphonage. According to Recommended Minimum Requirements for Plumbing (BH13) published by the National Bureau of Standards (NBS), self-siphonage occurs when there is an unbalanced water column in an inverted U shape caused by the Ptrap as seen in the common siphon (see Figure 901.2b). Selfsiphonage is also caused by the fluid velocity, or the momentum pull exerted by the moving column of water, whether the pipe is horizontal, vertical, or inclined. In a horizontal drain from the trap, the momentum pull in its full intensity is exerted at the end of the discharge (see Figure 901.2c). Therefore, such configurations are prohibited without the fixture traps properly vented to prevent selfsiphonage.

Backpressure

Backpressure occurs when there is positive air pressure (increase or positive pressure above atmospheric) in the drainage system. As water flows down a stack drawing air along with it, it also pushes air ahead of itself. The air volume will flow through the building drain and dissipate into the sewer drainage system unless there is a blockage in the air path, such as when the building drain is full, or when there is a building trap or a backwater valve. Such blockages in the air path generate positive pressures and may have an adverse effect on trap seals. This back pressure on the outlet side of the trap could push air bubbles through the trap way releasing sewer gas into the living space and, if significant enough, could even blow the water out of the trap way (see Figure 901.2d).

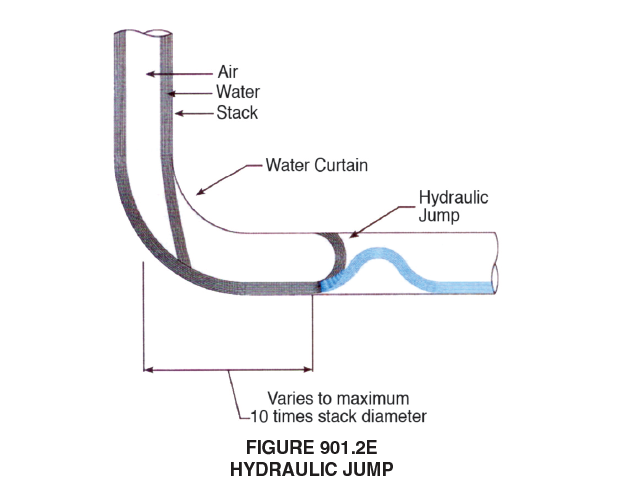

A particular blockage or closure in the air path is the hydraulic jump. A hydraulic jump is a flow condition where the flow rate becomes greater than the drain capacity causing the depth of the flow to be greater than the pipe diameter. This sudden rise is called a jump and may completely block air flow (see Figure 901.2e). Hydraulic jumps may occur at horizontal junctions where one branch flows into another and at the base of drainage stacks (see also commentary in Section 706.4). When the hydraulic jump completely fills the drain, positive air pressure waves will be generated, and if they last long enough then traps seals in close proximity may be affected. Backpressures generated by hydraulic jumps must be relieved by the venting system to protect trap seals.

Air Circulation

Section 901.2 also requires air circulation shall be ensured throughout all parts of the drainage system by means of vent pipes. This statement means that air must circulate throughout the drainage system including the building drain, building sewer, and public sewer. The basic principles of venting ensures that the equalization of atmospheric pressure on both sides of the trap seal within plus or minus one-inch water column, will be provided at all times and in all parts of the drainage system.

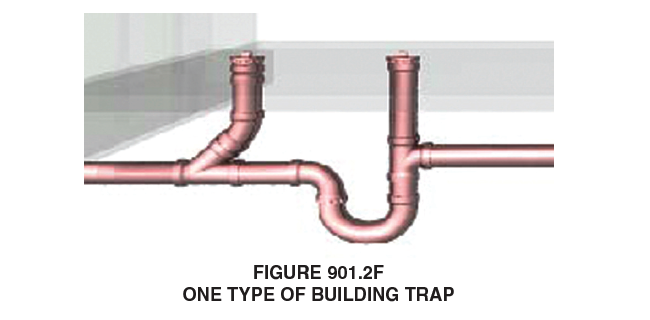

As already mentioned, building traps (see Figure 901.2f) block air circulation to the building drain and sewer and therefore are prohibited in Section 1008.1 except where allowed by the Authority Having Jurisdiction (AHJ). The reason the building trap is not used extensively in the Uniform Plumbing Code (UPC) is that the storm system is intended to be separate from the sewer system. Sewer manholes are sealed unlike storm system manholes and do not provide for air circulation in the sewer system. Therefore, the circulation of air for the public sewer, the building sewer and the building drainage system must come from the vents in the building alone. In Section 1008.1, the building trap is allowed but will require a relieving vent to provide for the circulation of air upstream of the buildingtrap, and in Section 904.1 it will require another vent downstream of the building trap to allow circulation of air to the public sewer or private sewage disposal system.

The 2021 Uniform Plumbing Code Illustrated Training Manual is available for purchase here.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: September 28, 2023