CIRCUIT VENTING AND THE UNIFORM PLUMBING CODE

Presented by Des Moines, Iowa, plumbing inspector and IAPMO Board of Directors member Brian Hamner, the Uniform Plumbing Code® (UPC) seminar at IAPMO’s 93rd annual Education and Business Conference discussed provisions of the UPC pertaining to circuit-venting.

An Iowa native, Hamner has 25 years of experience in the plumbing trade. He began his career as a sprinkler fitter with a small company for several years before switching to plumbing. Following stints with Cook Plumbing Corp. and Golden Rule Plumbing and Heating, he moved into his current position with the city of Des Moines in 2007.

This article will provide a brief recap of his seminar.

Hamner began with a disclaimer: The information herein is provided for educational purposes only and shall not be treated as an official interpretation of the referenced codes or standards. Always refer to the complete code or standard when installing, replacing or repairing any plumbing or mechanical system.

“So, if I say something here that you think is wrong, don’t take it as the final word,” he said.

Hamner explained the first reference to the concept of circuit venting in the UPC occurred in Appendix H of the 1973-75 edition as battery drainage systems. Then 27 years later, in the 2000-06 UPC it was referenced as battery venting. In 2006, circuit venting was added.

“But guess what?” he said. “It had to be a design professional in order to put it in.”

In 2015, circuit-venting was added to the body of the code with two significant changes; the requirement for a design engineer and the word “maximum” was removed from the slope. The code language then remained unchanged until 2021, when it was overhauled considerably. Hamner’s presentation addressed many of these changes.

He began with some related definitions.

202.0 Definition of Terms.

202.1 General. The definitions of terms are arranged alphabetically according to the first word of the term.

Battery of Fixtures. A group of two or more similar, adjacent fixtures that discharge into a common horizontal waste or soil branch.

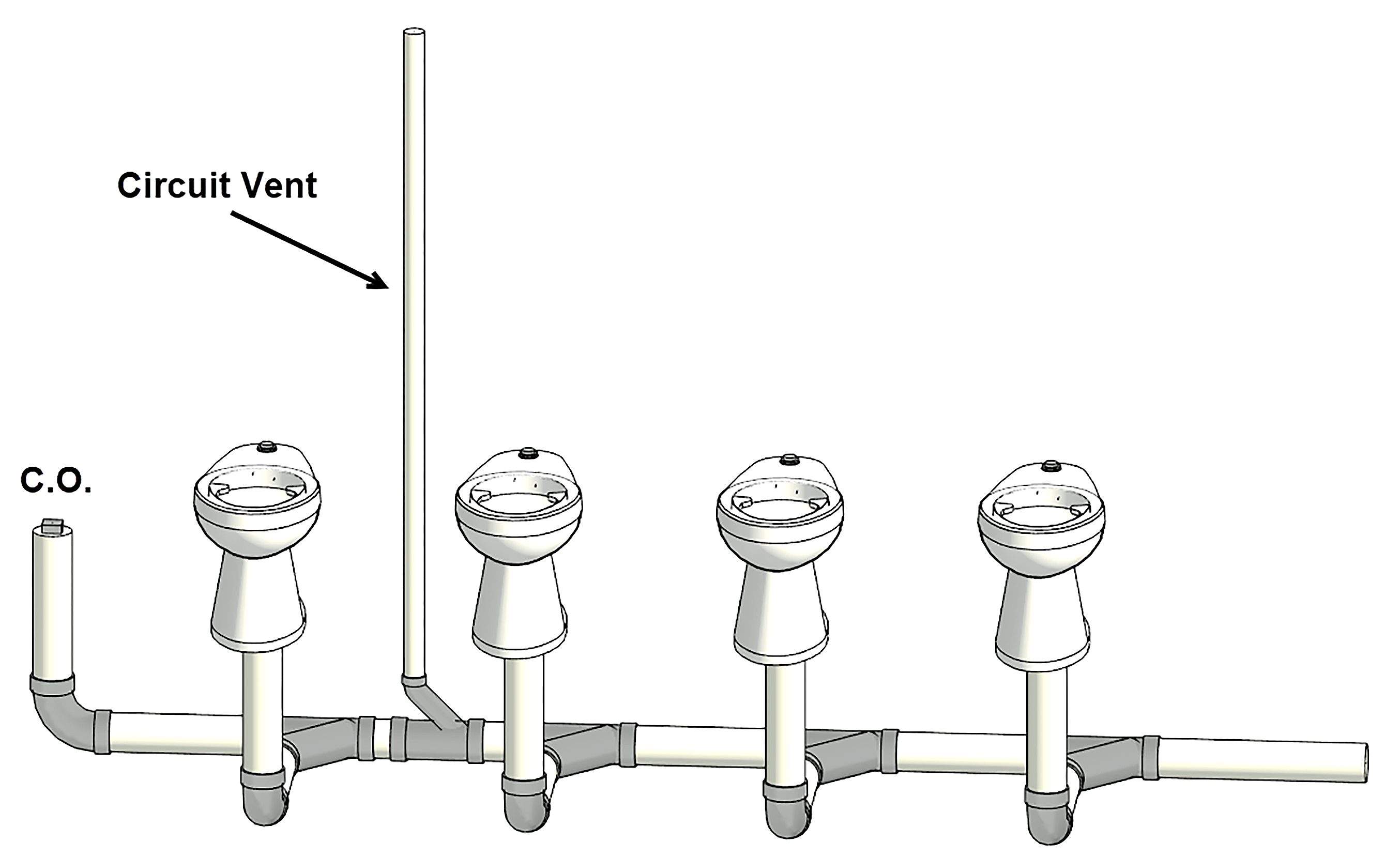

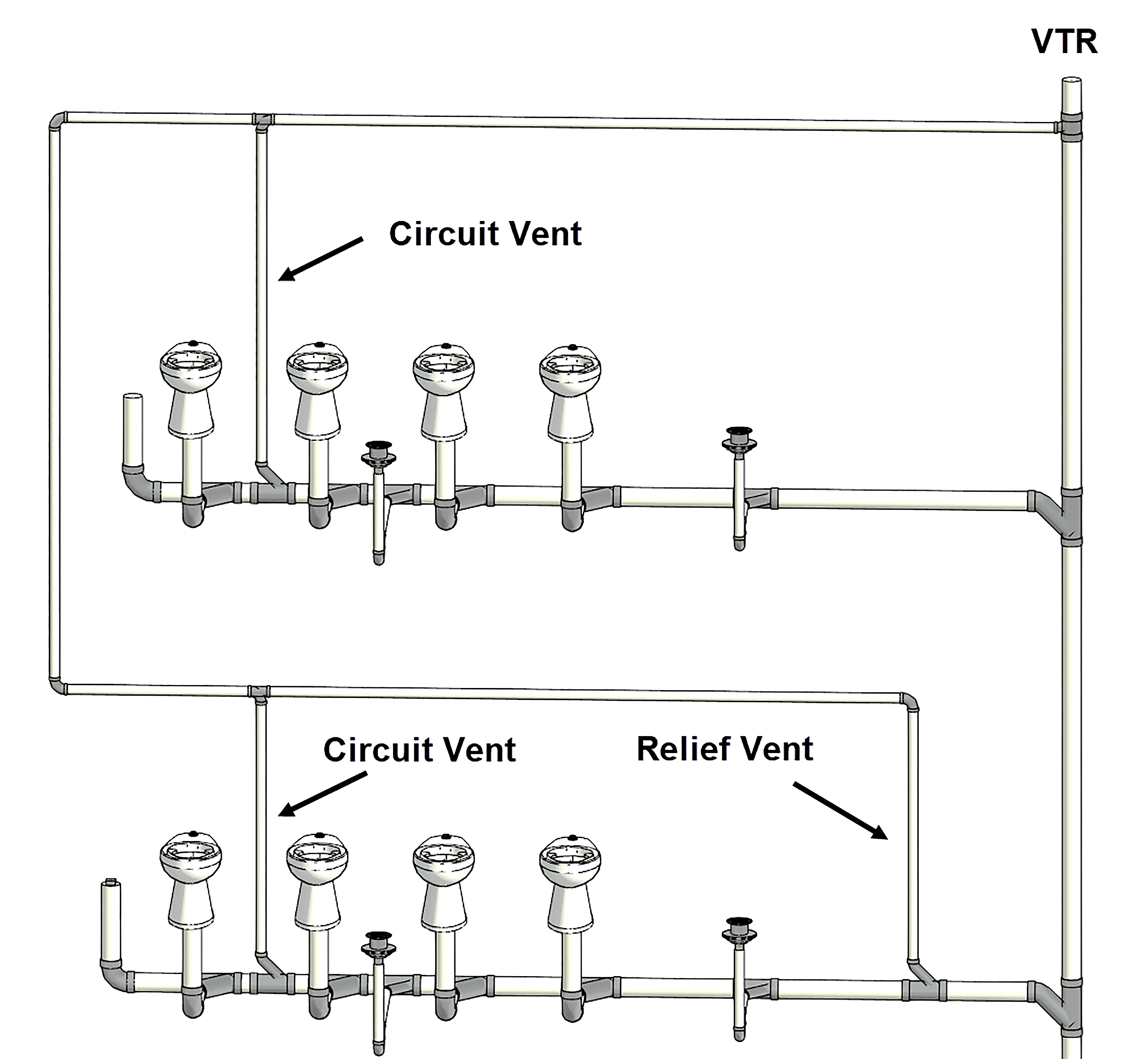

Circuit Vent. The vent that connects to a horizontal drainage branch and vents two traps to a maximum of eight traps connected into a battery of fixtures.

Dry Vent. A vent that does not receive the discharge of any sewage or waste.

Horizontal Branch. A drain pipe extending laterally from soil or waste stack or building drain with or without vertical sections or branches, which receives the discharge from one or more fixture drains and conducts it to the soil or waste stack or the building drain.

Main Vent. The principal artery of the venting system to which vent branches may be connected.

Plumbing Vent. A pipe provided to ventilate a plumbing system, to prevent trap siphonage and backpressure, or to equalize the air pressure within the drainage system.

Wet Vent. A vent that also serves as a drain.

“And we’ve got two different styles,” Hamner said. “Vertical and horizontal.”

Relief Vent. A vent, the primary function of which is to provide circulation of air between drainage and vent systems or to act as an auxiliary vent on a specially designed system.

“Back in the day with battery venting, they used the phrase ‘loop vent,’ ” Hamner said. “The loop vent and the relief vent are basically the same thing in the UPC. The relief vent is just helping relieve the pressure so if any drainage comes down from above it’s not providing any siphoning effects on the fixtures.”

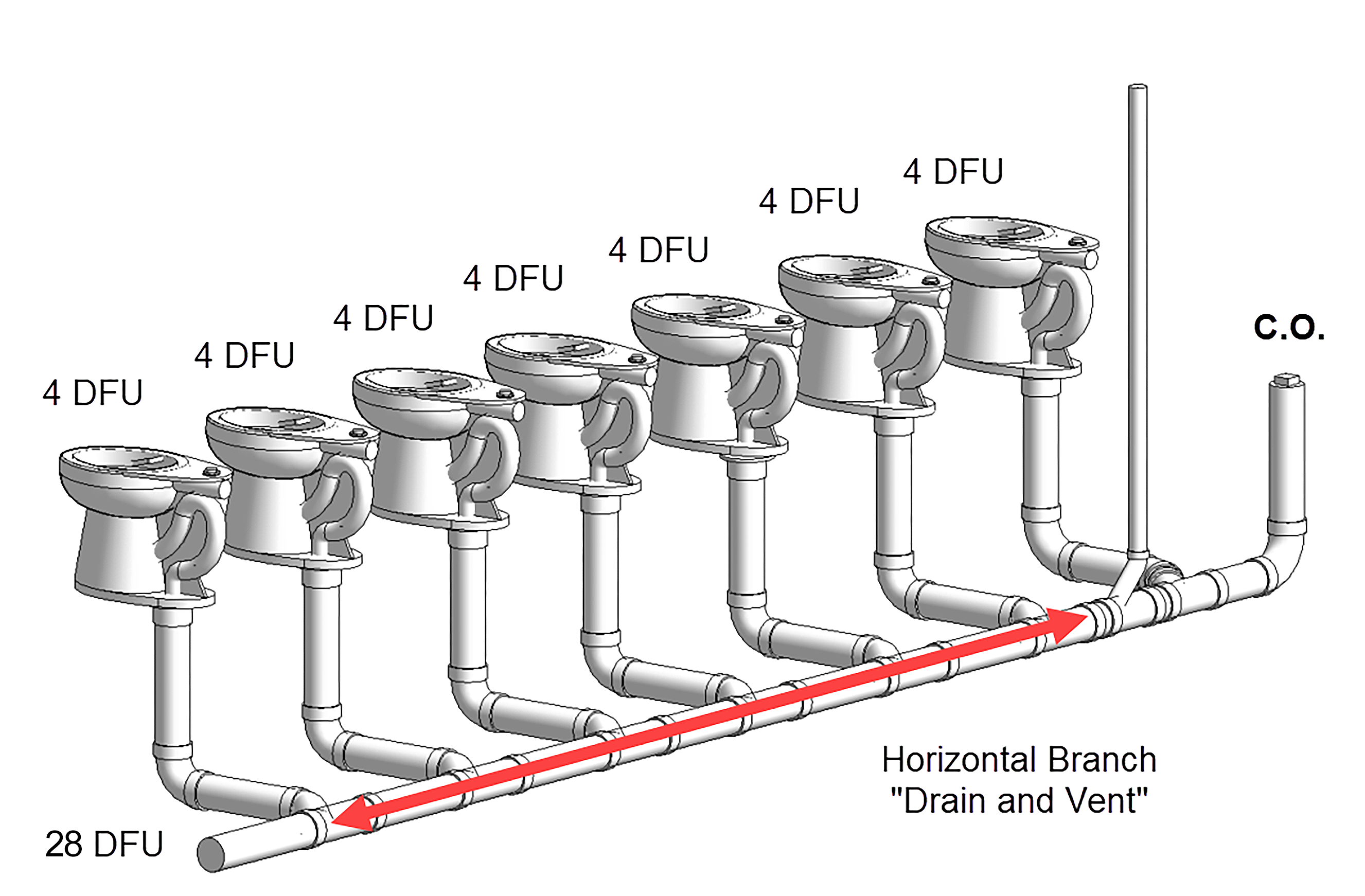

911.1 Circuit Vent Permitted. Each trap arm shall connect horizontally to the horizontal branch being circuit-vented in accordance with Table 1002.2.

911.1 Circuit Vent Permitted. The horizontal branch shall be classified as a drain and a vent from the most downstream trap arm connection to the most upstream trap arm connection to the horizontal branch.

Exception: Back-outlet and wall-hung water closets shall be permitted to be circuit- vented provided that no floor-outlet fixtures are connected to the same horizontal branch.

Trap Arm. Those portions of a fixture drain between a trap and the vent.

From there, Hamner moved into a section-by-section review of the UPC provisions for circuit venting.

911.0 Circuit Venting.

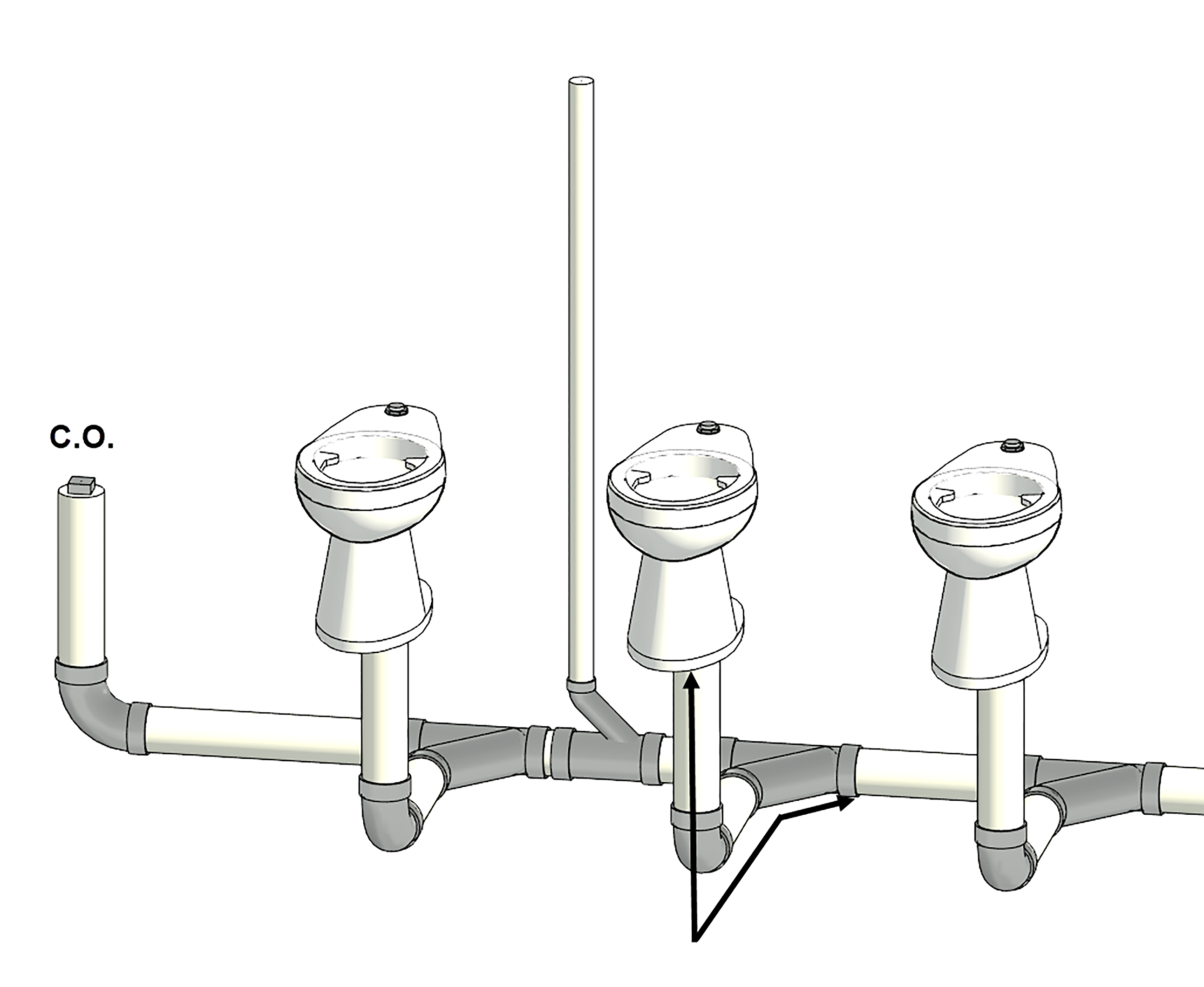

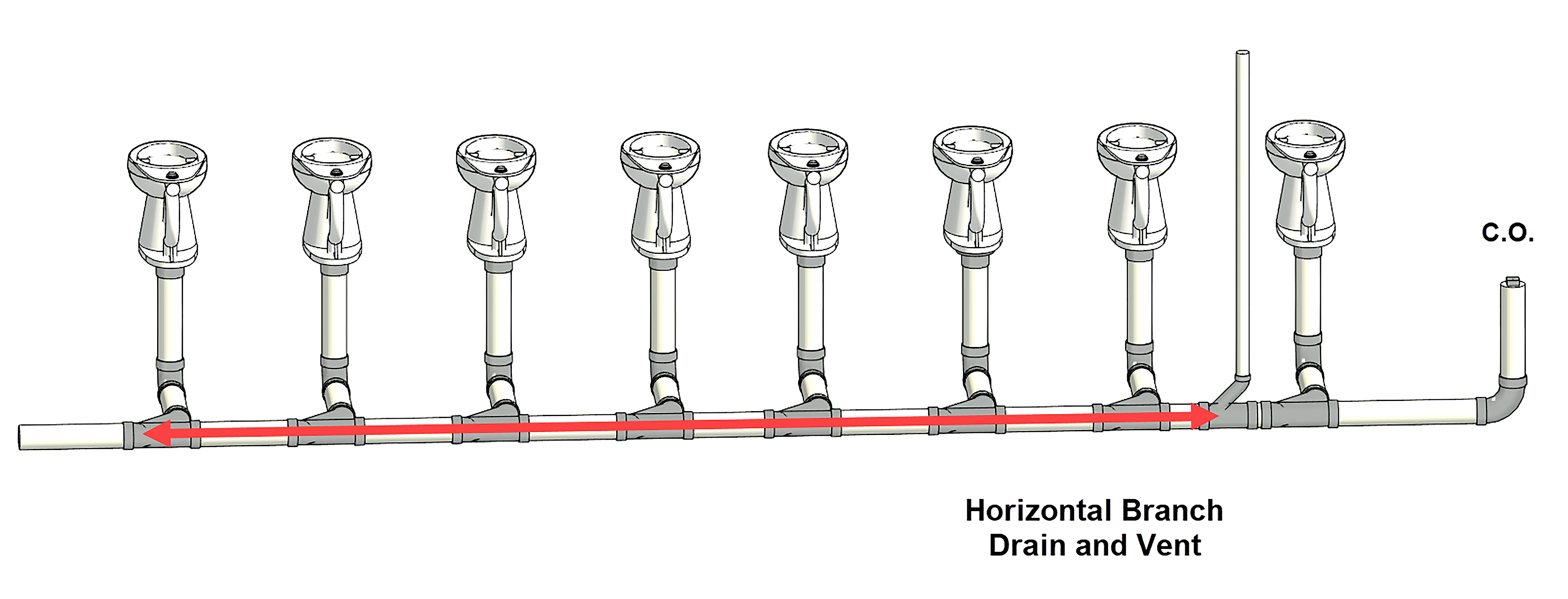

911.1 Circuit Vent Permitted. A maximum of eight floor-outlet water closets, showers, bathtubs, or floor drains connected to a horizontal branch shall be permitted to be circuit-vented. Each trap arm shall connect horizontally to the horizontal branch being circuit vented in accordance with Table 1002.2. The horizontal branch shall be classified as a drain and a vent from the most downstream trap arm connection to the most upstream trap arm connection to the horizontal branch.

“If we go back to the 2000 UPC appendices, what did it read?” Hamner asked. “Water closets, showers, bathtubs, floor drains, right? So, those are the fixtures we can drain into the horizontal part of this system. We can pick any of those and a maximum of eight on one circuit vent.”

Exception: Back-outlet and wall-hung water closets shall be permitted to be circuit-vented provided that no floor-outlet fixtures are connected to the same horizontal branch.

“Obviously we’re above the floor, right?” Hamner asked. “So, we’re not going to be able to put anything on that that’s below the floor, unless our water seal is sufficient. That’d be a heckuva water seal, though.”

911.2 Circuit Vent Size and Connection. The circuit vent size shall be in accordance with Table 703.2 according to the number of circuit-vented fixtures connected to the horizontal branch but shall be not less than 2 inches (50 mm) in diameter.

“We’ve got to figure out which fixtures are going into it, determine if it’s an assembly, public, private, add up those fixture counts, and we have to make sure our vent is sized for those fixtures loading into that horizontal branch,” Hamner said. “But no less than inches.”

The vent shall connect to the horizontal branch on the vertical between the two most upstream trap arms. The circuit vent pipe shall not receive the discharge of soil or waste.

“When this section was changed for the 2021 UPC, the words ‘trap arms’ replaced ‘fixture drain,’ ” Hamner said. “People were getting confused. We all know it’s not a fixture drain, it’s a trap arm, right?”

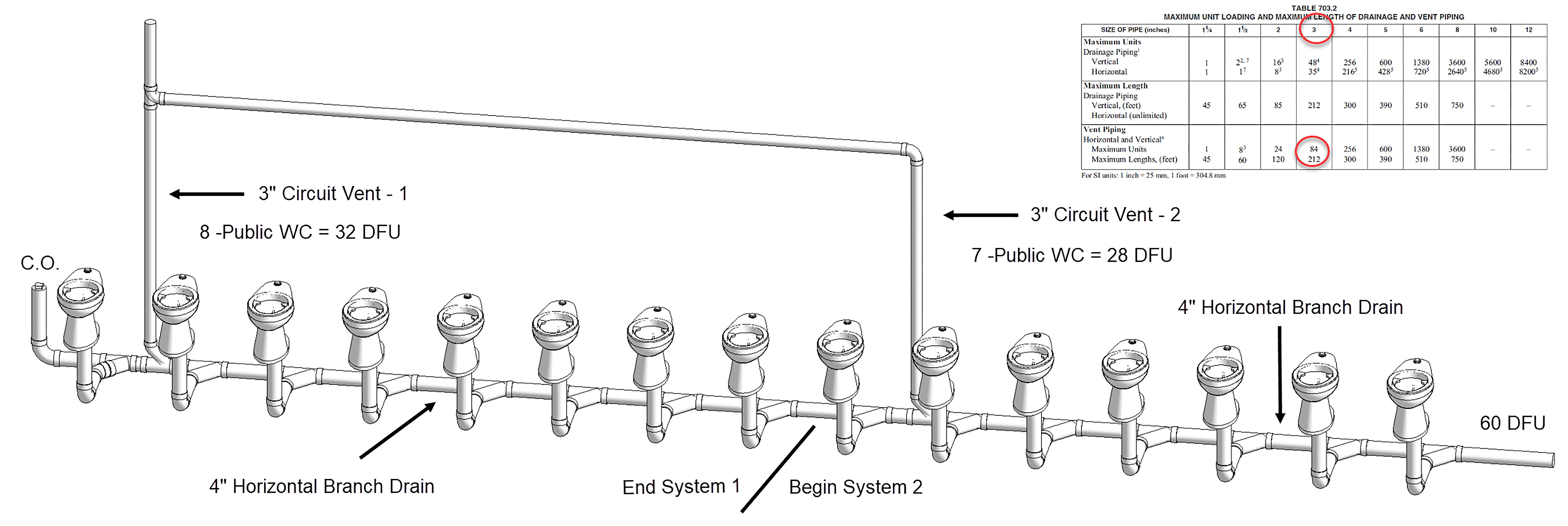

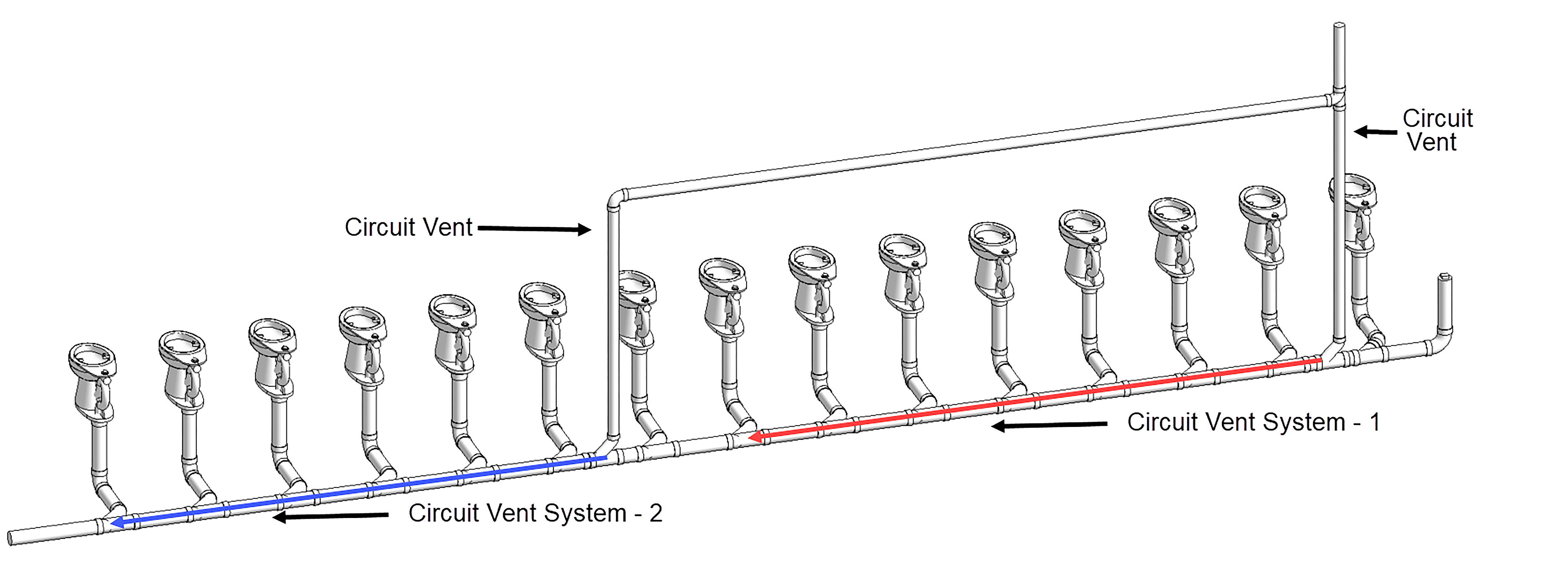

911.2.1 Multiple Circuit Vents. When multiple circuit vents are interconnected according to Section 911.4.1, each individual circuit vent shall be sized according to Section 911.2. The vent pipe connecting each circuit vent shall be sized according to Table 703.2.

“So, what this is saying is for these first eight fixtures, we have to size that circuit vent for the load of those first eight,” Hamner said, “and then there’s another section of seven here we need to now figure this vent for the load of the next section of fixtures on that circuit vent system.”

911.2 Circuit Vent Size and Connection. The circuit vent pipe shall not receive the discharge of soil or waste.

Dry Vent. A vent that does not receive the discharge of any sewage or waste.

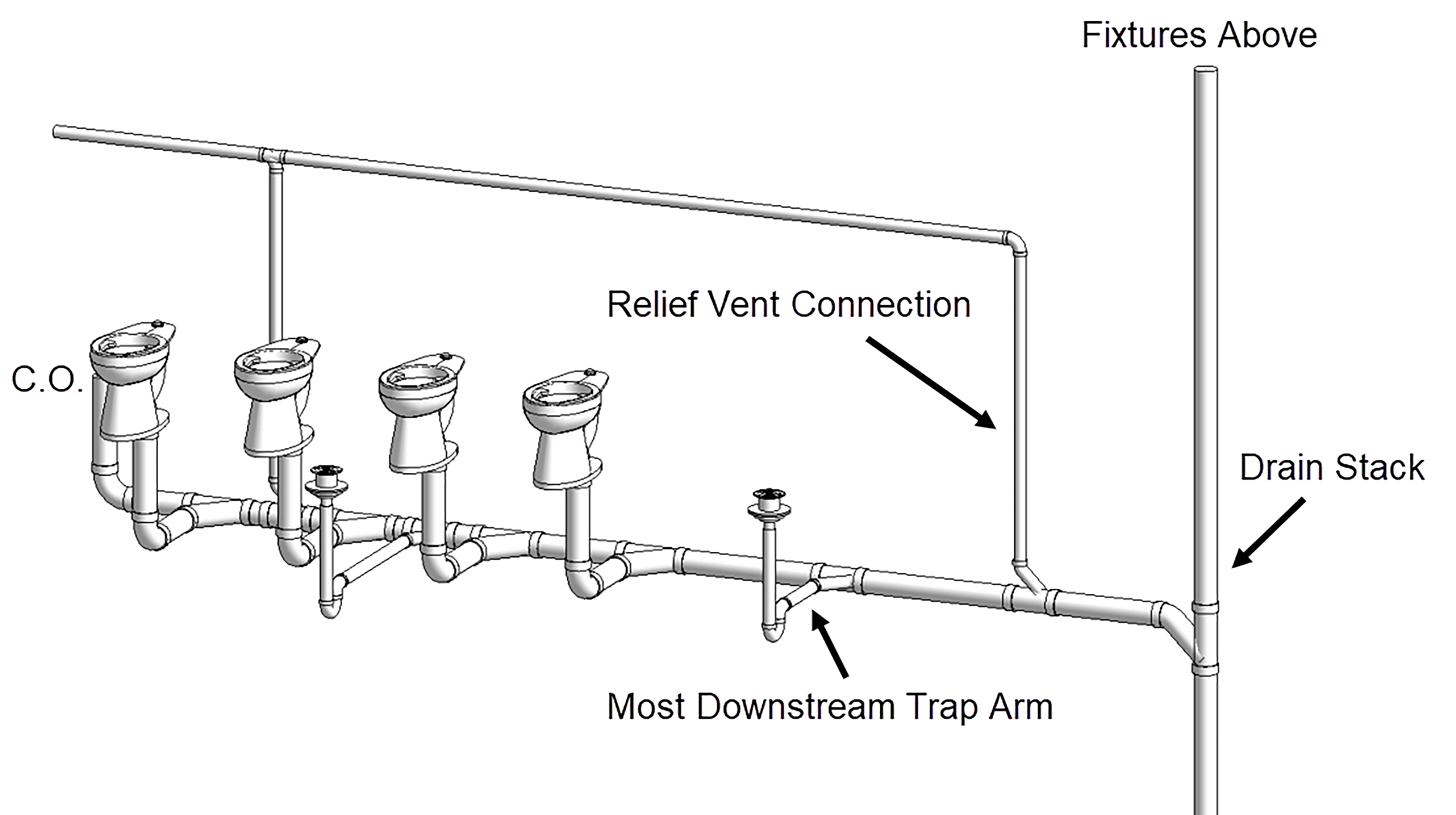

911.3 Relief Vent. A 2-inch (50 mm) relief vent shall be provided for circuit-vented horizontal branches receiving the discharge of four or more water closets when connecting to a drainage stack that receives the discharge of soil or waste from upper horizontal branches.

911.3 Relief Vent. A 2-inch (50 mm) relief vent shall be provided for circuit-vented horizontal branches receiving the discharge of four or more water closets when connecting to a drainage stack that receives the discharge of soil or waste from upper horizontal branches.

“See that little word ‘when’?” Hamner asked. “It used to say ‘and.’ So, if you have any soil dumping down a circuit vent that has four or more water closets you have to provide the relief vent. Only when you have fixtures dumping down.”

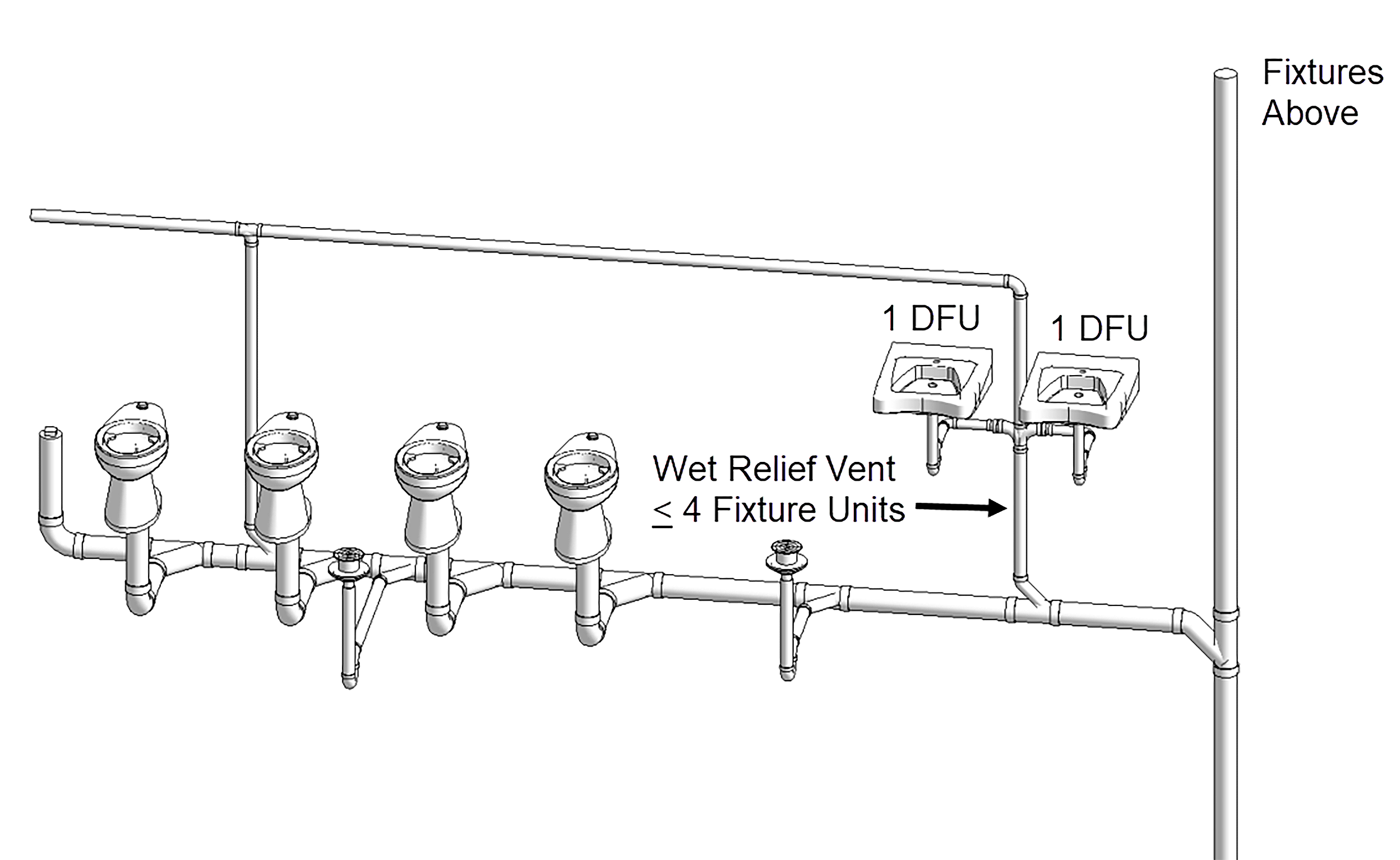

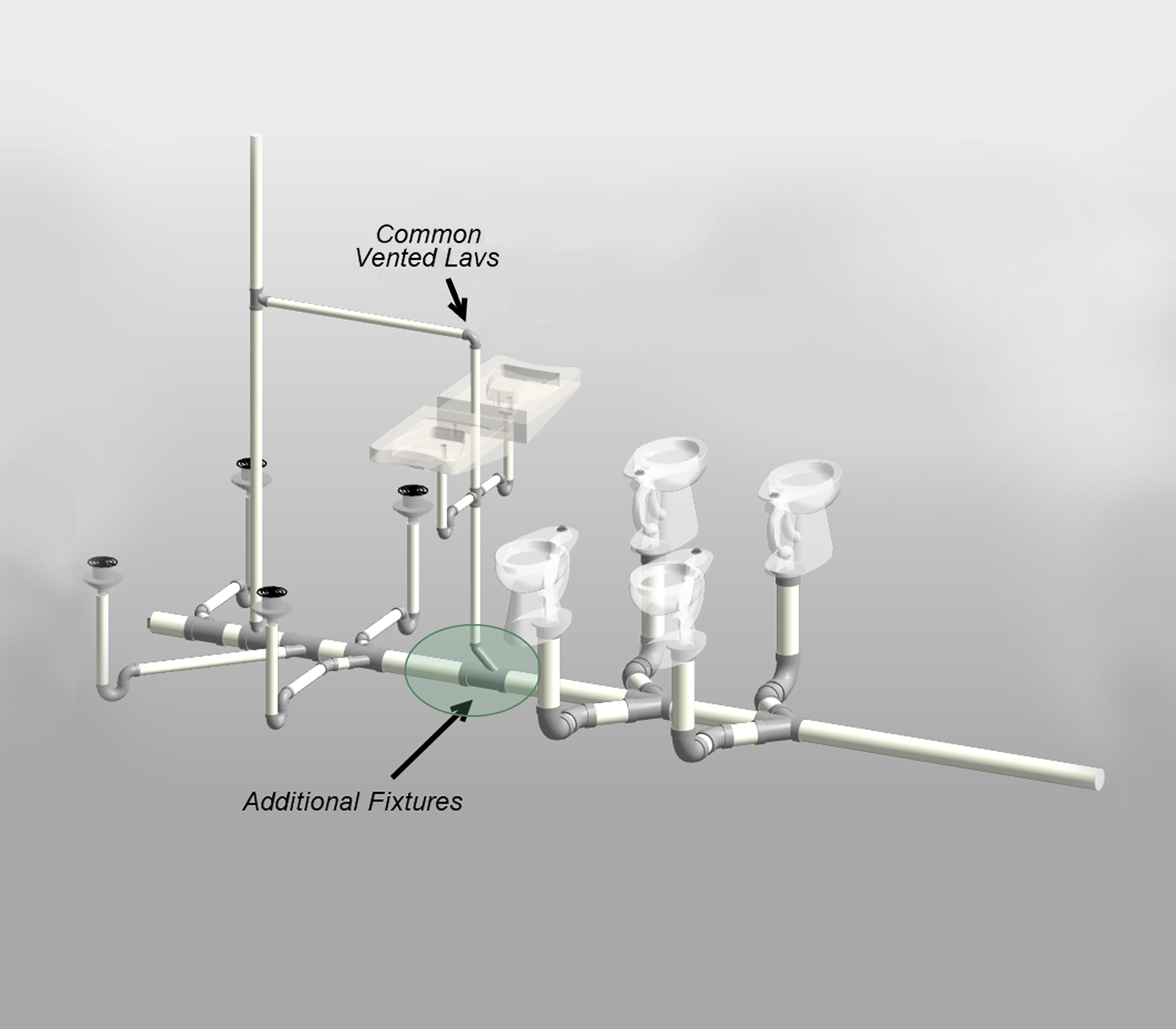

911.3.2 Fixture Drain. The relief vent is permitted to serve as a fixture drain. Fixtures discharging to a relief vent shall be one or two fixture unit fixtures but shall not exceed a total of 4 fixture units.

Hamner then said, “If I were to turn this T and start coming across, and I have eight lavatories and a circuit vent in between the first two upstream lavatories, can I do that? We can add a fixture continuously vented into the circuit vent. We can use it as a relief vent also. But we have to stick with fixtures that are one one- and two-fixture unit ratings, such as lavatories and urinals. And we can’t exceed four fixture units into that drain.”

911.3.2 Fixture Drain. The relief vent is permitted to serve as a fixture drain. Fixtures discharging to a relief vent shall be one or two fixture unit fixtures but shall not exceed a total of 4 fixture units.

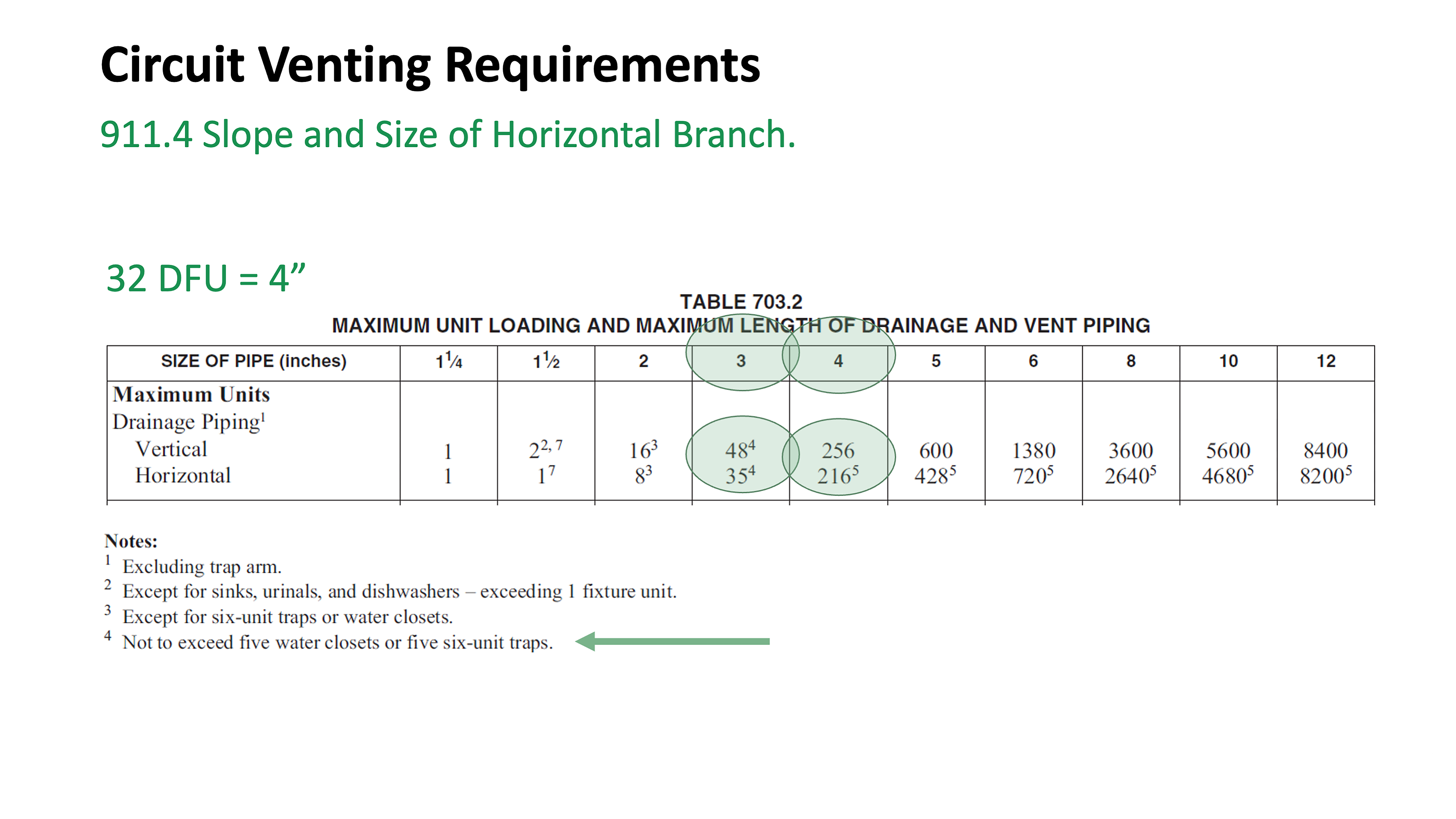

911.4 Slope and Size of Horizontal Branch. The vented section of the horizontal branch shall be uniformly sloped and not more than 1 inch per foot (83.3 mm/m). The entire length of the vented section of the horizontal branch shall be sized for the total drainage discharge to the branch according to Table 703.2.

“This is another change from the 2000 appendices,” Hamner said. “In the 2000 appendices it said 3/8-foot per inch.” Pointing to a diagram of Section 911.4 and Table 703.2, Hamner said, “In this section of pipe, since we have 32 fixture units on it, Table 703.2 says we can only do 35 and we can only have five water closets on it, that horizontal section has to go up to four-inch for its entirety, all the way from the first fixture trap arm connection.”

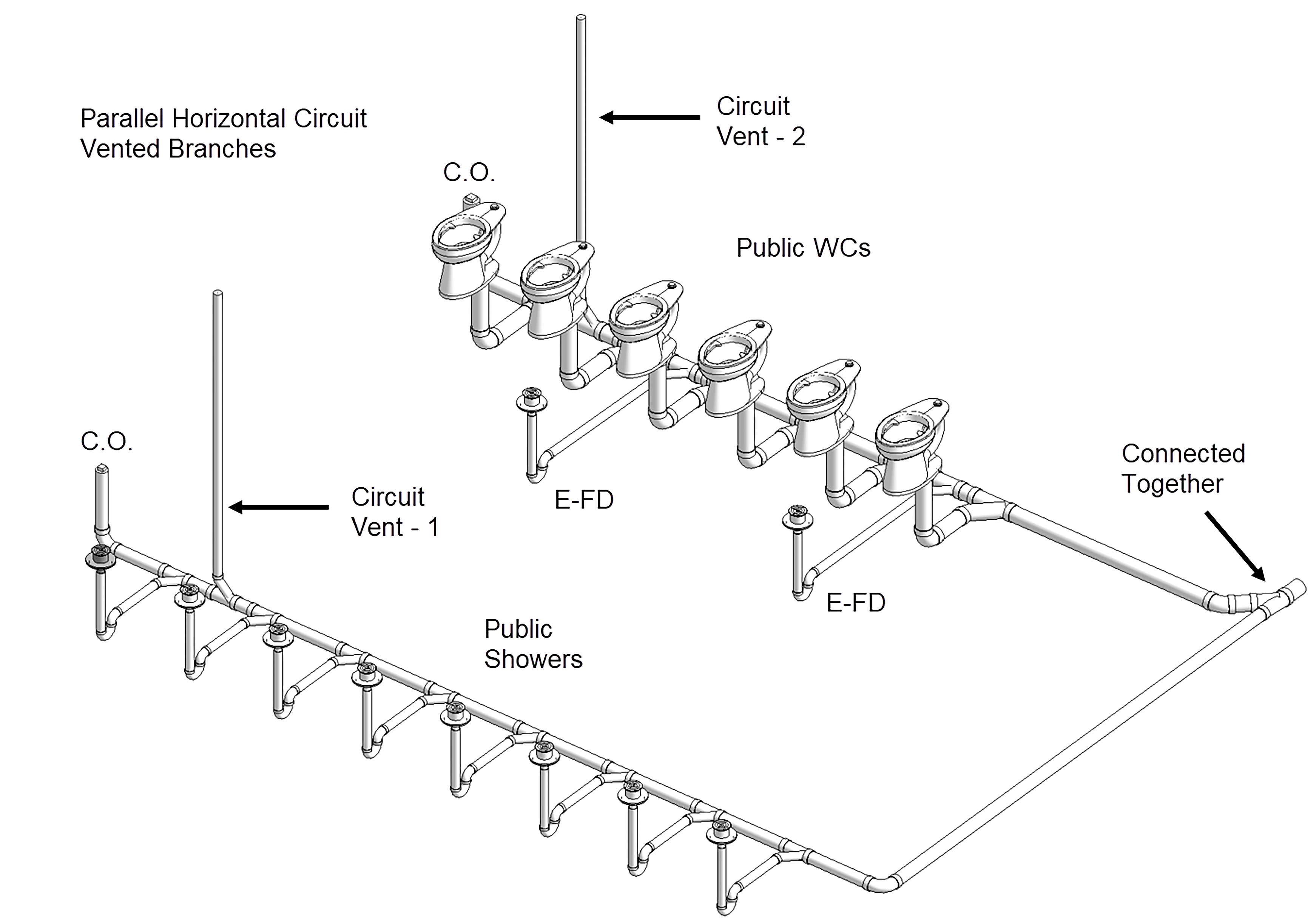

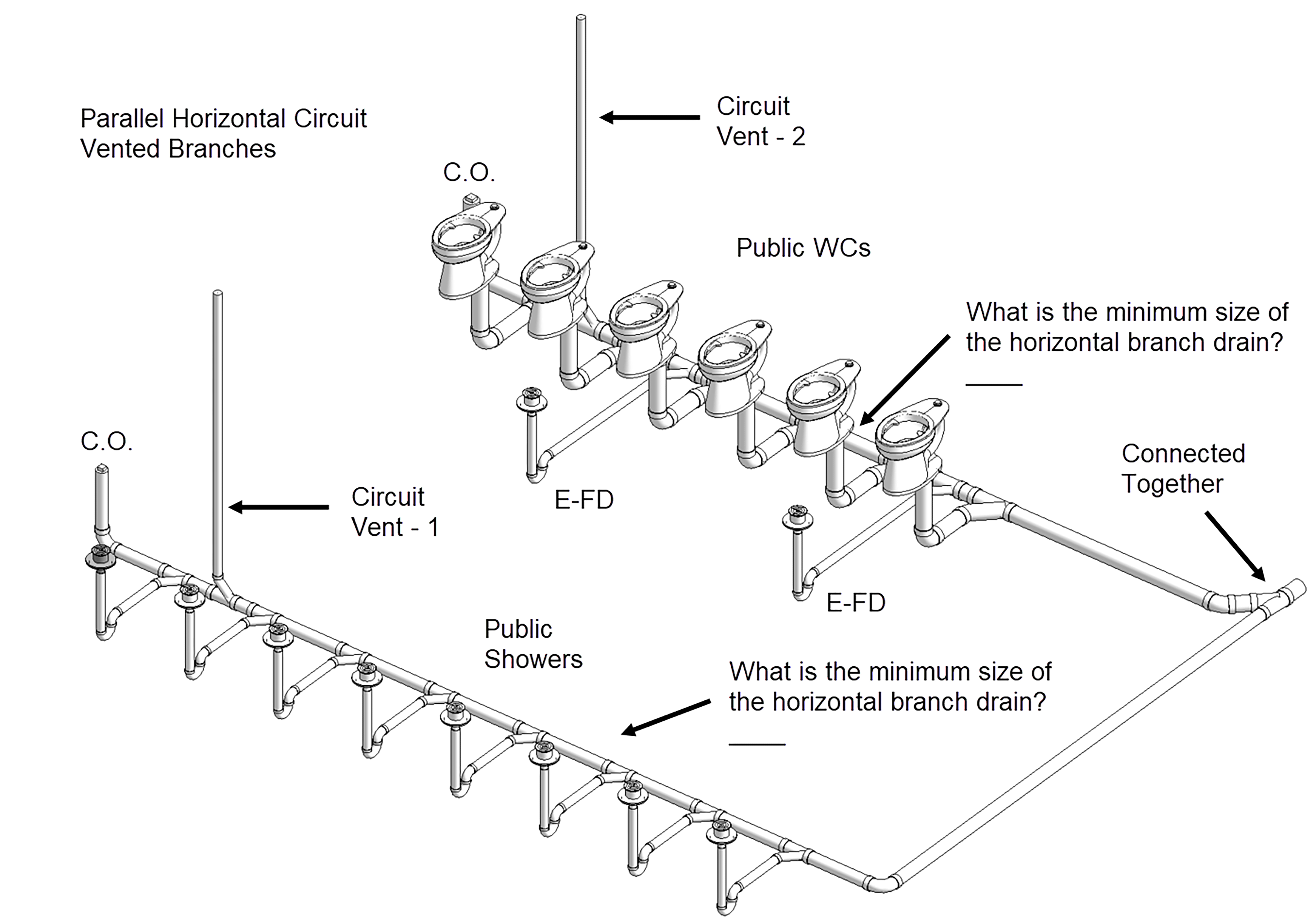

911.4.1 Multiple Circuit-Vented Branches. Circuit-vented horizontal branches are permitted to be connected together. Each group of a maximum of eight fixtures shall be considered a separate circuit vent and shall be in accordance with Section 911.4.1.1 and Section 911.4.1.2.

“We’ve still got to size it and each one has to be sized for their loading,” Hamner said.

911.4.1.1 Size of Parallel Horizontal Branches. Parallel horizontal circuit-vented branches shall be permitted to connect on the same floor level. Each separate circuit-vented horizontal branch that is interconnected shall be sized independently in accordance with Section 911.4.

911.4.1.2 Size of Continuous Horizontal Branches. Two or more circuit-vented systems continuous on the same horizontal branch shall be uniformly sized for the total discharge into the branch.

Hamner continued, “So, now we have 16, we’re going to count all those numbers up and we’re going to size that horizontal branch for all 16 fixtures and fixture units into that horizontal.”

911.5 Additional Fixtures. Fixtures, other than the circuit-vented fixtures, are permitted to discharge to the horizontal branch drain. Such fixtures shall be located on the same floor as the circuit-vented fixtures and shall be either individually or common vented.

“In 2015 when this went into the body of the code, all hell broke loose,” Hamner said. “People were doing funky stuff. That’s why it changed and changed and changed. So, the Board of Directors put an ad hoc committee together. We tried to fix it in language without changing how it functions. We couldn’t change how it functions, we could only change language because it was so confusing people were trying to do whole houses with one circuit vent.”

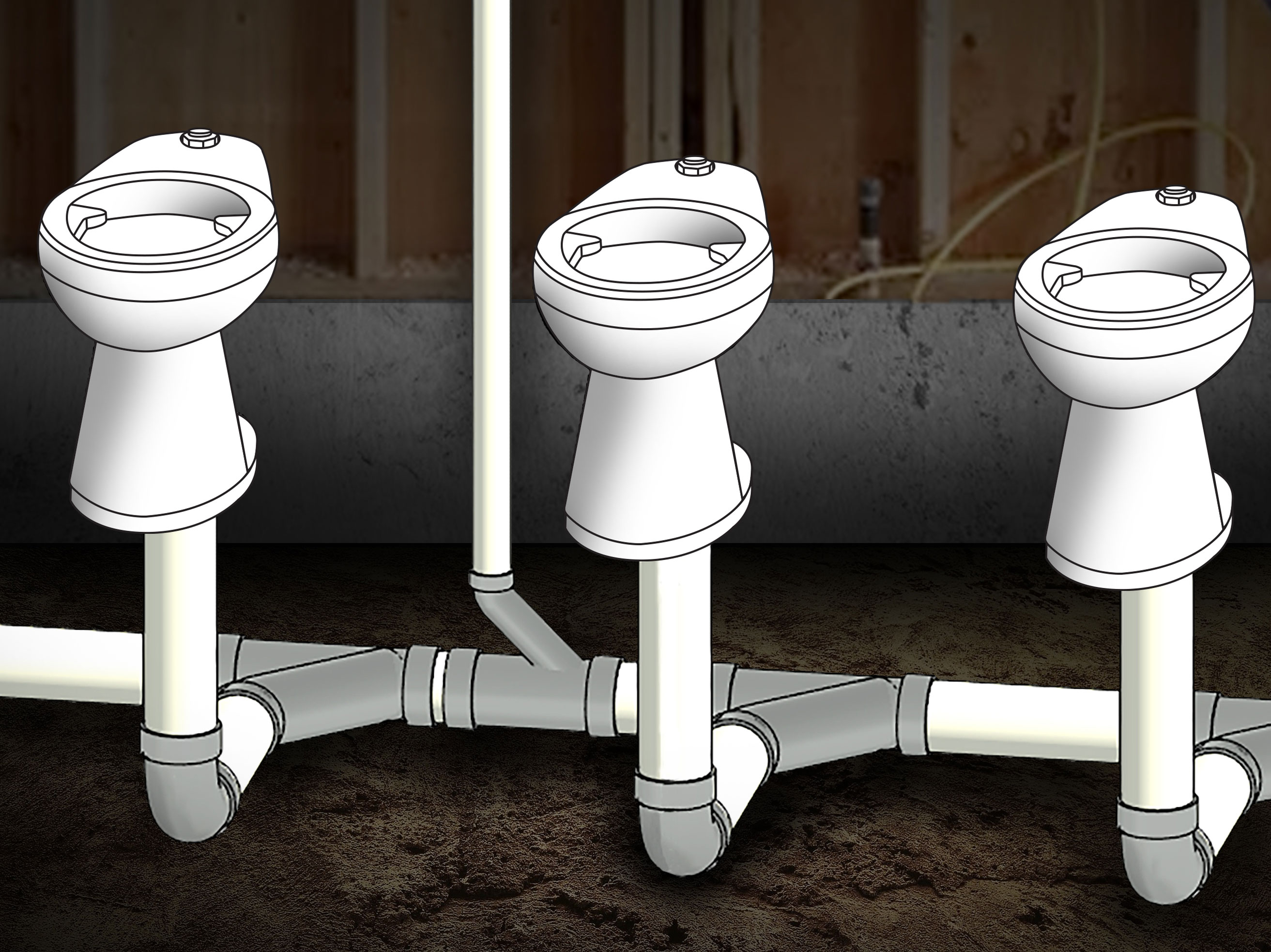

At that point, Hamner showed a series of photos representing a double wye setup in a horizontal slope and the group discussed its compliance with the UPC. To conclude the presentation, Hamner showed a series of images of other code-compliant applications and the various ways to construct them.

911.4.1.2 Size of Continuous Horizontal Branches. Two or more circuit-vented systems continuous on the same horizontal branch shall be uniformly sized for the total discharge into the branch.

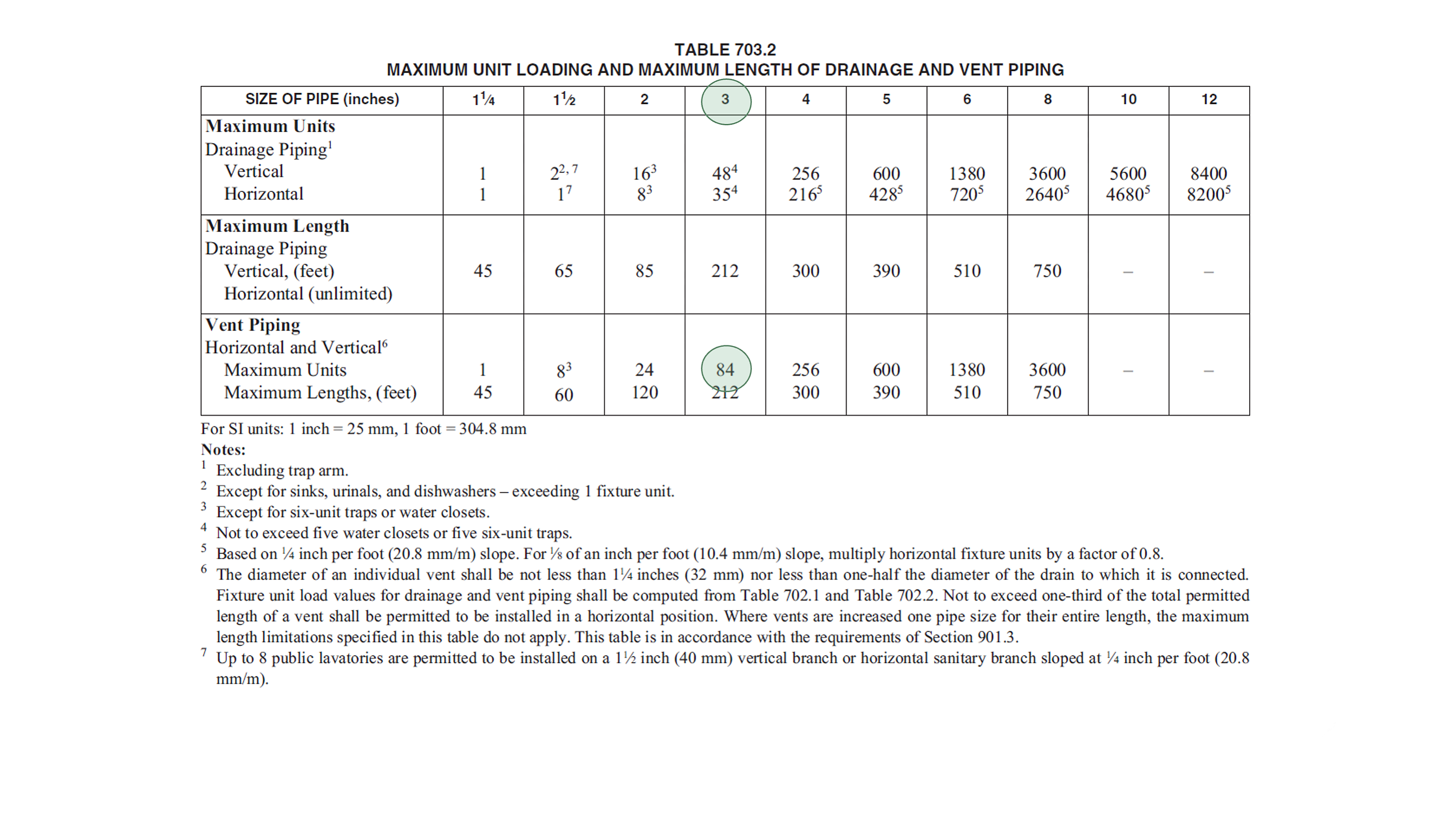

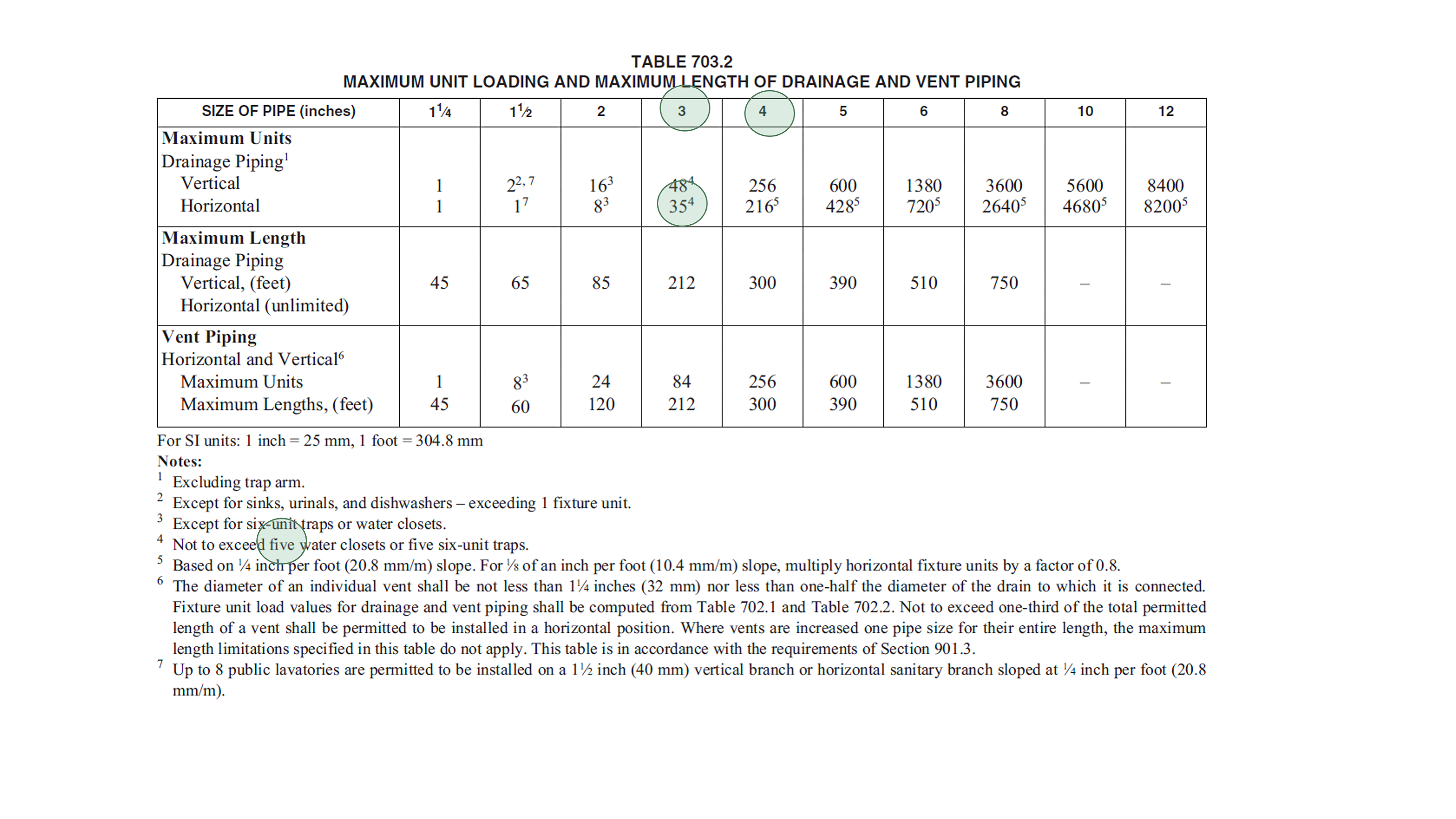

Table 703.2 is used to help figure the problems below.

911.3 Relief Vent. A 2 inch (50 mm) relief vent shall be provided for circuit-vented horizontal branches receiving the discharge of four or more water closets when connecting to a drainage stack that receives the discharge of soil or waste from upper horizontal branches.

Question: What is the minimum size of the horizontal branch drain? Answer 1: (4”) Answer 2: (3”)

Geoff Bilau

Last modified: May 8, 2024