MARCH 14, 2024

From the 2024 UPC Illustrated Training Manual, Chapter 15 – ALTERNATE WATER SOURCES FOR NONPOTABLE APPLICATIONS

1503.2.3 Backwater Valves. Gray water drains subject to backflow shall be provided with a backwater valve so located as to be accessible for inspection and maintenance.

Backwater valves prevent the contamination of the gray water system or surge tank from black water intrusion in the event of a sanitary sewer or building drain stoppages. Backwater valves are designed to be installed in the horizontal position (see Figure 1503.2.3). The use of backwater valves in the vertical position must be installed per the terms of their listing and approved by the AHJ. Equally important is the direction of flow. Many ejector backwater valves are designed for vertical installation, but only when the valve is closed when the pump is not active. Some gray water guidelines portray the valve in the vertical position and stay open unless there is a sewer back up. This installation is not recommended, and the valve will not shut properly when required.

From the 2024 UPC Illustrated Training Manual, Chapter 5 – EXHAUST SYSTEMS

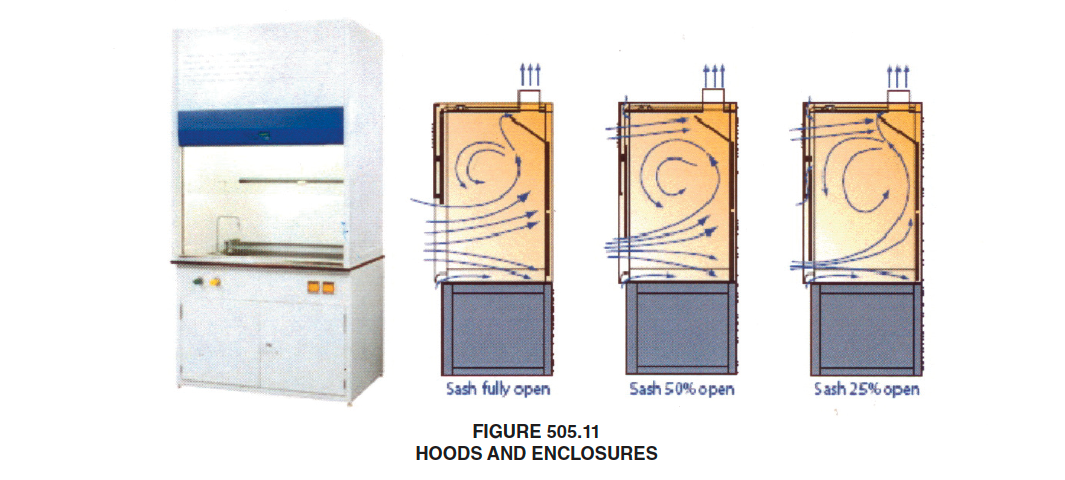

505.11 Hoods and Enclosures. Hoods and enclosures shall be used where contaminants originate in a concentrated area. The design of the hood or enclosure shall be such that air currents created by the exhaust systems will capture the contaminants and transport them directly to the exhaust duct. The volume of air shall be sufficient to dilute explosive or flammable vapors, fumes, or dusts in accordance with Section 505.3. Hoods of steel shall have a base metal thickness not less than 0.027 of an inch (0.686 mm) (No. 22 gauge) for Class 1 and Class 5 metal duct systems; 0.033 of an inch (0.838 mm) (No. 20 gauge) for hoods serving a Class 2 duct system; 0.044 of an inch (1.118 mm) (No. 18 gauge) for hoods serving a Class 3 duct system; and 0.068 of an inch (1.727 mm) (No. 14 gauge) for hoods serving a Class 4 duct system.

Approved nonmetallic hoods and duct systems shall be permitted to be used for Class 5 corrosive systems where the corrosive mixture is nonflammable. Metal hoods used with Class 5 duct systems shall be protected with an approved corrosion-resistant material. Edges of hoods shall be rounded. The minimum clearance between hoods and combustible construction shall be the clearance required by the duct system.

When air contaminants are produced in a concentrated area, hoods and enclosures must be used to capture these contaminants (see Figure 505.11). A concentrated source area is typical of many industrial processes that generate product contaminants. The hood or enclosure design must be such that the air currents created by the exhaust system will capture the contaminants and transport them directly to the exhaust duct. This is usually achieved by creating a partial vacuum within the hood or a slight positive pressure around the hood. The volume of air must be great enough to dilute explosive or flammable vapors, fumes or dusts to below 25 percent of the LFL or lower explosive limit (LEL) of the contaminant. The LFL is unique to each material to be exhausted and is also a function of temperature, humidity and other factors. Research in mines, refineries, chemical and other industrial plants, and farm environments of all types, has led to the current body of scientific knowledge and field experience in what constitutes a “safe lower limit.” Much of this knowledge has been acquired the hard way, through fires, explosions, catastrophic injury and loss of life.

Hoods must be made of steel and must have a base metal thickness as follows:

Class 1 and Class 5 Duct Systems — 22 gauge [0.027 inch]

Class 2 Duct Systems — 20 gauge [0.033 inch]

Class 3 Duct Systems — 18 gauge [0.044 inch)]

Class 4 Duct Systems — 14 gauge [0.068 inch]

Class 5 corrosive systems may use approved nonmetallic hoods only when the corrosive mixture is nonflammable. Metal hoods used in such installations must be protected with corrosion-resistant material.

Hood edges must be rounded. The clearance of hood to combustible construction must not be less than that required for the exhaust duct.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: March 14, 2024