July 6, 2023

From the 2021 UPC Illustrated Training Manual, Chapter 10, TRAPS AND INTERCEPTORS

1009.0 Interceptors (Clarifiers) and Separators.

1009.1 Where Required. Interceptors (clarifiers) (including grease, oil, sand, solid interceptors, etc.) shall be required by the Authority Having Jurisdiction where they are necessary for the proper handling of liquid wastes containing grease, flammable wastes, sand, solids, acid or alkaline substances, or other ingredients harmful to the building drainage system, the public or private sewer, or to public or private sewage disposal.

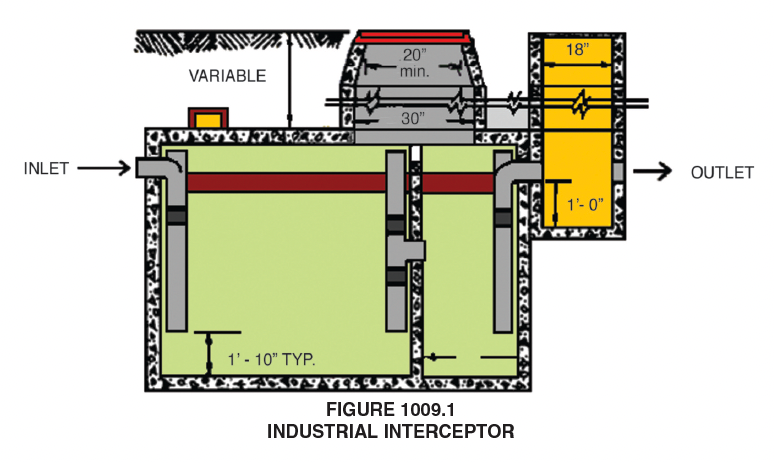

Interceptors and separators serve a different purpose than fixture traps in that they protect the drainage and sewer systems from the introduction of substances that might be harmful to those systems. An interceptor or separator is a device designed and installed to separate, retain and treat deleterious, hazardous and undesirable matter before they enter the sewer system (see Figure 1009.1). Normal sewage or liquid wastes bypass these devices and discharge into the sewer system via the building drain and sewer.

If large amounts of grease, soaps and oils enter a sewer system, the materials will coagulate, solidify and adhere to the inside wall of the pipe, eventually blocking or partially blocking the pipe. Similarly, solids such as sand, plaster, metal chips and stones will cause stoppages or partial stoppages if permitted to enter the system. Oils, kerosene, gasoline, naphtha and paraffin present the danger of fire and explosion in sewer piping. Acids, alkalis and other chemical wastes in concentrated amounts could attack the piping through corrosion. In addition, all of the above are detrimental to proper functioning of sewage treatment plants, both public and private, and must be collected and treated before they discharge to the sewer system.

There are three principal methods of intercepting and treating these unwanted wastes. They are:

1. Floatation. Gasoline, oil, grease and other volatile liquids are lighter than water and are not readily soluble in water. They tend to separate out of the liquid waste and float to the top of the container where they can then be collected and removed. Hydromechanical grease interceptors, gravity grease interceptors and oil or gas interceptors are examples of devices that use floatation as a primary method of separation.

2. Sedimentation. Sand and other solids, which are heavier than water and also are not soluble in water, tend to settle out of the waste water to the bottom of the container. The solids can then be pumped or vacuumed out of the interceptor. Sand interceptors, septic tanks and drum traps for smaller installations are examples of devices that use sedimentation as the primary method of separation.

3. Neutralization. Chemical wastes that could be detrimental to the sewage system in concentrated amounts must be neutralized before entering the sewer system. Chemical waste is collected before entry into the sewer and treated or neutralized before being discharged to the sewer. Acid neutralizing tanks and other such devices are examples of systems that use neutralization as the primary method of separation.

Occasionally, waste with high concentrations of grease or emulsified grease may require further treatment, such as additional settling, rock filtration and chemical or mechanical treatment to remove the grease. There are many instances where one of the three methods or a combination of methods for treating these wastes is needed.

Examples of the use of these devices are: restaurants, hotels, cafeterias, schools, hospitals and institutional or commercial buildings where food is served in great quantity may produce grease in sufficient amounts to warrant the installation of grease interceptors; dairies, slaughterhouses and commercial food-processing plants have grease and fats as byproducts and require interceptors; gasoline service stations, garages, automobile repair shops, laundries, dry-cleaning plants, machine shops and industries using chemical processing are sources of flammable and volatile wastes that must be removed and treated; machine shops, garages, service stations, hospitals, medical clinics, dental laboratories and fish preparation areas contribute solids such as metals, plaster, sand and fish scales; hair and lint interceptors may be necessary in beauty salons, barbershops, surgical preparation rooms and veterinary facilities; and dental laboratories and jewelry manufacturers may require interceptors for the recovery of precious metals.

Separators and interceptors will be designed by the manufacturer and the installation location designated by a plumbing engineer or design professional. The plumber’s or plumbing contractor’s responsibility is to install the system properly. In addition to the manufacturer’s installation instructions, the following sections provide guidance for the installation of the interceptor or separator.

The 2021 Uniform Plumbing Code Illustrated Training Manual is available for purchase here.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: July 6, 2023