Since 1926, IAPMO has been protecting public health and safety with the development of its codes and standards. When it comes to the latest technology, IAPMO excels and is ahead of the curve. When it comes to the latest technology, IAPMO excels and is ahead of the curve. Many products that are now part of our daily lives originated as an IAPMO standard, such as the IAPMO Z124 for plastic plumbing fixtures, IAPMO Z401 for glass lavatories, and IAPMO Z403 for terrazzo plumbing fixtures, to name just a few. Many organizations also look to partner with IAPMO for harmonization or adoption

of their standards. These partnerships lead to the harmonized standards: CSA B45.5/ IAPMO Z124, CSA B45.8/IAPMO Z403, CSA B45.11/IAPMO Z401, or CSA B45.12/ IAPMO Z402. Others include the ASPE/IAPMO Z1034 standard for testing and evaluating roof drain performance. IAPMO believes it is crucially important that organizations work together for the common good of the industry.

IAPMO is the most trusted and recognized name in the plumbing industry for lavatories, water closets, showers, sinks and urinals, and for the plumbing codes. The IAPMO Z standards, the Uniform Plumbing Code (UPC) and the Uniform Mechanical Code (UMC) are developed via an ANSI-approved development process. ANSI stands for the American National Standards Institute and it is a third-party entity that assures a fair, balanced and consensus development process. IAPMO is the only organization that can claim the ANSI designation for its plumbing and mechanical codes. If a development process approved by ANSI is not utilized in the development process, then the process can be dominated by a single constituent. IAPMO prides itself on this distinction from other plumbing and mechanical codes.

When a new and novel product comes to the market, the industry must have confidence that the product will function as intended, but most importantly, that it is safe. Over time, IAPMO standards have become widely accepted in various jurisdictions around the nation and other parts of the world. In fact, these standards are so crucial that some organizations have borrowed language from them to be implemented into their codes or standards. However, it is important to emphasize that IAPMO standards are protected by copyright laws. IAPMO believes collaboration is key and necessary to avoid confusion. Therefore, IAPMO welcomes any harmonization efforts as they only benefit the industry.

As stated above, IAPMO is ahead of the curve when it comes to the latest technologies. Let us take a look at some examples of how IAPMO addresses the latest technologies in its codes and standards:

IAPMO/ANSI Z1349 (Devices for Detection, Monitoring or Control of Plumbing Systems)

In 1997, IAPMO first addressed this concept in its standard for leak detection as IGC 115 (Automatic Water Leak Detection System) and IGC 349 (Electric Plumbing Supply System Integrity Protection Devices). In October 2020, after a three-year effort by task groups and committee members, the final draft of IAPMO Z1349 standard was approved by the Plumbing Standards Committee (PSC) as a standard. The PSC is a balance body for plumbing standards that is governed by an ANSI-approved standards development process.

This water-leak-detection technology has the capability of letting the homeowner know if there is a water leak with the use of a smartphone. Aside from preserving resources, a homeowner will save money on their water bill and insurance companies can have peace of mind that water leaks will be detected prior to causing major damage to the structure. Aside from damage to the structure, leaks that are not properly fixed can cause mold to grow.

The IAPMO Z1349 standard covers devices for detection, monitoring or control of water supply and distribution systems for commercial and residential applications and specifies requirements for materials, performance testing, environmental limitations, installation, and markings.

Devices for detection, monitoring or control of plumbing systems covered by this standard govern plumbing systems through features such as:

(a) Automatic shut-off or electronic alarm notification or isolation of the supply piping when conditions are detected indicating a leak or equipment malfunction (e.g. automatic water leak detection and control device).

(b) Detecting the presence of water external to the piping system.

(c) Establishing normal water flow patterns and monitoring for anomalies.

(d) Monitoring of the hydraulic conditions (e.g. water pressure, temperature, or flow) within the main or branch circuit.

(e) Monitoring of the local environment that may indicate potential for freeze conditions; or

(f) Monitoring of the local environment for moisture that may indicate a leak (e.g. Physical Water/Moisture Detection Devices).

(g) Monitoring of environmental conditions.

(h) Ongoing analysis of sensor readings or system conditions to ensure monitoring of system integrity.

(i) Pressure based or other means of micro leak testing for detection of pinhole leaks or dripping fixtures; or,

(j) Provide hardwired or remote access to control a valve (e.g. remotely controlled valves)

The previous version of the standard (IGC 115 and IGC 349) is currently reference in the Uniform Plumbing Code, Section 606.9. Section 606.9 of the 2021 Uniform Plumbing Code (UPC) states the following:

606.9 Leak Detection Devices. Where leak detection devices for water supply and distribution are installed, they shall comply with IAPMO IGC 115 or IAPMO IGC 349.

IAPMO IGC 332 (Alkaline Water-Drinking Water Treatment Units)

The IGC 322 was first published in 2018 and it covers alkaline water — drinking water treatment units intended for use in residential, commercial and food service applications and specifies requirements for materials, performance tests and markings.

One thing you will noticed is that, during this pandemic, many are getting water using water filtration facilities. At these facilities, many get alkaline water due to its benefits. Some have opted to have these products at home.

One of the concerns by jurisdictions was there was not a standard available to address these products. With the assistance of stakeholders, IAPMO addressed this gap and generated the IGC 322 standard.

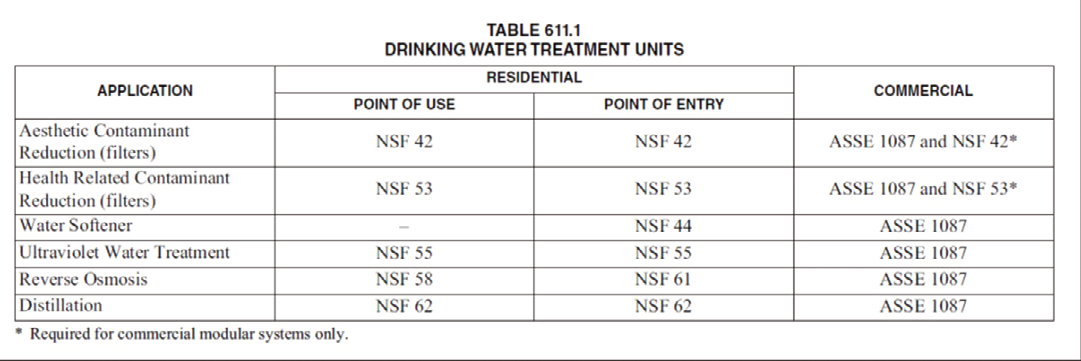

Furthermore, the Uniform Plumbing Code (UPC) then followed by addressing this

product in Section 611.1.1, which states the following:

611.1.1 Alkaline Water Treatment. Alkaline water treatment devices shall comply with IAPMO IGC 322.

IAPMO PS 106 (Tileable Shower Receptors and Shower Kits):

Though this is not your typical new technology, this standard addresses a common product being utilized in the field. The PS 106 standard was first published in 1998 and it specifies requirements for materials and physical characteristics for tileable shower receptor and shower kits. Performance testing for prefabricated, tileable shower receptor, and tileable and pre-tiled shower kits intended to be assembled in the place of final installation are also addressed within the standard. The PS 106 standard addresses the material, wall thickness, drains and outlet, liners and coatings and sealants of such installations.

Those looking for guidance in the installation of tileable shower receptors and shower kits should turn to the IAPMO PS 106 standard.

For this reason, entrepreneurs and organizations bring their novel products to IAPMO so that they can be more accepted by authorities having jurisdiction. Many of the products addressed by IAPMO standards have not been seen before but are important for advancing society forward. And, most importantly, these standards ensure the products are safe for public use.

The IAPMO Z standards, the Uniform Plumbing Code® (UPC®) and the Uniform Mechanical Code® (UMC®) are developed via an ANSI approved development process. ANSI stands for the American National Standards Institute and it is a third-party entity that assure a fair, balance, and consensus development process.

Let us take a look at some additional examples on how IAPMO addresses the latest technologies in its codes and standards that advance society forward while protecting the public.

IAPMO IGC 154 (Shower and Tub/Shower Enclosures, Bathtubs with Glass Pressure-Sealed Doors, and Shower/Steam Panels)

The IAPMO IGC 154 standard was published in 2000 and covers shower/steam panels,

enclosures for showers and tub/shower combinations, bathtubs and tub/shower combinations with glass pressure-sealed doors, and floor-mounted showers intended for new and retrofit applications, as well as specifies requirements for materials, physical characteristics, performance testing, and markings. This standard allows the opportunity to test the shower controls, joints, fittings, walls, and appurtenances as an assembly in a lab to confirm compliance.

In addition to covering the shower receptors and bases, IAPMO IGC 154 includes requirements for the evaluation of shower panes, such as the glass doors, or clear plastic walls commonly installed in the field and are not currently addressed in the code. Shower panes covered under IAPMO IGC 154 are required to comply with minimum performance requirements for panes, such as “tempered or laminated safety glass” and “architectural glazing material,” guiding the installer and authority having jurisdiction in ensuring installations of these shower enclosures meet minimum standards for a safer and more reliable system.

Furthermore, the Technical Committee for the UPC recognized the importance of this standard and recently approved it for reference into the 2021 UPC, Section 408.1.

408.0 Showers.

408.1 Application. Manufactured shower receptors and shower bases shall comply with ASME A112.19.1/CSA B45.2, ASME A112.19.2/CSA B45.1, ASME A112.19.3/CSAB45.4, CSA B45.12/IAPMO Z402, or CSA B45.5/IAPMO Z124. Prefabricated shower enclosures shall comply with IAPMO IGC 154.

IAPMO IGC 127 (Combined Hand-Washing Systems)

First published in 1998, the IAPMO IGC 127 standard covers combined hand-washing

systems comprised of electronically actuated soap dispensers, faucets, and hand air-dryers, and specifies requirements for materials, physical characteristics, performance testing, and markings.

Products listed to IAPMO IGC 127 can be a good solution to limit contact exposure as they offer touch free exposure for the use of soap dispensing, hand washing, and/or drying as a combined system.

The Technical Committee for the UPC recognized this need and the potential advantages by approving its reference in the 2021 edition of the UPC (Section 407.1). Due to the COVID-19 pandemic, Jurisdictions throughout the nation are seeing these products being installed to limit the contact with materials.

407.0 Lavatories.

407.1 Application. Lavatories shall comply with ASME A112.19.1/CSA B45.2, ASME A112.19.2/CSA B45.1, ASME A112.19.3/CSA B45.4, ASME A112.19.12, CSA B45.5/IAPMO Z124, CSA B45.8/IAPMO Z403, CSA B45.11/IAPMO Z401 or CSA B45.12/IAPMO Z402. Group wash fixtures shall comply with the requirements of Section 401.2. Every 20 inches (508 mm) of rim space of a group wash fixture shall be considered as one lavatory for determining the number of lavatories required in accordance with Table 422.1. Lavatory assemblies with automatic soap dispensers, faucets, or hand dryers shall comply with IAPMO IGC 127.

IAPMO Z1001 (Prefabricated Gravity Grease Interceptors)

First published in 2007, the IAPMO Z1001 standard covers prefabricated gravity grease interceptors made of concrete, fiber-reinforced polyester (FRP), thermoplastic, or steel and specifies requirements for design, materials, performance, testing, and markings. A gravity grease interceptor is a large volume tank constructed of steel, concrete, fiberglass, or plastic. It separates FOG from wastewater by gravity alone. The FOG-entrained wastewater enters the tank using tee baffles to direct the flow below the floating FOG level in order to leave the floating FOG undisturbed. Retention time is used to separate the FOG from the wastewater by floatation. According to the UPC, a FOG disposal system is a grease interceptor that reduces nonpetroleum fats, oils, and grease (FOG) in the effluent by separation, mass, and volume reduction.

The UPC gives guidance to the design, location, and installation of the gravity grease interceptor. The IAPMO Z1001 standard is referenced in the UPC (Section 1014.3.4) as one of the acceptable standards for these types of products.

1014.0 Grease Interceptors.

1014.3.4 Location. Each grease interceptor shall be so installed and connected that it shall be easily accessible for inspection, cleaning, and removal of the intercepted grease. A gravity grease interceptor that complies with IAPMO Z1001 shall not be installed in a building where food is handled. Location of the grease interceptor shall meet the approval of the Authority Having Jurisdiction.

When a new and novel product comes to the market, the industry must have confidence that the product will function as intended, but most importantly, it is safe. Over time, IAPMO standards have become widely accepted in various Jurisdictions around the nation and other parts of the world.

If you are looking to create a standard for your novel product, IAPMO can assist in this effort. The industry looks to IAPMO for its entire product standard needs. Visit iapmo.org for more information.

In a series of articles, I will be informing the public of our various standards that assist in moving society forward. Please look forward to the next article where more information on new concepts and technologies will be provided.

Hugo Aguilar, P.E.

Last modified: December 29, 2022