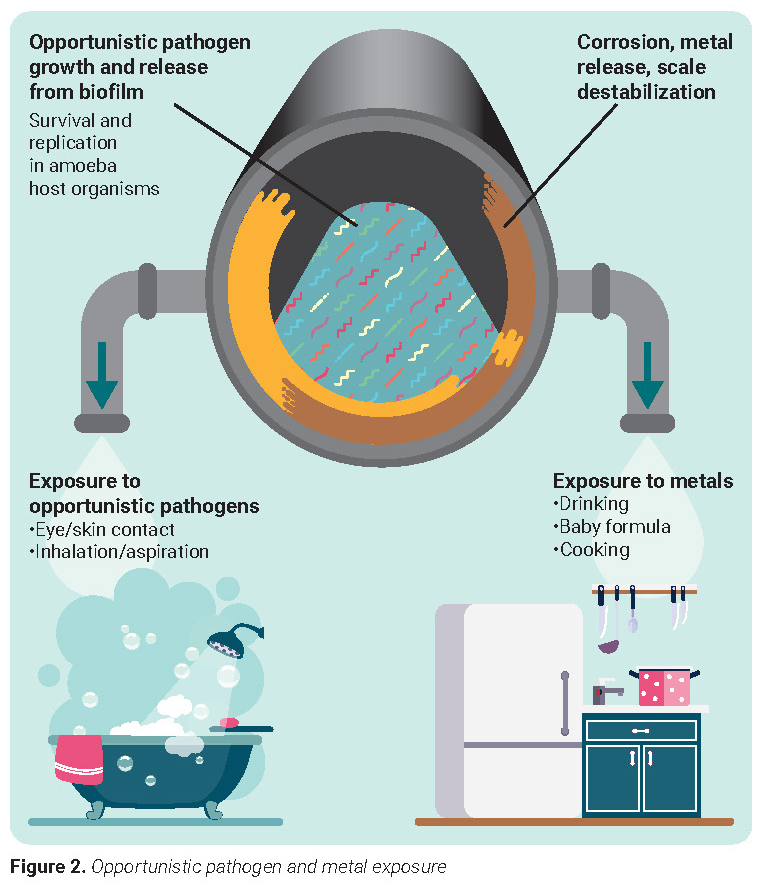

Premise plumbing falls outside the responsibility of drinking water systems and has unique characteristics that render it more complex than the main distribution system. Recognizing these complexities, water systems can communicate information and help building owners and residents address premise plumbing’s numerous challenges:

- Stagnant water

- Disinfectant decay

- Disinfection byproduct formation

- Corrosion

- Metal release

Reflecting the need to preserve water quality until it reaches consumer taps, AWWA adopted a policy statement on premise plumbing in 2018 (https://news.awwa.org/ PremisePlumbing) that stresses two points:

- AWWA encourages water systems to establish comprehensive policies and operational goals that are designed to protect water quality in premise plumbing.

- AWWA supports and encourages collaboration among water systems, public health agencies, property owners, and other stakeholders to develop measures for maintaining water quality that meets or surpasses regulatory standards and requirements in premise plumbing.

To help accomplish the policy’s goals, an AWWA subcommittee was created — Premise Plumbing: Beyond the Meter — under the AWWA Distribution System Water Quality Committee. It became an independent AWWA committee in early 2020. The committee’s mission statement is “to synthesize industry knowledge and convey information that improves building water quality.”

The Premise Plumbing Committee now has approximately 120 members, representing academia, consultants, equipment providers, industrial partners, federal and local governments, and several groups outside of the association. Topics of interest to the Premise Plumbing Committee come from questions posed by AWWA members:

- How can we control microbial regrowth (e.g., nitrification and Legionella) in buildings?

- How can we control inorganic contaminants (e.g., lead and copper)?

- How can we clean premise plumbing from accumulated inorganic contaminants?

- How can we improve water quality in hot water systems?

- How should premise plumbing be handled, considering it falls in the nonutility-owned portion of the service line?

- How has the COVID-19 pandemic affected building hydraulics and water quality?

Pressing Challenges

These topics present significant challenges and are being addressed by various subcommittees. We asked subcommittee members to reflect on their most pressing challenges. Interestingly, members of the Lead-in-Water Subcommittee and the Copper-in-Water Subcommittee reported contrasting challenges, as presented by their representatives.

Lead-in-Water Subcommittee

In the United States, the revisions to the Lead and Copper Rule (LCR), which celebrated its 30th anniversary in 2021, have caused many restless nights. The LCR Revisions (LCRR) were proposed in 2019, finalized in 2021, and subsequently held for review five days after publication in the Federal Register. Both the effective and compliance dates were then extended and delayed again. The U.S. Environmental Protection Agency (EPA) announced on Dec. 16, 2021, that the regulation will go into effect on that same day, as published earlier in the year, and EPA is expected to develop a new rule, the Lead and Copper Rule Improvements. These changes have kept many of us, particularly water systems, on our toes.

With many questions remaining, the uncertainty of the effective date and the content of the final LCRR that lasted through most of 2021 has made it difficult for water systems to properly prepare for compliance with the revised regulation. The changes have not made the rule any less complicated, and many water system staff who were around for the initial implementation have since retired, taking their institutional knowledge with them. As a result, there is a need for education or reeducation of corrosion control treatment (CCT). For some systems, CCT may have been set 30 years ago and not changed much since. With the lead-related issues encountered in Flint, Michigan, fresh in everyone’s minds, many water systems are proceeding cautiously on these regulatory requirements.

Many AWWA committee members and industry groups have been working to better understand how the LCRR will affect their stakeholders, in particular clarifying the sometimes confusing language. AWWA openly shares this information with its members through fostered discussions like committee meetings, presentations, conference proceedings, webinars, articles, and online courses. The efforts to share LCRR knowledge and understanding have fostered a community of individuals with a common goal of working together to understand and comply with the revisions as well as share what they have learned with others. Whether the LCRR has kept us on our toes or up at night, at least we have not been alone.

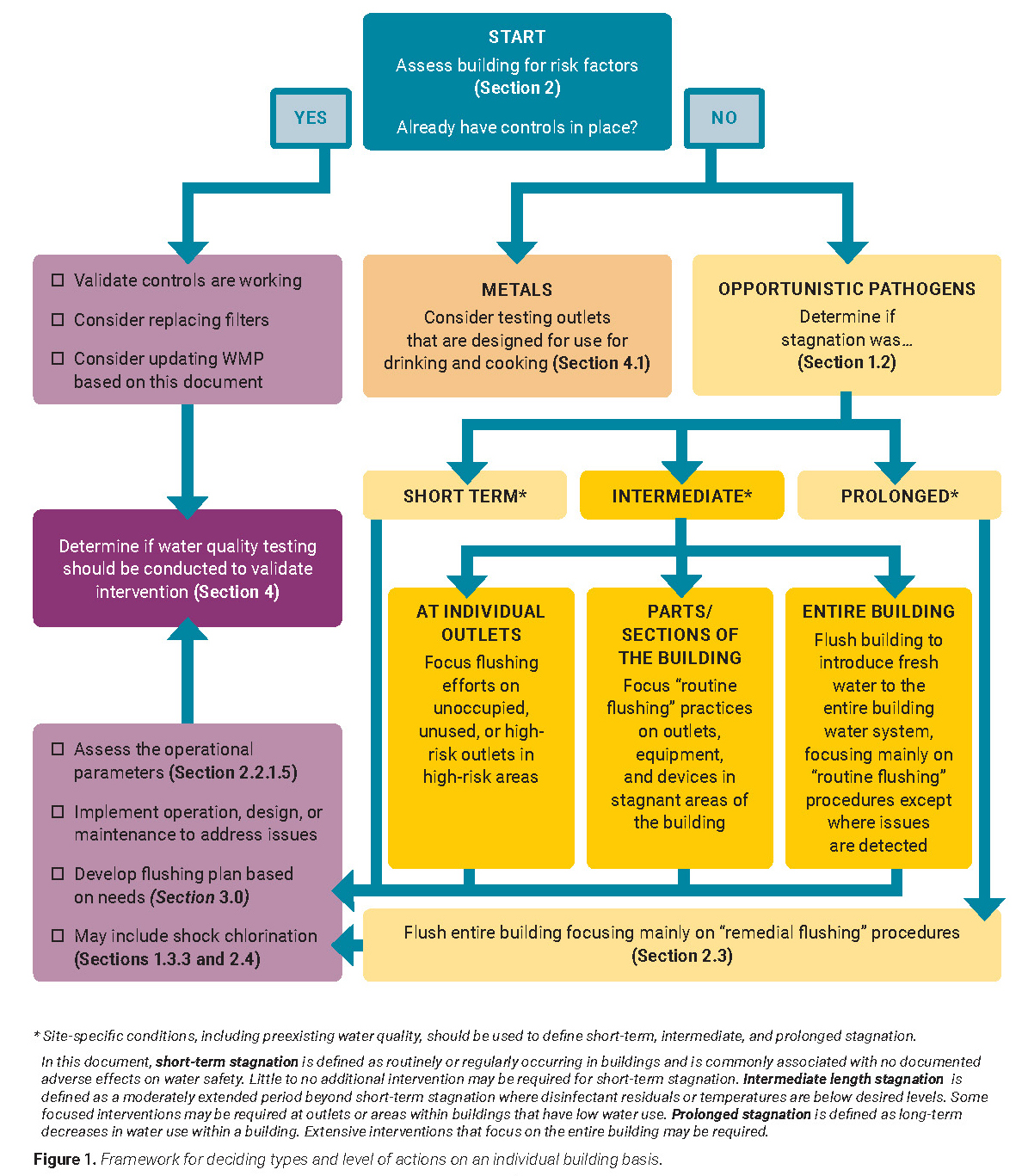

GRAPHICS COURTESY OF AWWA

SOURCED FROM “RESPONDING TO WATER STAGNATION IN BUILDINGS WITH REDUCED OR NO WATER USE”

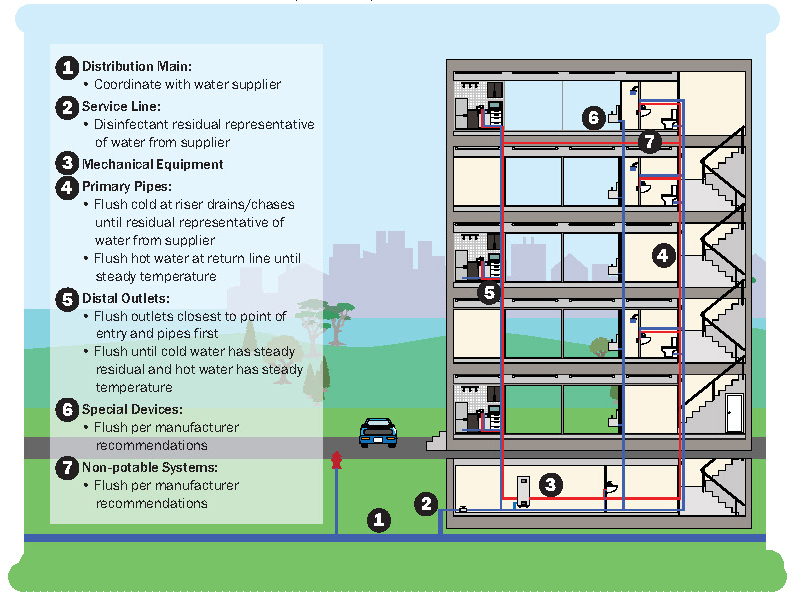

GRAPHIC COURTESY OF EPA

Copper-in-Water Subcommittee

Relative to other hot topics, problems related to copper corrosion seem to be mostly overlooked, making it more challenging to identify and address the issues. Although the basics of copper corrosion are relatively well understood, questions and confusion on water-sampling site selection and protocol are still raised by many stakeholders. Particularly in large buildings, it is puzzling as to which of the many water outlets best represents the highest copper levels.

Some communities still struggle to identify effective measures to address problems with high copper levels and pitting corrosion. There is also a lack of case studies and datato guide utilities and other stakeholders. Copper problems may be compounded by the fact that the LCRR has shifted focus to sampling homes with lead service lines. Copper and lead have different corrosion mechanisms, so changes in treatment or source water could have unintended consequences with regard to copper corrosion problems.

The water industry needs to provide better guidance for stakeholders to address copper issues when their systems undergo water quality changes. Our desire to bridge this gap brought a group together that includes plumbing design engineers, scientists, and academics. As AWWA volunteers, we work to improve how water professionals understand plumbing design and codes, water chemistry and treatment, and the nature and mechanisms of copper corrosion. To communicate our findings as broadly as possible, we have published articles in AWWA and external publications. The Copper-in-Water Subcommittee will continue to narrow any knowledge gaps and respond to questions concerning the control of copper in drinking water.

Building Disinfection Subcommittee

Narrowing knowledge gaps is a common theme among the Premise Plumbing Committee’s subcommittees, and it applies to the Building Disinfection Subcommittee, as well. Plumbing codes require that new or renovated (i.e., repaired) building water systems must be flushed and disinfected before they can be legally occupied. Although the International Plumbing Code and Uniform Plumbing Code provide general requirements for flushing and disinfection, they lack detailed protocols for how to perform and validate these procedures.

To meet code, plumbing design engineers currently cite AWWA C651, Disinfection of Water Mains, or C652, Disinfection of Storage Facilities, as methods for disinfecting a premise’s water system before it is occupied. However, neither of these standards is intended to be applied in building plumbing systems. In fact, recent updates of both standards have explicitly stated that they are not to be used for building plumbing system disinfection, leaving plumbing design engineers and disinfection contractors at a loss for a reference method.

To fill this gap that has historically (and unintentionally) been filled via AWWA C651 and C652, the Building Disinfection Subcommittee is drafting building-specific guidance for flushing and disinfecting newly constructed or renovated buildings. The

guidance will detail how to avoid the most common pitfalls encountered when performing pre-occupancy flushing and disinfection, such as inadequately purging the system of construction-related deleterious matter and slug-dosing disinfectants that may result in uncontrolled high (or low) levels of disinfectant that can damage the system or provide inadequate disinfection. The guidance will also include recommendations for assessing the disinfection protocol’s success through microbiological measurements. Intended for publication as an AWWA technical report, the guidance will provide a reference for building specifications so design engineers, disinfecting contractors, and building owners can sleep a little better at night.

Additional Efforts

The Premise Plumbing Committee is beginning to address additional issues that keep committee members up at night through two new workgroups. One workgroup is exploring how to improve operations of building water systems to preserve water quality. This need arose after considering that these systems have become more complex over the past few decades and that conditions (including hydraulics) in building water systems are different from those in distribution systems.

Another workgroup is looking at the water–energy nexus. Although several organizations are already working on this topic, the AWWA workgroup has observed that water quality is often a neglected component of these discussions. Therefore, this workgroup is exploring options to narrow the gaps within the broader industry and elevate water quality in water–energy nexus discussions. These are some of the important challenges on the minds of Premise Plumbing Committee volunteers.

Reprinted with AWWA Permission from Journal AWWA April 2022.

AWWA Premise Plumbing Committee

Last modified: May 8, 2024