The American Council for an Energy Efficient Economy welcomed more than than 230 virtual attendees to a forum that stressed water safety, infrastructure development and more.

The American Council for an Energy Efficient Economy held it’s 13th annual Hot Water Forum this March 10-11 and March 17-18. The virtual event—promoted as the preeminent annual conference on water heating—attracted over over 230 attendees and featured more than 60 speakers with a wide range of perspectives. In addition to sessions the forum included plenaries, 16 break-out sessions, and networking opportunities throughout each day.

The forum brought together a diverse group of equipment and component manufacturers; water, gas, and electric utility professionals; local, state, and federal agency personnel; energy efficiency program planners, operators, and evaluators; plumbers and installers; policymakers; NGOs; engineers, and consultants. (Click for a full list of participating organizations. A full list of event sponsors can be viewed at the end of this article.)

Opening Plenary

Chris Perry, Research Manager, Building Program, ACEEE, opened the forum by welcoming attendees. He then gave the microphone to Joshua C. Greene, Esq. Corporate Vice President – Government and Industry Affairs for A. O. Smith Corporation.

Green said A. O. Smith was delighted to be a platinum sponsor of the event, the outgrowth of a decades-long partnership with the ACEEE. The event, he said, reflected the founding principles of the Smith family which included both good citizenship and responsibility for the environment. “I am looking forward to a lot of the content, and to your interaction and participation,” Green said.

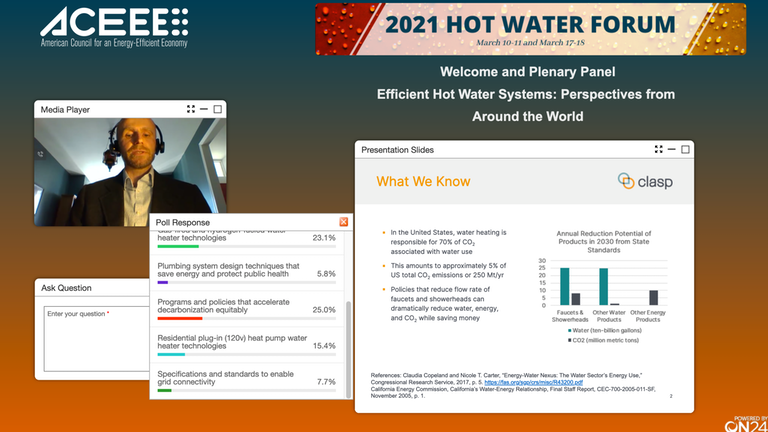

Matt Malinowski, Sr. Manager, Climate for CLASP (an NGO that seeks to improve the efficiencies of everyday appliances and equipment) then took to the virtual podium to moderate the opening plenary, Efficient Hot Water Systems: Perspectives from Around the World. Panelists included Adrie Fourie, Sr. Sustainable Building Consultant, Solid Green Consulting; Mohit Verma, Associate Director, Environmental Design Solutions; and Richard Lambert, Program Manager, Standards Australia.

The discussion immediately put water heating into a global context by addressing the role it plays in CO2 emissions (roughly 5 percent of the total for the US). After a brief summary of different labeling standards in the US (including DOE, EPA WaterSense and CalGreen), Malinowski brought things around to the main topic for the panel: how do we apply what we have learned about water technology and smart water policy to benefit people around the world?

Over the course of the next hour, the panelists provided a range of answers. Fourie examined the current state of water policy in South Africa, which is complicated by “right to water” laws (which have a larger impact in times of drought), and limited, patchwork enforcement of the South Africa Bureau of Standards water efficiency labeling. It is speculated that a more coherent, nationwide policy could reduce water use by 1 Trillion L. per year.

Verma gave an outline of the situation in India, where his company, Environmental Design Solutions works on water policy with an array of public and private stakeholders. Currently, the nation is working on providing water metering to as many households as possible, striving to develop a unified National Plumbing Code, and promoting a voluntary labeling program (in the model of WaterSense). The labeling program, in particular, has been making good progress. Green building certification will also have an important role to play moving forward.

Lambert talked about the state of water policy in Australia, which is also working to create its own water efficiency labeling programs. There the program is not intended to introduce new requirements, but instead to reference existing national product standards. In implementing the standard, Lambert admitted there is, “A long road ahead… but it is hoped that it will influence consumers, manufacturers and various governing bodies around the globe.”

The panel discussion continued and included a Q & A section with attendees. Key concerns were evaluating the effectiveness of such standards, and creating an international framework for collaboration and sharing best practices.

Legionella and Sustainability

Over the course of the Hot Water Forum, programming included sessions on large hot water system design, the transformation of the heat pump water heater market, how utility programs can best serve low-income communities, decarbonizing the gas grid and much more (click for a full list of sessions).

Wednesday, March 17th saw the presentation of Legionella and Hot Water: Balancing Health and Sustainability, a session that looked at the value of hot water as a method of Legionella mitigation, hot water design considerations, hot water return balancing considerations, as well as the latest associated codes, standards and guidelines.

Moderating and presenting the session was Christoph Lohr, PE, Vice President of Strategic Initiatives at IAPMO. The two speakers were Scott Wolber, Director of Engineering and Maile Akina, Sr. Director of Business for LiquiTech, a water security company.

Lohr, in addition to his role with IAPMO, is chair of the ASPE Legionella Working Group, making him ideally positioned to speak on the topic. He began his presentation by noting what a very complex topic the study of Legionella and its mitigation can be. Many different factors, including water temperature, turbidity, surface area, nutrients are involved and inter-related.

Lohr also stressed the difference between data from laboratory studies, and data collected from the field (actual, in-use systems). For example, while 160 degree F water will kill all Legionella bacteria in a laboratory setting, that setting will rarely reflect the biofilm or scale that may be protecting the bacteria in the field.

Lohr outlined the Handy-Cross methodology of system design which allows the designer to solve for multi-loop network flows that cannot be solved by an closed-loop equation. Computer programs based on the Handy-Cross method make assumptions for certain variables and the designer must, necessarily, work through multiple iterations to find the best solution. As balancing the system becomes more and more complex, commissioning the system becomes ever more important.

Pump selection is also a key factor, as pumps can be very easily over- or under-sized. Lohr encourages the use of VFD pumps with a manual setpoint for flow and head and then dial that setpoint in.

Lohr shared several lessons he had learned over the course of his hot water career. For instance, it is possible to prevent dead-heads—a major factor in Legionella bloom—using multiple pressure zones, with re-heaters to prevent temperature loss in individual zones that need it.

Given the emergence from the pandemic, there are a number of codes and standards in the works that focus on resilience. AWWA in conjunction with IAPMO, are about to release a manual on re-occupying buildings. ASPE is developing a new Legionella guideline that will be released for review in Q3. There is a lot of new information coming out with a particular focus on hospitals and long-term care facilities.

Scott Wolber then took over the presentation to discuss high temperatures and Legionella control. Just how effective are high temperatures, and what are the economic implications? Wolber stressed that increased temperatures are not a control, only a risk-reduction strategy. Even with 60 minutes of contact time with 160 degree F water there can still be surviving bacteria.

Wolber listed out the top design considerations for mitigation:

- Water heater capacity

- Insulation

- Scalding

- Lead release

- Scale

- Increased demand on pumping infrastructure

- Recirculation pump size

- Velocity limitations and pipe size

- Oxidizing agents

Wolber went on to make several important points.

First, respect the insulation requirements. Anything over 140 degrees F will need 1.5″ thick insulation to prevent heat loss during distribution.

To prevent scalding you cannot deliver 140-160 degree water directly to occupants; you will need thermostatic mixing valves across the building for every point of use, and that can get expensive. Also, many TMVs do not last past 3-5 years, which can increase the cost of maintenance.

Increase water temperatures and you will increase leeching of the base material, and that can mean lead release in many systems. Hot water is just more corrosive. That means hotter systems will also produce more scale, which can have serious, long-term effects on water heating efficiencies as well as distribution efficiencies.

Wolber then went into a cost breakdowns for high-temperature systems (including the cost of energy, added insulation, maintenance etc.).

Then Wolber discussed the use of a copper-silver ionization system to effectively mitigate Legionella at lower water temperatures. [Editor’s note: LiquiTech is a designer and supplier of copper-silver ionization systems.] Those lower temperatures can not only save on energy use, but can be an important part of meeting various green building requirements (such as LEED). Wolber noted that copper-silver systems have been peer-reviewed for effectiveness, and are safe for potable water applications, easy to maintain, and do not increase corrosion.

Copper-silver ionization systems work by passing water through flow cell chambers where direct current is applied across electrodes. The free ions then “seek out” Legionella throughout the water system to destroy the cell walls of the bacteria. The ions will even penetrate the biofilm.

The discussion then moved into a Q&A section.

ACEEE’s Hot Water Forum Sponsors

Platinum

A. O. Smith

Gold

Energize Connecticut

Eversource

Mitsubishi Electric

NEEA

The United Illuminating Company

Silver

Bradford White

Jackson EMC

SoCalGas

Energy Efficiency Education Partner

Southern California Edison

Media Partner

openADR Alliance

Article republished with Permission of Contractor Magazine – Author: Steve Spalding

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: December 30, 2022