October 30, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 6, WATER SUPPLY AND DISTRIBUTION

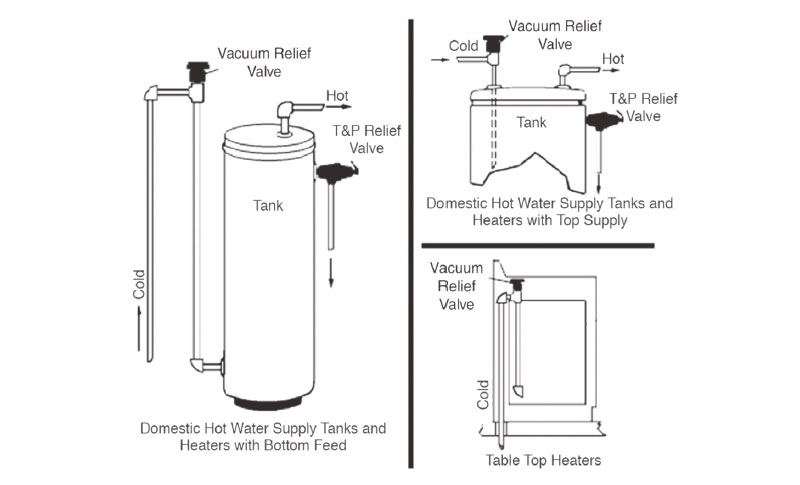

608.7 Vacuum Relief Valves. Where a hot-water storage tank or an indirect water heater is located at an elevation above the fixture outlets in the hot-water system, a vacuum relief valve that complies with ANSI Z21.22/CSA 4.4 shall be installed on the storage tank or heater.

If the water heater is installed above fixtures, there is a possibility of siphonage from the water heater. If the water supply is turned off or pressure drops as fixtures are being used, there is a possibility of a siphon being created because of the fixture water supply opening being lower than the tank. This could result in the tank emptying and possible steam being created in the tank. There have been instances where this siphonic action has been so powerful as to collapse the tank. For these reasons, a vacuum relief valve must be installed (see Figure 608.7).

VACUUM RELIEF VALVE INSTALLATION

From the 2024 UMC Illustrated Training Manual, Chapter 6, DUCT SYSTEMS

606.1 Smoke Dampers. Smoke dampers shall comply with UL 555S, and shall be installed in accordance with the manufacturer’s installation instructions where required by the building code.

Air conveyance systems (ducts) represent a significant source of transmitting smoke and heat throughout a building in a fire situation. Smoke dampers are intended for installation in ducts and air transfer openings that are designed to resist the passage of air and smoke. The devices are installed to operate automatically, be controlled by a smoke detection system and, where required, be allowed to be positioned from a remote command station. Accordingly, smoke dampers are required to reduce — if not eliminate — this risk in buildings where timely evacuation is not always feasible.

Smoke dampers may be required where ducts penetrate though smoke barriers, or at other locations within an engineered smoke control system. A smoke barrier is a continuous membrane, either vertical or horizontal, such as a wall, floor or ceiling assembly, which is designed and constructed to restrict the movement of smoke. Smoke dampers can be used in heating, ventilating, and air-conditioning (HVAC) systems where the fans are shut down in the event of fire, and can also be used in smoke control systems designed to operate during a fire incident. Smoke dampers are designed to operate against air velocity and fan pressure.

To meet the requirements of the UMC and the building code of the jurisdiction, these smoke dampers must meet specific standards of performance, including fire tests. UL 555S tests the damper under simulated fire conditions of elevated temperatures, [250 to 350°F (121°C to 177°C)] and under simulated airflow rates and pressures.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: October 30, 2025