May 8, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 3, GENERAL REGULATIONS

310.5 Obstruction of Flow. No fitting, fixture and piping connection, appliance, device, or method of installation that obstructs or retards the flow of water, wastes, sewage, or air in the drainage or venting systems, in an amount exceeding the normal frictional resistance to flow, shall be used unless it is indicated as acceptable in this code or is approved in accordance with Section 301.2 of this code. The enlargement of a 3 inch (80 mm) closet bend or stub to 4 inches (100 mm) shall not be considered an obstruction.

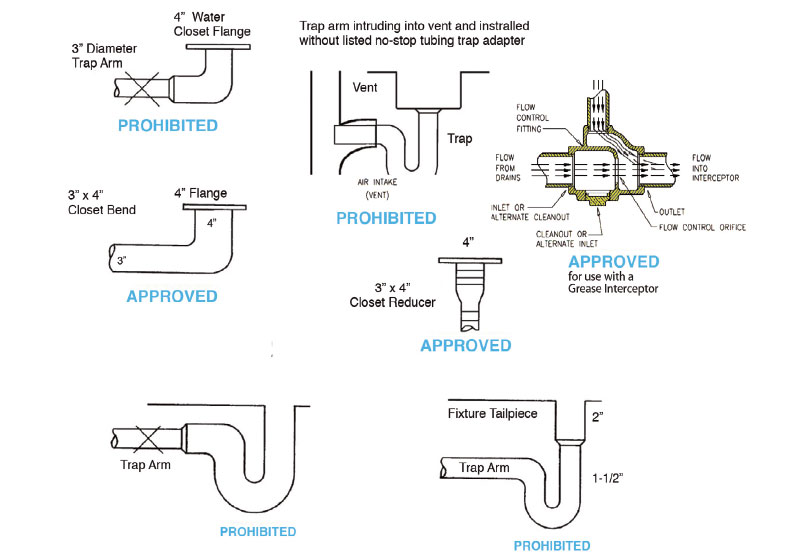

Any installation that causes an obstruction to occur in any part of the plumbing system is prohibited. The obstruction will cause problems such as reduction in flow, increased turbulence or pressures and blockages in the system, to name just a few. See Figure 310.5a for approved and prohibited installations that can cause a reduction in flow from fixtures and appliances.

APPROVED AND PROHIBITED INSTALLATIONS

An example of an approved fitting that intentionally creates an obstruction is a flow control device used on hydromechanical grease interceptors. The flow control is used to decrease flow at a designated amount for grease extraction. There shall be no solids in this effluent to cause a blockage when the flow control is used.

A four-inch by three-inch (100 mm by 80 mm) closet bend is not considered an obstruction in the direction of flow because the diameter of the outlet of the closet bowl normally varies between 2 3/8 inches and 2 3/4 inches. A 4-inch closet ring is normally used to secure the bowl to the closet bend. The purpose for using a four-inch diameter closet ring is for stability when securing both the water closet bowl and the closet ring to the floor. It is imperative that there is no contact between the water closet outlet (horn) and the closet ring or the closet bend inlet. This would create an obstruction and would continuously cause a blockage in the system.

To ensure no contact between the water closet horn and its closet ring or closet bend, the inlet opening on a closet bend is increased from 3 inches to 4 inches. The reduction in the diameter is in the vertical section of the pipe and does not cause an obstruction. It is also not necessary to maintain a four-inch diameter pipe to drain one water closet. The trap arm and drain may be 3 inches in size.

Offset closet flanges may obstruct flow if it does not comply with the applicable standard required by the UPC. For example, Table 701.2 requires PVC fittings to comply with ASTM D2665. In that standard, it references ASTM D3311, which is the standard for DWV plastic fittings patterns. The pattern for an offset closet flange must be free of ledges and corners that would obstruct flow (see Figure 310.5b).

OFFSET CLOSET FLANGES

From the 2024 UMC Illustrated Training Manual, Chapter 10, BOILERS AND PRESSURE VESSELS

1010.1 General. Where boilers are installed or replaced, clearance shall be provided to allow access for inspection, maintenance, and repair. Passageways around all sides of boilers shall have an unobstructed width of not less than 18 inches (457 mm). Clearance for repair and cleaning shall be permitted to be provided through a door or access panel into another area, provided the opening is of sufficient size.

Exception: Subject to the approval of the Authority Having Jurisdiction, boilers shall be permitted to be installed with a side clearance of less than 18 inches (457 mm), provided that the lesser clearance does not inhibit inspection, maintenance, or repair.

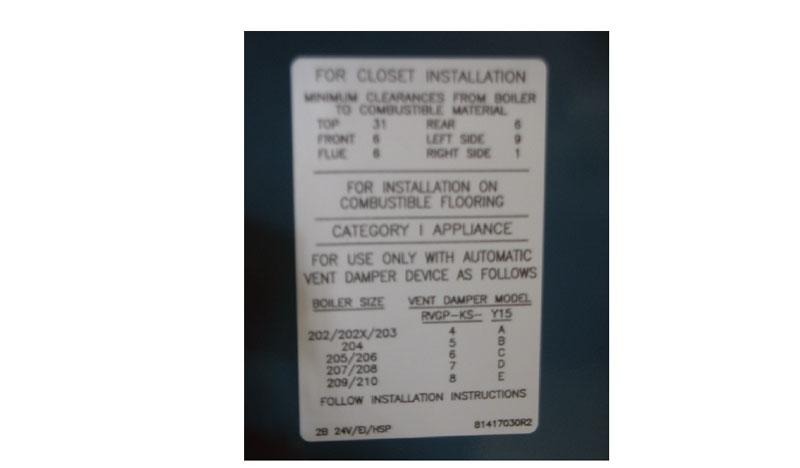

Boilers have a manufacturer’s listing plate, which will have the minimum clearances to combustibles and access (see Figure 1010.1). Check the listing plate and manufacturer’s installation instructions first, and then compare these clearances to the minimum clearances of the UMC.

There is an exception that allows the clearances to be reduced with prior approval by the Authority Having Jurisdiction (AHJ), provided that the lesser clearances do not inhibit inspection, maintenance and repair.

SAMPLE BOILER LISTING PLATE SHOWING MINIMUM CLEARANCES FROM BOILER TO COMBUSTIBLE MATERIALS

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: May 7, 2025