March 27, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 7, SANITARY DRAINAGE

715.3.1 Sewer Pipe Lining. For trenchless installation of resin-impregnated flexible tubing to line existing building sewers and building storm sewers installation shall be in accordance with ASTM F1216, ASTM F2561, ASTM F2599, or ASTM F3240.

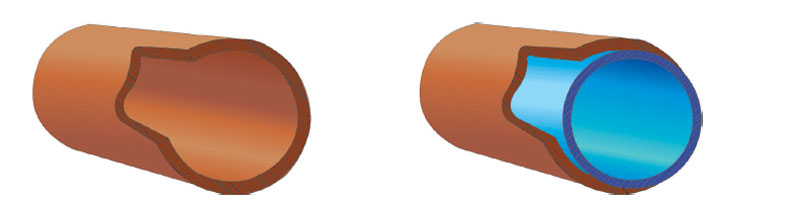

ASTM F1216 provides a detailed explanation of the cured in place pipe (CIPP) procedures. CIPP rehabilitation involves a linear insertion of a resin-saturated liner into the host pipe. The liner is either pulled or inverted through the host pipe. When inverted, the liner is turned inside-out as air is forced into one end of the liner. After the resin liner expands to the inside dimensions of the pipe, a curing process using heated water or steam polymerizes the resin liner to form a pipe within a pipe. This standard applies specifically to the installation of a resin-impregnated, flexible tube that is cured in place of the pipe (See Figure 715.3.1a). The standard provides installation requirements and inspection practices. Inspection requirements include cut samples for flexural and tensile testing, leakage testing, pressure pipe testing, delamination test, wall thickness, and a visual or closed-circuit television inspection. Trenchless methodology in accordance with ASTM F1216 is not allowed where the pipe is collapsed or compromised. This means that the cross-sectional area of the pipe is more than 40% obstructed preventing the insertion of the resinimpregnated tube.

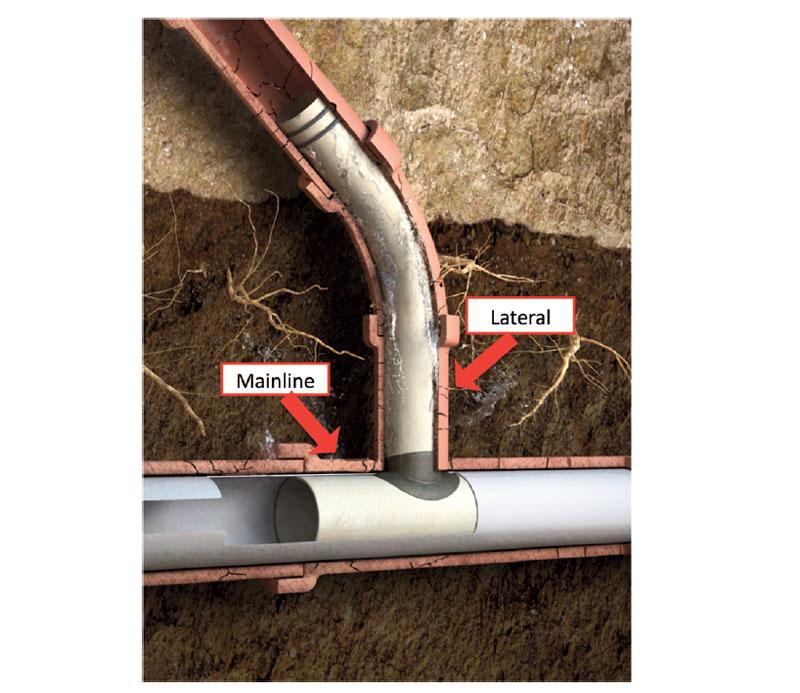

Reconstruction of a building sewer can also be accomplished using a sectional cured-in-place lining (SCIPL) in accordance with ASTM F2599, or a resin impregnated one piece main and lateral cured-in-place lining (MLCIPL) in accordance with ASTM F2561. The MLCIPL procedure connecting the lateral to the main uses seamless molded hydrophilic gaskets (SMHG) in accordance with ASTM F3240 (See Figure 715.3.1b). The MLCIPL system is limited to pipes having an inner diameter of 3 to 12 inches and its connection to the main pipe having an inner diameter of 6 to 24 inches with the building sewer limited to a maximum of 150 feet without excavation. The SCIPL system is limited to pipes having an inner diameter of 4 to 60 inches.

CURED IN PLACE PIPE

CURED-IN-PLACE LINING

Used with permission LMK Technology

From the 2024 UMC Illustrated Training Manual, Chapter 10, BOILERS AND PRESSURE VESSELS

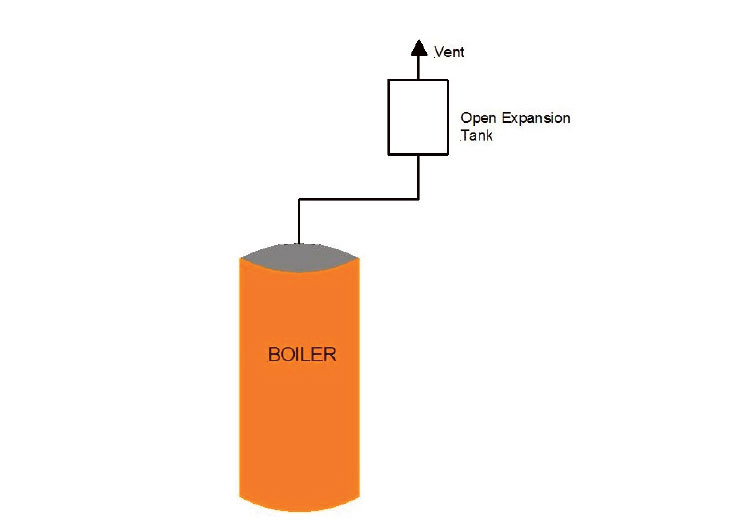

1004.2 Open-Type Expansion Tanks. Open type expansion tanks shall be located not less than 3 feet (914 mm) above the highest point of the system. Such tanks shall be sized based on the capacity of the system. An overflow with a diameter of not less than one-half the size of the supply or not less than 1 inch (25 mm) in diameter shall be installed at the top of the tank. The overflow shall discharge through an air gap into the drainage system.

With an open expansion tank, fresh air absorbed into the water tends to corrode the system. Open expansion tanks must be located at least three feet above the highest point of the system, sometimes on the top of buildings, where it may be exposed to freezing (see Figure 1004.2).

Open systems use a “feed and expansion” tank (cistern). As the name suggests, the tank is used to feed the supply and to accommodate any water expansion that is generated by the heating process. The “feed and expansion” tank is placed at the highest point in the system. An open-vented system typically uses a small-bore two pipe network, where one pipe is used to feed the system and the other allows the cooled water to return to the heat source (boiler).

(Courtesy of Praxis Green Inc.)

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: March 27, 2025