October 2, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 7 – SANITARY DRAINAGE

713.4 Public Sewer Availability. The public sewer shall be permitted to be considered as not being available where such public sewer or a building or an exterior drainage facility connected thereto is located more than 200 feet (60 960 mm) from a proposed building or exterior drainage facility on a lot or premises that abut and is served by such public sewer.

The installation of a private sewage disposal system is allowed when the public sewer is further than 200 feet of a building that is located on the lot that abuts the sewer.

713.5 Permit. No permit shall be issued for the installation, alteration, or repair of a private sewage disposal system, or part thereof, on a lot for which a connection with a public sewer is available.

If the public sewer is available when a permit to repair or replace a private sewage disposal system is requested, the permit will not be issued and the owner will have to connect to the public sewer. Section 713.7, Installation, makes an exception to this when there is insufficient depth for the owner to connect to the public sewer by gravity.

From the 2024 UMC Illustrated Training Manual, Chapter 6 – DUCT SYSTEMS

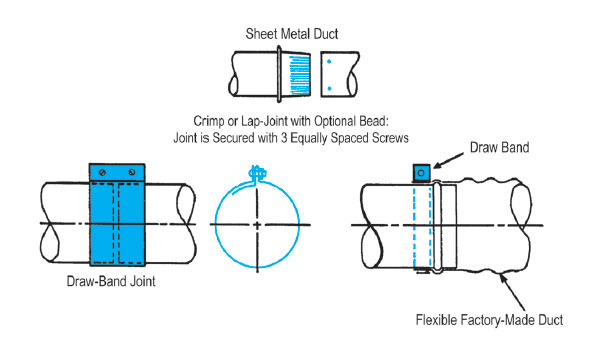

603.9 Joints and Seams of Ducts. Joints and seams for duct systems shall comply with SMACNA HVAC Duct Construction Standards – Metal and Flexible, SMACNA Round Industrial Duct Construction Standards, or SMACNA Rectangular Industrial Duct Construction Standards, as applicable. Joints of duct systems shall be made substantially airtight by means of tapes, mastics, gasketing, or other means. All ducts shall be sealed to Seal Class A. Crimp joints for round ducts shall have a contact lap of not less than 1 1/2 inches (38 mm) and shall be mechanically fastened by means of not less than three sheet-metal screws equally spaced around the joint, or an equivalent fastening method.

Air tightness is critical in duct systems to maintain overall energy and operating efficiency; therefore, the installer must make all joints “substantially airtight” with tapes, mastics, gasketing or other means. All transverse joints, longitudinal seams, and duct wall penetrations are to be sealed. Although allowable air loss is not defined, adequate airtightness can normally be ensured by sealing the ductwork properly. Also as noted in the SMACNA manual ‘Some sealants can adversely affect the release function of breakaway connections to fire dampers; consult the damper manufacturer for installation restrictions.’

RESIDENTIAL ROUND DUCT CONNECTIONS

Figure 603.9a illustrates acceptable methods for connecting residential round ducts.

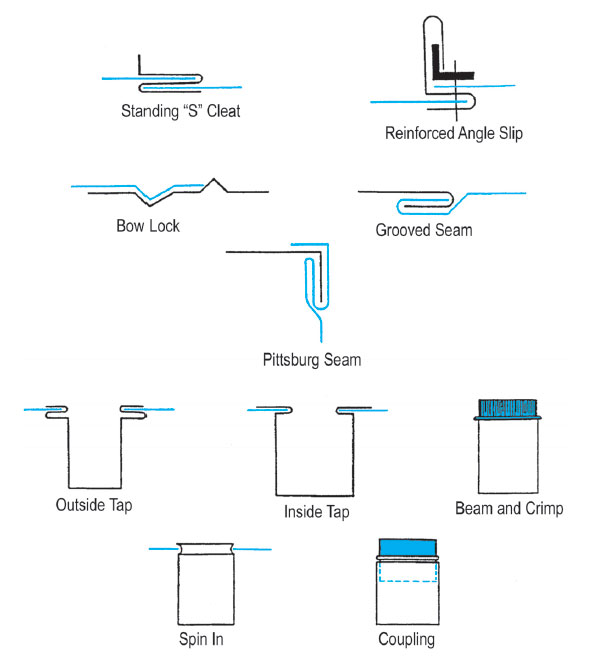

JOINTS AND CONNECTIONS

Figure 603.9b illustrates several other types of joints and seams.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: October 2, 2025