May 15, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 8, INDIRECT WASTES

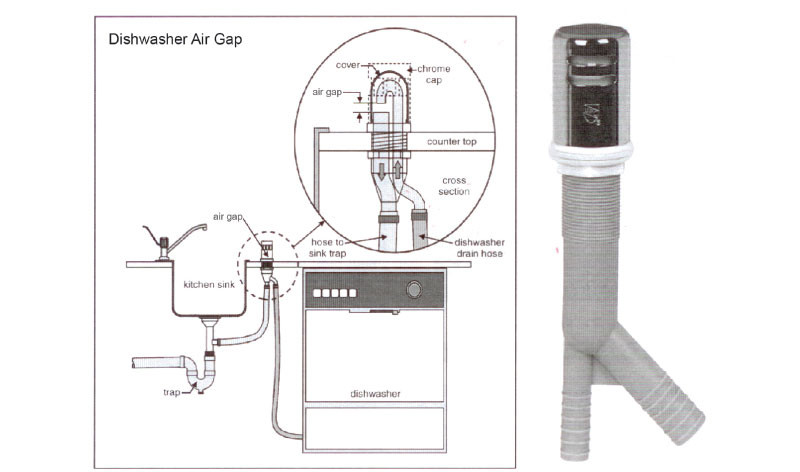

807.3 Domestic Dishwashing Machine. No domestic dishwashing machine shall be directly connected to a drainage system or food waste disposer without the use of an approved dishwasher air gap fitting on the discharge side of the dishwashing machine. Listed dishwasher air gap fittings shall be installed with the flood-level (FL) marking at or above the flood level of the sink or drainboard, whichever is higher.

ASSE 1021 and the IAPMO material and property standard PS 23 provide for approved listings for domestic dishwasher drain air gaps. Dishwasher drain air gaps are constructed to prevent the backflow of liquid waste when installed with the critical level at/or above the flood level rim of the fixture. The drain air gap will have the marking CL or c/l (ASSE 1021), or FL or F/L (IAPMO PS 23) located on the device to indicate the position of the dishwasher drain air gap in relation to the flood level of the receptacle (see Figures 807.3a and 807.3b).

DISHWASHER AIR GAP CONNECTION THROUGH DISPOSAL

DISHWASHER AIR GAP CONNECTION THROUGH SINK TAILPIECE AND AIR GAP FITTING

From the 2024 UMC Illustrated Training Manual, Chapter 13, FUEL GAS PIPING

1315.1.1 Longest Length Method. The pipe size of each section of gas piping shall be determined using the longest length of piping from the point of delivery to the most remote outlet and the load of the section. [NFPA 54:6.1.1]

The Longest Length Method requires only one distance measurement – the length from the meter to the most remote outlet. That measurement is then used to size the entire system. In all of the sizing tables the far left column is the “Length” column. For example, if there is a system with 137 feet of pipe from the meter to the most remote outlet and Table 1315.2(1) is being used, you would use the 150 foot row to size all pipe segments in the system.

This is a very simple method for sizing a fuel gas system and, for relatively small systems, it yields very similar sizes of pipe compared to using the Branch Length Method. However, if the system is a large installation, the use of the Branch Length Method could give smaller sizes in branch segments, and therefore, provide cost savings for the owner.

1315.1.2 Branch Length Method. Pipe shall be sized as follows:

(1) Pipe size of each section of the longest pipe run from the point of delivery to the most remote outlet shall be determined using the longest run of piping and the load of the section.

(2) The pipe size of each section of branch piping not previously sized shall be determined using the length of piping from the point of delivery to the most remote outlet in each branch and the load of the section. [NFPA 54:6.1.2]

The Branch Length Method also requires the distance of the pipe to be from the meter to the most remote outlet, but only for the purpose of sizing the system main. The piping from the remote outlet to the meter is also sized using the “Length” column in the sizing tables, but each branch off the main is measured from the meter to the furthest outlet on that branch. The piping from the remote outlet on that branch to the meter is then sized from that “Length” column.

For example, if there is a distance from the meter to the most remote outlet of 137 feet, the 150 foot length row in Table 1315.2(1) would be used again to size the system main. Next, each branch off of the main would have to be measured from the meter to the remote outlet on the branch, and then the piping from the remote outlet on the branch to the main would be sized. If there is a distance of 47 feet from the remote outlet on the branch to the meter, use the 50 foot row would be used to size the branch piping. Each branch would have to be sized in this manner.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: May 8, 2025