May 1, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 8, INDIRECT WASTES

801.3.2 Walk-In Coolers. For walk-in coolers, floor drains shall be permitted to be connected to a separate drainage line discharging into an outside receptor. The flood-level rim of the receptor shall be not less than 6 inches (152 mm) lower than the lowest floor drain. Such floor drains shall be trapped and individually vented. Cleanouts shall be provided at 90 degree (1.57 rad) turns and shall be accessibly located. Such waste shall discharge through an air gap or air break into a trapped and vented receptor, except that a full-size air gap is required where the indirect waste pipe is under vacuum.

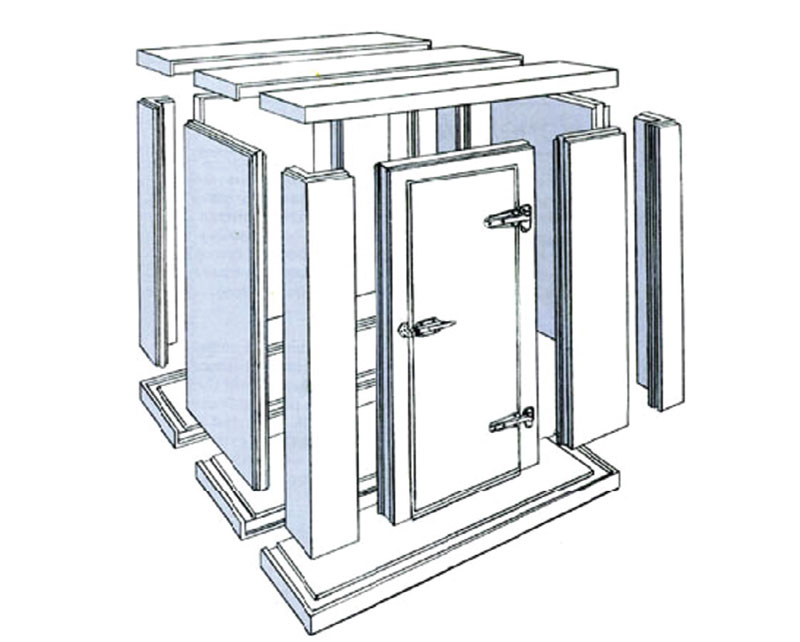

Walk-in coolers are usually erected separately inside the building structure. They are distinct room areas with walls, floors and ceilings designed to refrigerate its contents to a set temperature (see Figure 801.3.2a). The contents are most often food and beverage either in open or sealed containers. If the cooler is provided with floor drains, they cannot be directly connected to the drainage system.

FIGURE 801.3.2A

WALK-IN COOLER INSTALLATION

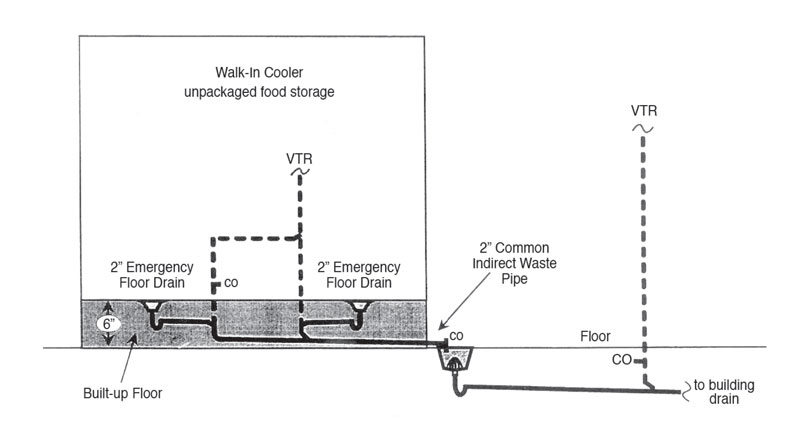

The possibility of contaminating the cooler contents in the event of the drainage system backing up, requires that the floor drains in the cooler indirectly discharge into a receptor through an air break or an air gap (an air gap is required under vacuum conditions). The drains shall be trapped and vented as normal, except they shall not connect with other vents of the drainage system (see Section 803.3). This is to prevent any contamination that may occur because of airflow between the drainage system and the cooler vents if the traps become dry (see Figure 801.3.2b). Indirect waste vents shall be permitted to connect with other indirect waste vents.

FIGURE 801.3.2B

WALK-IN COOLER FLOOR DRAIN PIPING

In this installation there is one other difference from a normal drainage system. This is the requirement for cleanouts at every 90-degree change in direction. The piping installation under a structure is not easily removed and its proximity to food or beverages requires more care than the normal situation; thus the need for more cleanouts to ensure any blockage can be removed.

One other consideration is the cooler’s operating temperature. If it is below freezing, the floor drain traps must be protected from freezing. This can usually be accomplished by applying heat tracing to the trap.

From the 2024 UMC Illustrated Training Manual, Chapter 13, FUEL GAS PIPING

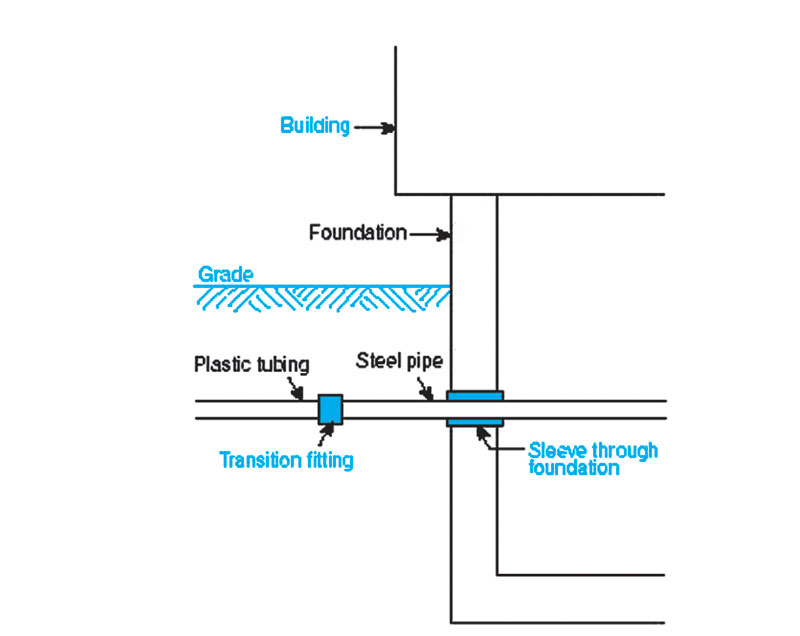

1310.1.5 Piping Through Foundation Wall. Piping through a foundation wall shall comply with all of the following:

(1) Underground piping, where installed through the outer foundation or basement wall of a building, shall be encased in a protective sleeve or protected by an approved device or method.

(2) The spaces between the gas piping and the sleeve and between the sleeve and the wall shall be sealed to prevent entry of gas and water.

(3) Sealing materials shall be compatible with the piping and sleeve. [NFPA 54:7.1.5]

If gas leaks in outdoor, underground piping it can migrate along the trench and into the basement instead of venting to the atmosphere above grade. This condition can be extremely hazardous. The requirement to seal the casing against water entry is in keeping with the desire to exercise good workmanship. See Figure 1310.1.5 for an illustration of a below-grade foundation wall penetration.

The use of an inert wrapping material provides an additional method of protection. The material must be of an approved type and be suitable for the application. The material must also be able to seal around the pipe and the wall to prevent the entry of gas or water.

PIPING THROUGH A FOUNDATION WALL

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: May 1, 2025