March 6, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 8, INDIRECT WASTES

801.3.1 Size of Indirect Waste Pipes. Except for refrigeration coils and ice-making machines, the size of the indirect waste pipe shall be not smaller than the drain on the unit, but shall be not smaller than 1 inch (25 mm), and the maximum developed length shall not exceed 15 feet (4572 mm). Indirect waste pipe for ice-making machines shall be not less than the drain on the unit and in no case less than 3/4 of an inch (20 mm).

Indirect waste piping shall be a minimum of one inch in size but not smaller than the drain of the equipment or fixture. For example, if a food preparation sink outlet is 1 1/2 inches, the indirect waste size would be a minimum of 1 1/2 inches. This indirect waste pipe would be limited in length to a maximum of 15 feet.

An exception to the length requirement is made for refrigeration coils and ice-making machines, which shall be a minimum of 3/4 of an inch in size but not smaller than the drain connection. There is no limitation on the length of the indirect waste piping from this type of equipment. The difference here is that the piping referred to is condensate or condensate overflow piping from the refrigeration unit that poses very little danger of contamination. This equipment is also usually placed in high areas or mounted on tall equipment, making it difficult to limit the piping to 15 feet as well as for any contamination to reach the coils or airflow of the equipment where it could spread the contamination.

From the 2024 UMC Illustrated Training Manual, Chapter 13, FUEL GAS PIPING

1308.4.4.2 Anodeless Risers. Anodeless risers shall comply with Section 1308.4.4.2.1 through Section 1308.4.4.2.3.

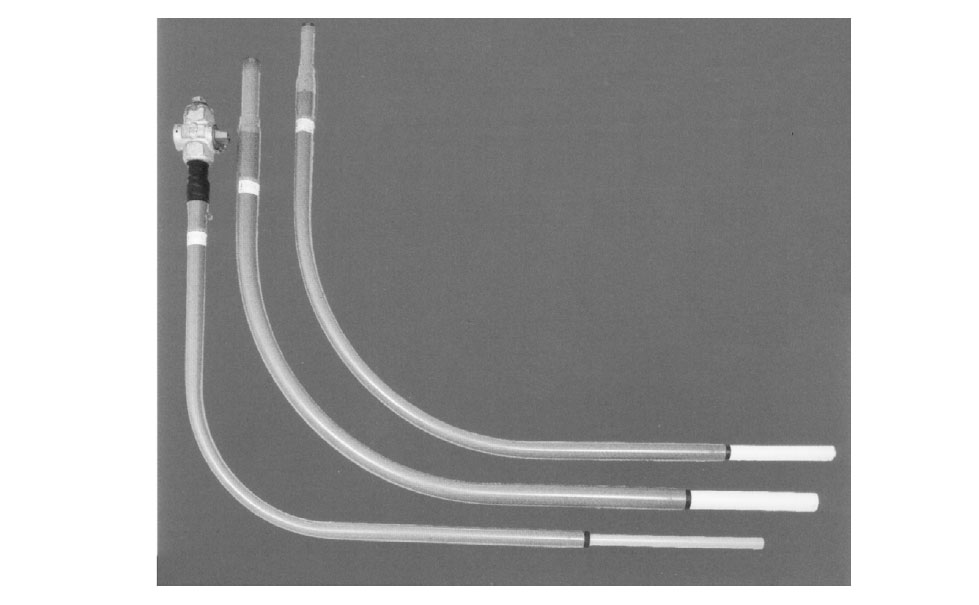

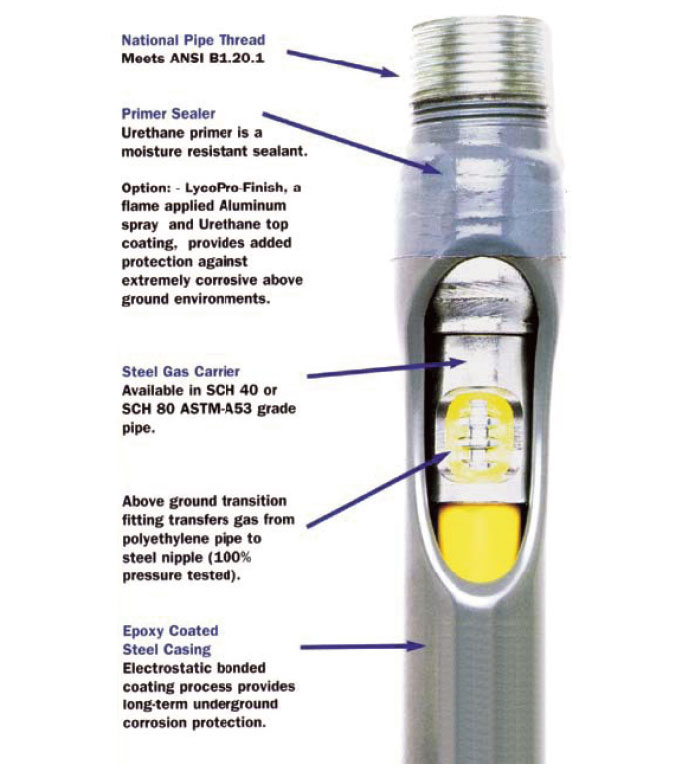

Anodeless risers are used to make the transition between underground PE pipe or tubing and metal pipe aboveground. As PE pipe must be installed below ground, risers are commonly used to connect the underground PE to aboveground piping materials. Anodeless risers are available as factory-assembled units and field-assembled kits. Anodeless risers are made from PE pipe inside a protective metal sheath, usually Schedule 40 steel pipe (see Figure 1308.4.4.2). The metal is protected from corrosion by a factory-applied coating and a separate anode is not required; hence the name “anodeless.” Factory-assembled risers usually have a 90-degree bend at the PE connection end and come in several lengths depending on the burial depth of the PE pipe.

ANODELESS RISERS

1308.4.4.2.1 Factory-Assembled Anodeless Risers. Factory-assembled anodeless risers shall be recommended by the manufacturer for the gas used and shall be leak-tested by the manufacturer in accordance with written procedures. [NFPA 54:5.5.4.3(1)]

1308.4.4.2.2 Service Head Adapters and Field-Assembled Anodeless Risers. Service head adapters and field assembled anodeless risers incorporating service head adapters shall be recommended by the manufacturer for the gas used and shall be design-certified to meet the requirements of Category I of ASTM D2513 and 49 CFR 192.281(e). The manufacturer shall provide the user qualified installation instructions as prescribed by 49 CFR 192.283(b). [NFPA 54:5.5.4.3(2)]

See Figure 1308.4.4.2.2.

ANODELESS RISER

1308.4.4.2.3 Undiluted Liquefied Petroleum Gas Piping. The use of plastic pipe, tubing, and fittings in undiluted LP-Gas piping systems shall be in accordance with NFPA 58. [NFPA 54:5.5.4.3(3)]

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: March 6, 2025