March 20, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 6, WATER SUPPLY AND DISTRIBUTION

609.9 Low-Pressure Cutoff Required on Booster Pumps for Water Distribution Systems. Where a booster pump (excluding a fire pump) is connected to a building supply or underground water pipe, a low-pressure cutoff switch on the inlet side of the pump shall be installed not more than 5 feet (1524 mm) of the inlet. The cutoff switch shall be set for not less than 10 psi (69 kPa). A pressure gauge shall be installed between the shutoff valve and the pump.

The low pressure cutoff is required because of the possibility of an excessive pressure drop resulting in negative pressure on the suction side (inlet) of the pump creating a phenomenon called cavitation. When cavitation occurs, cavities or voids form in the pump creating turbulence that causes damage to the impellers and eventually to pump failure. This failure could also lead to backflow contamination.

From the 2024 UMC Illustrated Training Manual, Chapter 5, EXHAUST SYSTEMS

506.5 Fittings. Fittings in Class 2, 3, and 4 systems shall be not less than two gauges thicker than the thickness required for straight runs. Flexible metallic duct shall be permitted to be used for connecting ductwork to vibrating equipment. Duct systems subject to wide temperature fluctuations shall be provided with expansion joints.

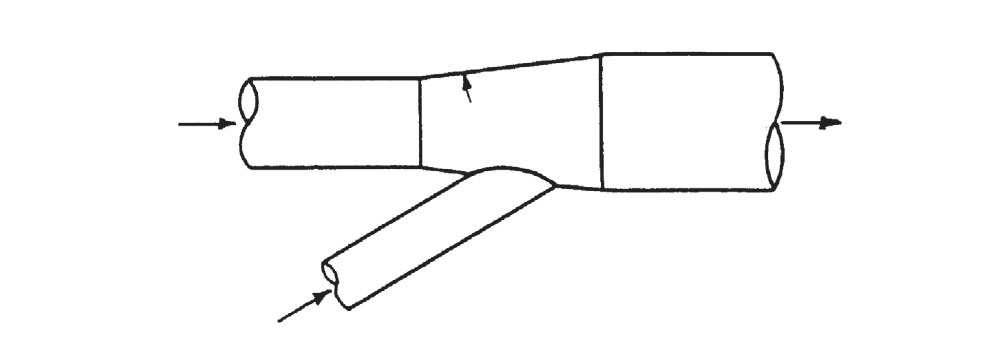

Branches shall connect to main ducts at the large end of transitions at an angle not exceeding 45 degrees (0.79 rad).

Except for ducts used to convey noncorrosive vapors with no particulate, accessible cleanouts shall be provided at 10 foot (3048 mm) intervals and at changes in direction. Access openings shall also be provided for access to sprinklers and other equipment within the duct that require servicing.

In Class 2, 3 and 4 duct systems, the fittings must be not less than two gauges thicker than the thickness required for straight runs. The increase in turbulence experienced at fittings could cause a greater friction within the fitting.

Expansion joints are required when wide temperature variations are encountered in a product-conveying duct system, such as one carrying heated gases.

Duct branches must connect to main ducts (or plenums) at the large end of the transitions at an angle not exceeding 45 degrees. The purpose is to avoid excessive turbulence and possible deposits of the material being conveyed on duct interior surfaces (see Figure 506.5).

DUCT BRANCH

Accessible cleanouts are required at 10-foot intervals for product-conveying ducts, except for those conveying noncorrosive vapors with no particulates. Access openings are also required to fire sprinklers and to other equipment requiring servicing within the duct. The size of the opening should be adequate in size to facilitate equipment used for cleaning.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: March 20, 2025