June 6, 2024

From the 2024 UPC Illustrated Training Manual, Chapter Chapter 8, INDIRECT WASTES

807.1 Non-Classed Apparatus. Commercial dishwashing machines, silverware washing machines, and other appliances, devices, equipment, or other apparatus not regularly classed as plumbing fixtures, which are equipped with pumps, drips, or drainage outlets, shall be permitted to be drained by indirect waste pipes discharging through an air break into an approved type of open receptor.

It is common for health departments to require indirect connections for commercial dishwashing and silverware washing machines. An indirect connection, when properly maintained, will prevent sewage backup into the machines, whereas a direct connection will allow backup into these machines.

Other appliances may require indirect wastes and there is more than one method to dispose of that waste. One method of discharging undiluted condensate by indirect waste is included in Sections 807.2. The user of this Code should consult the AHJ prior to installing commercial appliances to determine whether a direct or indirect connection is required on a specific appliance.

From the 2024 UMC Illustrated Training Manual, Chapter Chapter 5, EXHAUST SYSTEMS

510.5.3.2 Welded Duct Connection. Acceptable duct-to-duct connection shall be as follows:

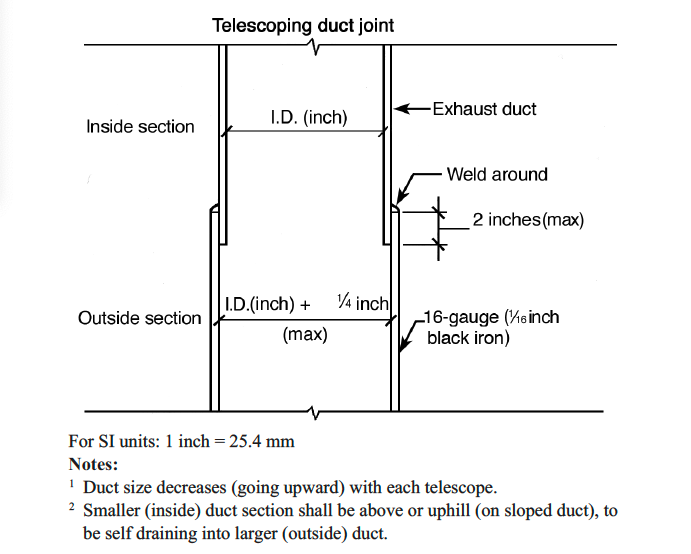

(1) Telescoping joint, as shown in Figure 510.5.3.2(1).

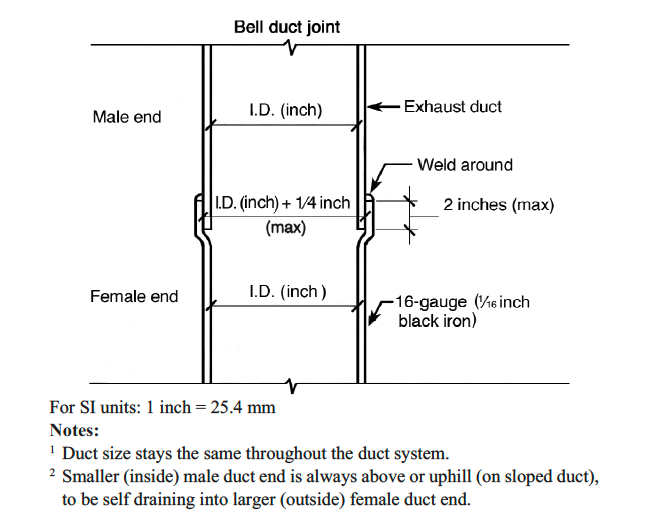

(2) Bell-type joint, as shown in Figure 510.5.3.2(2).

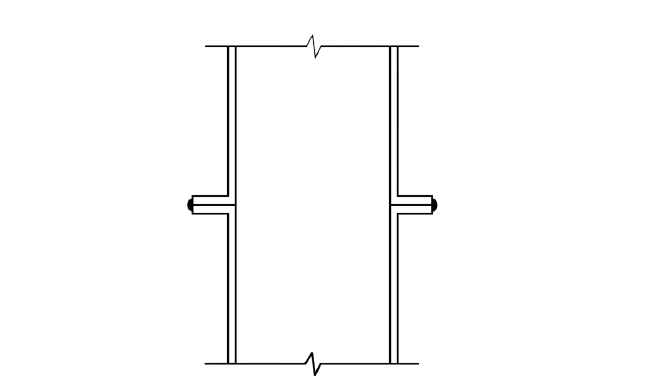

(3) Flange with edge weld, as shown in Figure 510.5.3.2(3).

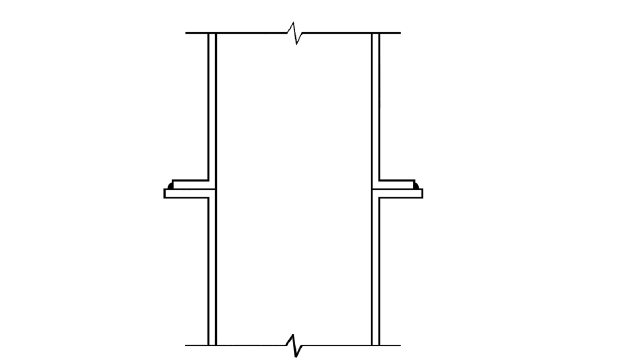

(4) Flange with lap joint weld, as shown in Figure 510.5.3.2(4). [NFPA 96:7.5.5.1]

TELESCOPING -TYPE DUCT CONNECTION

[NFPA 96: FIGURE 7.5.5.1(a)]

BELL-TYPE DUCT CONNECTION

[NFPA 96: FIGURE 7.5.5.1(b)]

FLANGE WITH EDGE WELD DUCT CONNECTION

[NFPA 96: FIGURE 7.5.5.1(c)]

FLANGE WITH LAP JOINT WELD DUCT CONNECTION

[NFPA 96: FIGURE 7.5.5.1(d)]

Overlapping ducts minimize leakage due to failed weld. In most instances, welds in the shop are done under more ideal conditions where the welder can turn the duct for access for proper weld penetration. Clearances on the job site with the duct in place make a proper weld more difficult to perform. Limiting the overlap to 2 inches maximum decreases the possibility that excessive gaps in the duct could develop during the welding process. Although not included in the text here, NFPA 96: 7.5.5.1 (3) and (4) call a flange weld an acceptable duct-to-duct connection [see Figures 510.5.3.2(1) through 510.5.3.2(4)]. Horizontal ducting (with flange welds) is particularly susceptible to pocketing grease and leaking where the welds are not completely liquid tight.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: June 6, 2024