June 13, 2024

From the 2024 UPC Illustrated Training Manual, Chapter Chapter 10, TRAPS AND INTERCEPTORS

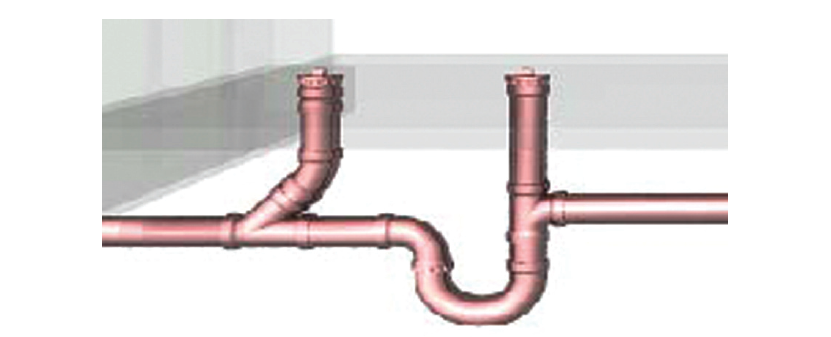

1008.0 Building Traps.

1008.1 General. Building traps shall not be installed except where required by the Authority Having Jurisdiction. Each building trap where installed shall be provided with a cleanout and with a relieving vent or freshair intake on the inlet side of the trap, which needs not be larger than one-half the diameter of the drain to which it connects. Such relieving vent or fresh-air intake shall be carried above grade and terminate in a screened outlet located outside the building.

ONE TYPE OF BUILDING TRAP

Building traps (see Figure 901.2f) are generally not installed although there may be reasons for their inclusion in the building sewer. Therefore the code allows the AHJ to make the determination when they are necessary. Some of the reasons for prohibiting building traps are:

1) it interferes with the flow of sewage and air movements in the plumbing system;

2) it reduces the carrying capacity of the building drain due to the added resistance;

3) it increases the potential of back pressure in the soil stack; and

4) it reduces the ventilation of the street sewers.

Some of the reasons for permitting the use of building traps are:

1) it affords an additional barrier against admission of sewer gas in case of trap evaporation or leakage;

2) it is needed in very cold climates to prevent frost closure of a vent terminal by reducing the circulation of air communicated from the street sewer through the plumbing system;

3) it prevents exposing neighboring occupants to foul odors communicated through a vent terminal where buildings are in close proximity to each other.

The building trap is also used where there is a combined sewer and storm system (see Section 1101.15). Sewer gas is not permitted into the storm drainage system by the use of a building trap installed on the main storm drain before the wye connection to the combined building sewer. The Code does not require a fresh air inlet for a building storm drain trap, but a cleanout has to be provided on the outlet side of the trap.

From the 2024 UMC Illustrated Training Manual, Chapter 9 – INSTALLATION OF SPECIFIC APPLIANCES

902.1 Nonindustrial Appliances. This chapter is applicable primarily to nonindustrial-type appliances and installations and, unless specifically indicated, does not apply to industrial-type appliances and installations. Listed appliances shall be installed in accordance with their listing and the manufacturer’s installation instructions or, as elsewhere specified in this chapter, as applicable to the appliance. Unlisted appliances shall be installed as specified in this part as applicable to the appliances.

All listed gas-fired equipment and accessories shall be installed according to the listing and the manufacturers’ instructions. Code requirements for unlisted equipment installations are specified throughout this chapter.

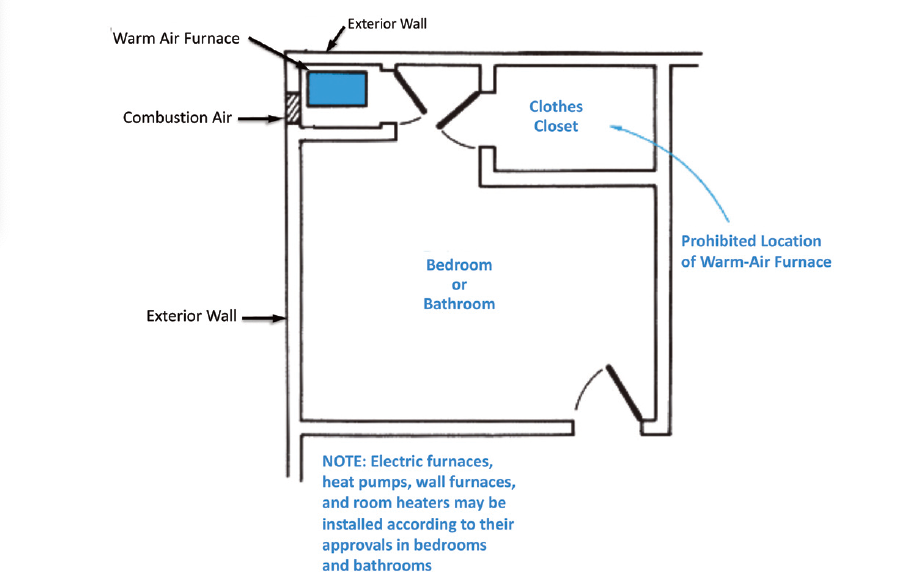

If a gas appliance, other than a direct-vent type, is installed in a sleeping room or bathroom where combustion, ventilation, and dilution are obtained from the same space, refer to Chapter 7, Section 701.4, Indoor Combustion Air. When calculating combustion air, the minimum volume of indoor air required is 50 cubic feet per 1,000 Btu/hr. It is important to note that many variables affect the efficient operation of a gas-fired appliance that vents hazardous byproducts of combustion to the atmosphere. Such variables include, but are not limited to, type of appliance and venting requirements, air exchanges per hour (ACH), air infiltration, and return air locations. To ensure proper ventilation, all code requirements and life/safety issues are to be considered before installing an appliance in a sleeping room or bathroom (see Figure 902.1).

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: June 13, 2024