July 31, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 9, VENTS

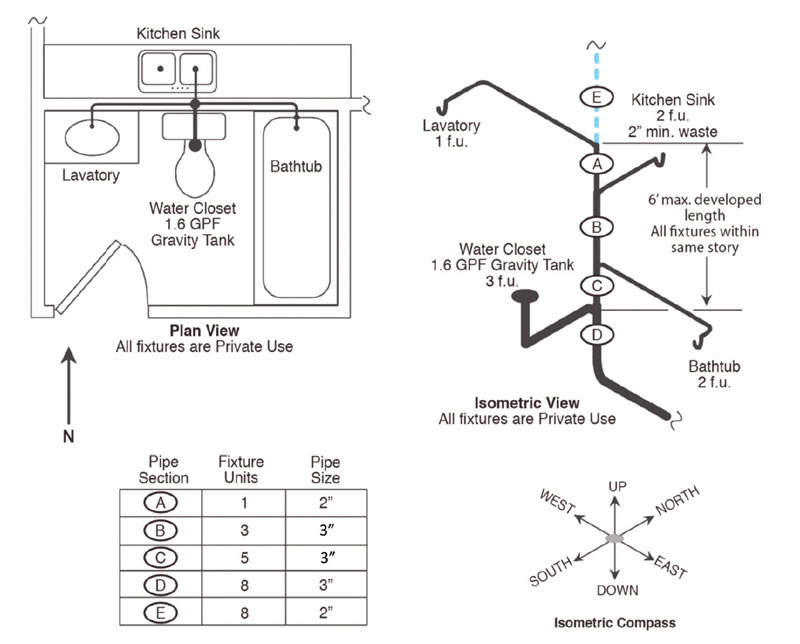

908.1 Vertical Wet Venting. Wet venting is limited to vertical drainage piping receiving the discharge from the trap arm of one and two fixture unit fixtures that also serves as a vent not exceeding four fixtures. Wet-vented fixtures shall be within the same story; provided, further, that fixtures with a continuous vent discharging into a wet vent shall be within the same story as the wet-vented fixtures. No wet vent shall exceed 6 feet (1829 mm) in developed length.

The vertical wet vent is a vertical drain that acts as a vent for the trap arms located below it. Hence, a wetted vent (see Figure 908.1a where pipe sections A, B and C is the vertical wet vented portion). It serves two purposes; one as a drain and one as a vent. This fact is very important. In the vertical wet vent only trap arms are connected to the wet vent, not waste branches. This effectively limits the connection to the wet vent section to single fixture connections.

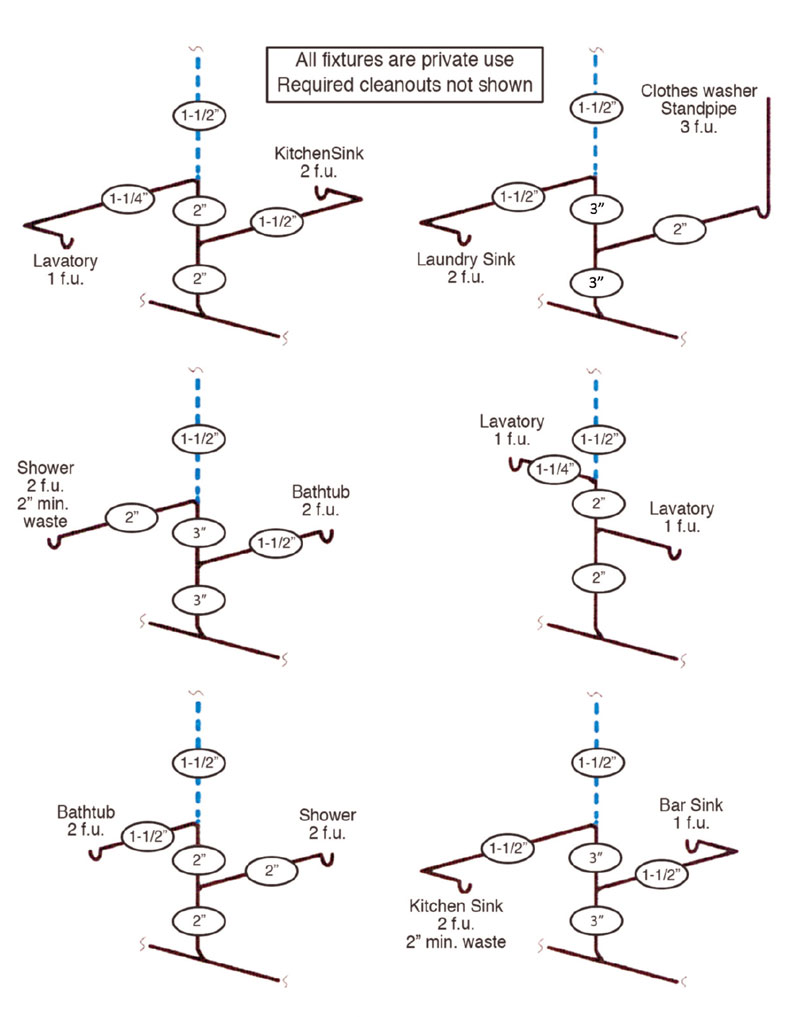

Fixture trap arm connections discharging into the vertical wet vent are limited to one and two drainage fixtures units. This limits the type of fixtures that can discharge into the vertical wet vent. For example, no water closet or clothes washer may discharge into the vertical wet vent because of the large volume of water discharge and high flow rates that could siphon the other fixture traps. However, the toilet and clothes washer may be vented by the vertical wet vent (see Figures 908.1a and 908.1b).

The vertical wet vent cannot serve more than four fixtures. In application, the maximum drainage fixture units served by any vertical wet vent will be equal to four sets of two drainage fixtures units, for a total of eight DFUs. This will effectively limit the size of the wet vent. The minimum size for the wet vent is two inches, and eight DFUs require a minimum two-inch waste.

Fixtures that connect to the vertical wet vent must be on the same floor as well as the fixture serving as the wet vent. In other words, the fixture serving as the vertical wet vent is the uppermost fixture with the continuous vent. This uppermost fixture may not be on an upper floor level wet venting fixtures on the lower level.

WET VENT SIZING EXAMPLE 2

WET VENT SIZING EXAMPLE 1

From the 2024 UMC Illustrated Training Manual, Chapter 6, DUCT SYSTEMS

603.4 Flexible Air Ducts. Flexible air ducts shall comply with UL 181, and shall be installed in accordance with the manufacturer’s installation instructions and SMACNA HVAC Duct Construction Standards – Metal and Flexible. Flexible air duct installations shall comply with the following:

(1) Ducts shall be installed using the minimum required length to make the connection.

(2) Horizontal duct runs shall be supported at not more than 4 feet (1219 mm) intervals.

(3) Vertical risers shall be supported at not more than 6 feet (1829 mm) intervals.

(4) Sag between support hangers shall not exceed 1/2 inch (12.7 mm) per foot (305 mm) of support spacing.

(5) Supports shall be rigid and shall be not less than 1 1/2 inches (38 mm) wide at point of contact with the duct surface.

(6) Duct bends shall be not less than one duct diameter bend radius.

(7) Screws shall not penetrate the inner liner of non-metallic flexible ducts unless permitted in accordance with the manufacturer’s installation instructions.

(8) Fittings for attaching non-metallic ducts shall be beaded and have a collar length of not less than 2 inches (51 mm) for attaching the duct. Metal worm-gear clamps shall be used.

Exception: Where attaching metallic ducts using screws in accordance with the manufacturer’s installation instructions.

(9) Duct inner liner shall be installed at not less than 1 inch (25.4 mm) on the collar and past the bead prior to the application of the tape and mechanical fastener. Where mastic is used instead of tape, the mastic shall be applied in accordance the mastic manufacturer’s instructions.

(10) Duct outer vapor barriers shall be secured using two wraps of approved tape. A mechanical fastener shall be permitted to be used in place of, or in combination with, the tape.

(11) Flexible air ducts shall not penetrate a fire-resistance rated assembly or construction.

(12) The temperature of the air to be conveyed in a flexible air duct shall not exceed 250°F (121°C).

(13) Flexible air ducts shall be sealed in accordance with Section 603.9.

The user of the UMC is to be aware that SMACNA is an installation standard and UL 181 is a material standard. Both standards would need to be referenced to ensure compliance with the UMC. Many HVAC installations utilize flexible air ducts and connectors, and the UMC provides specific requirements for flexible air ducts and connectors that can be used by designers for factory-made air ducts. Flexible air ducts are considered factory-made air ducts. Unlike flexible air ducts and connectors, not all factory-made air ducts are required to comply with UL 181. UL 181 addresses requirements which include preformed lengths of flexible or rigid ducts, materials in the form of boards for field fabrication of lengths of rigid ducts, and preformed flexible air connectors. The user is to refer to the manufacturer’s installation instructions and SMACNA for the installation of flexible air ducts since both sources will provide installation instructions for flexible air ducts and connectors. The temperature limitation is the industry standard for warm air. The material in flexible air ducts and air connectors are only tested to resist a temperature up to 250°F (121°C).

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: July 31, 2025