July 24, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 9, VENTS

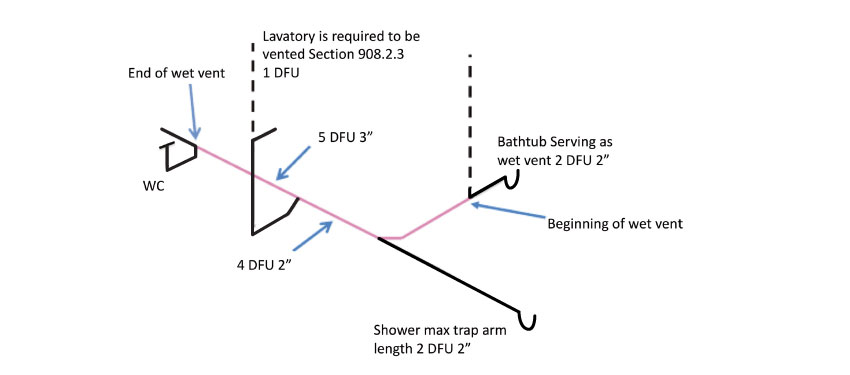

908.2.3 Trap Arm. The length of the trap arm shall not exceed the limits in Table 1002.2. The trap size shall be in accordance with Section 1003.3. The vent pipe opening from the horizontal wet vent, except for water closets and similar fixtures, shall not be below the weir of the trap.

The last sentence prohibiting the vent pipe opening below the weir of the trap, would not allow an unvented lavatory to connect independently to the wet vented horizontal branch even though the distance of the lavatory trap arm to the wet vented horizontal branch is in accordance with Table 1002.2. An unvented lavatory trap arm would form an S-trap, which is in conflict with Section 1004.1 that prohibits S-traps. With this provision, the lavatory(s) may serve as the wet vent, or shall be individually vented when not serving as the wet vent (as shown in Figure 908.2.3).

LAVATORY REQUIRING AN INDIVIDUAL VENT

From the 2024 UMC Illustrated Training Manual, Chapter 13, FUEL GAS PIPING

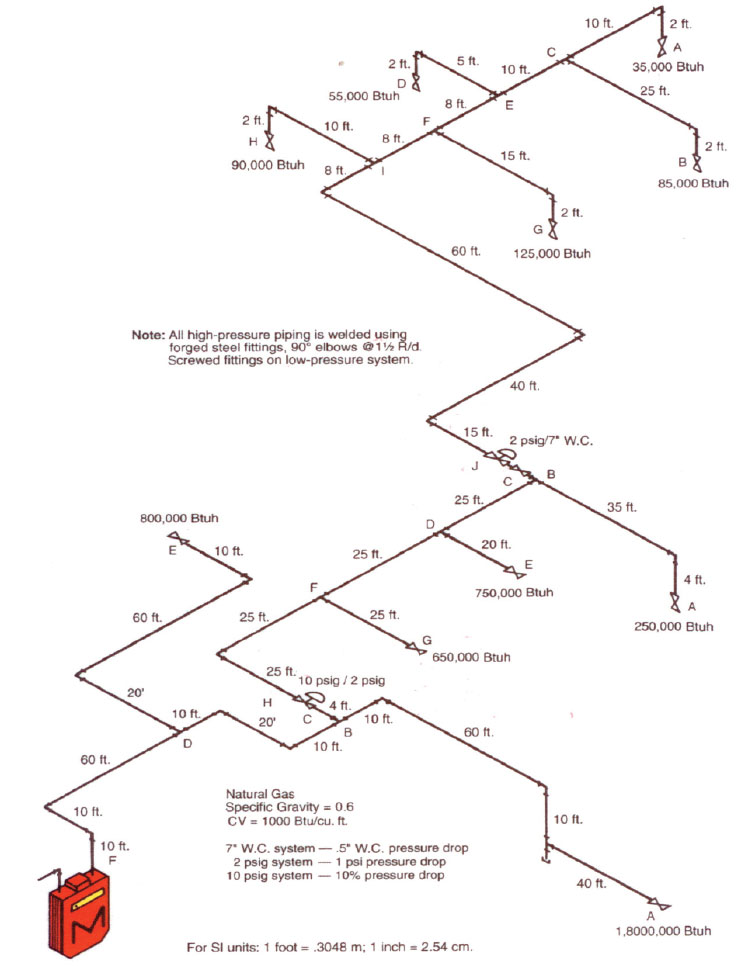

1315.1.3 Hybrid Pressure. The pipe size for each section of higher pressure gas piping shall be determined using the longest length of piping from the point of delivery to the most remote line pressure regulator. The pipe size from the line pressure regulator to each outlet shall be determined using the length of piping from the regulator to the most remote outlet served by the regulator. [NFPA 54:6.1.3]

Large systems are sometimes designed to have a higher pressure than the normal fuel-gas system. This inlet pressure is the pressure at the meter outlet, which is also the piping inlet. Using a higher inlet pressure will allow smaller main and branch pipe sizes. However, most appliances require a pressure regulator to bring the pressure down to the working pressure of the appliance. A system with regulators at each appliance could be a “medium” or “high-pressure” system, depending on the pressure of the gas. Sizing would be accomplished using only one sizing table.

The Hybrid Pressure Method is used to size fuel-gas systems utilizing two or more different inlet pressure values. A hybrid pressure system is one that would require a line pressure regulator to step the higher main line pressure to a lower pressure, which is usually the appliance working pressure. In this design, only one line regulator is needed rather than several appliance regulators, as in a high-pressure system. Two sizing tables will have to be used to size the system – one to size the higher pressure portion of the system and another to size the reduced pressure portion of the system. Either sizing method, Branch or Longest Length, could be used in sizing the hybrid system. Figure 1315.1.3 illustrates a complicated hybrid pressure gas system.

HYBRID PRESSURE GAS SYSTEM

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: July 24, 2025