July 10, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 12, FUEL GAS PIPING

1211.2 Bonding of CSST Gas Piping. CSST gas piping systems, and gas piping systems containing one or more segments of CSST, shall be electrically continuous and bonded to the electrical service grounding electrode system or, where provided, lightning protection grounding electrode system. [NFPA 54:7.12.2]

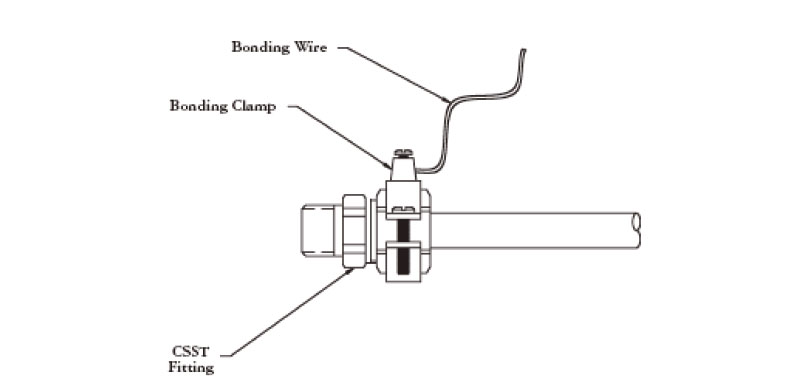

CSST systems are required by the manufacturer to be electrically bonded (see Figure 1211.2a).

ELECTRICAL BONDING OF CSST SYSTEM

Grounding vs Bonding

Grounding is a type of bonding, in which the conductive objects are connected to the earth using a conductor or metallic rod. The connection between an electrical circuit or instrument and the earth is known as Grounding. Grounding, sometimes called Earthing, ensures that all metal parts of an electrical circuit that an individual might contact are connected to the earth, thus ensuring zero voltage.

Bonding, by definition, is the joining of metallic pieces to form a conducting path which ensures safe electrical continuity. Bonding is generally done as protection from electrical shocks. Two or more conductive objects are required for a bonding connection, which is accomplished by connecting the metallic pieces together by means of a conductor (wire). Bonding provides the safety in the case of fault current. In the case of CSST (corrugated stainless steel tubing) used in fuel gas piping, bonding may reduce the risk of damage and fire from lighting strike by reducing the risk of arcing. According to the National Electrical Code (NEC), gas piping systems are considered to be direct-bonded if connected to the electrical service equipment enclosure, the grounded conductor at the electrical service, the grounding electrode conductor or one of more of the grounding electrodes used.

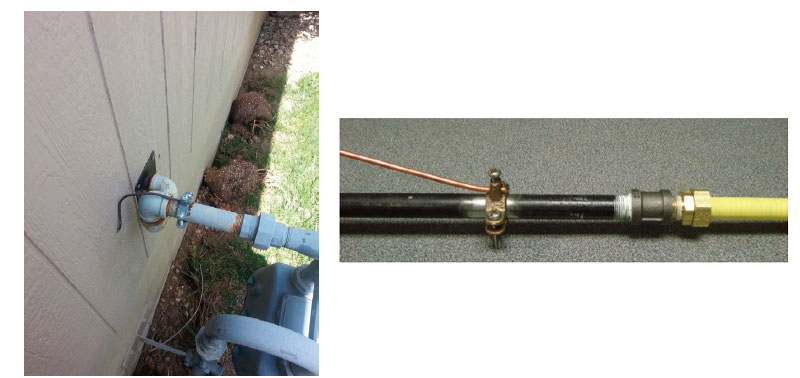

A common bonding installation for single or multi-family structures would be a single connection on the steel nipple downstream of the gas meter and prior to the first CSST connection (see Figure 1211.2b). The conductor should be no smaller than a 6 AWG copper wire and should be attached in accordance with the requirements found in the NEC. Bonding clamps shall be installed in accordance with their listings per UL 467 and need to make metal-to-metal contact with a steel pipe component or the first CSST fitting (see Figure 1211.2c).

Right: FIGURE 1211.2C BONDING CLAMP AND CONDUCTOR

From the 2024 UMC Illustrated Training Manual, Chapter 13, FUEL GAS PIPING

1310.11.1.1 Shutoff Valves for Multiple House Lines. In multiple-tenant buildings supplied through a master meter, through one service regulator where a meter is not provided, or where meters or service regulators are not readily accessible from the appliance or equipment location, an individual shutoff valve for each apartment or tenant line shall be provided at a convenient point of general accessibility. In a common system serving a number of individual buildings, shutoff valves shall be installed at each building. [NFPA 54:7.8.3.1]

The reason for requiring a shutoff valve for each line is to allow for the system to be separated for repair or maintenance (see Figure 1310.11.1.1). In a case where only part of the system has to be shut down for repair, the remaining system can continue to operate. Shutoff valves must be plainly marked and accessible so that service persons can determine which lines service which units or buildings.

MANUAL GAS SHUTOFF VALVE

The requirement of a shutoff valve for each building provides emergency responders with the ability to shut off the flow of gas to a building involved in a fire. In natural gas installations, this shutoff valve is part of the utilities service and meter installation. The natural gas supplier provides a shutoff valve for the supply to its gas meter under the U.S. Department of Transportation regulations (49 CFR 192).

The installations just described are presumed to be obvious enough to meet the requirement of being “plainly marked.” The requirement of posting the location is not treated uniformly by different gas suppliers and local fire departments. Where an installation is not obvious (e.g., an underground propane tank or a meter/regulator concealed by vegetation), a sign or other marking may be needed or required by the AHJ. The intent of this provision is to enable emergency responders to shut off the gas supply to a building in the event of a fire. The local fire department is normally the AHJ for this requirement.

In LP-gas systems, the emergency shutoff valve is normally the propane tank shutoff valve.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: July 10, 2025