January 9, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 6 – WATER SUPPLY AND DISTRIBUTION

606.0 Valves.

606.1 General. Valves up to and including 2 inches (50 mm) in size shall be copper alloy or other approved material. Sizes exceeding 2 inches (50 mm) shall be permitted to have bodies of cast iron, copper alloy, or other approved materials. Each gate or ball valve shall be a fullway or fullport type with working parts of the non-corrosive material. Where valves are made from copper alloys containing more than 15 percent zinc by weight and are used in plastic piping systems, they shall be resistant to dezincification and stress corrosion cracking in compliance with NSF/ANSI 14. Valves carrying water used in potable water systems shall comply with the requirements of ASME A112.4.14/CSA B124.14, ASME B16.34, ASTM F1970, ASTM F2389, AWWA C500, AWWA C504, AWWA C507, IAPMO/ANSI Z1157, MSS SP-67, MSS SP-70, MSS SP-71, MSS SP-72, MSS SP-78, MSS SP-80, MSS SP-110, MSS SP-122, or NSF/ANSI 359. Valves intended to supply drinking water shall also comply with the requirements of NSF/ANSI/CAN 61.

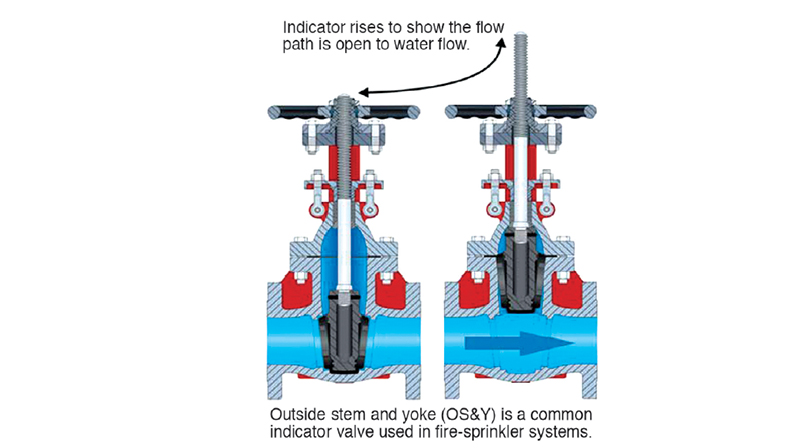

Fullway gate (or ball) valves are intended to be fully opened or fully closed when in service and are for the sole purpose of providing isolation of a complete piping system or isolation of an individual zone within a system. These valves are not designed or intended to be utilized for regulation or modulation of water flow. Conversely, globe valves (regulating valves) are not designed or intended to be utilized as “control” valves. As applied in Section 606.0, the word “control” means to “check or restrain” the flow of water; consequently, fullway valves are designed to always be in one of two possible positions––full restraint or no restraint. These two operating positions (full open or full closed) are consistent with the listing standards for gate valves and with the manufacturer’s recommended operating instructions (see Figure 606.1).

Gate valves should never be left partially open or partially closed. A valve gate that extends into the water stream will lose material through the process of erosion and, eventually, will be useless as a means of stopping water flow.

ONE TYPE OF FULLWAY VALVE

From the 2024 UMC Illustrated Training Manual, Chapter 10, BOILERS AND PRESSURE VESSELS

1005.5 Vacuum Relief Valve. Hot-water heating systems that are subjected to a vacuum while in operation or during shutdown shall be protected with a vacuum relief valve that complies with ANSI Z21.22/CSA 4.4. Where the piping configuration, equipment location, and valve outlets are located below the boiler elevation, the system shall be equipped with a vacuum relief valve at the highest point.

Vacuum relief valves should be installed in hotwater systems that are subjected to a vacuum. Vacuum relief valves are required to facilitate full draining of the system during shutdown and servicing.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: January 9, 2025