January 29, 2026

From the 2024 UPC Illustrated Training Manual, Chapter 5, WATER HEATERS

510.2.21 Vent Connector Sizing. Vent connectors shall not be increased more than two sizes greater than the listed appliance categorized vent diameter, flue collar diameter, or draft hood outlet diameter. Vent connectors for draft hood equipped appliances shall not be smaller than the draft hood outlet diameter. Where a vent connector size(s) determined from the tables for a fan-assisted appliance(s) is smaller than the flue collar diameter, the use of the smaller size(s) shall be permitted, provided that the installation complies with all of the following conditions:

(1) Vent connectors for fan-assisted appliance flue collars 12 inches (300 mm) in diameter or smaller are not reduced by more than one table size [e.g., 12 inches to 10 inches (300 mm to 250 mm) is a one-size reduction], and those larger than 12 inches (300 mm) in diameter are not reduced more than two table sizes [e.g., 24 inches to 20 inches (600 mm to 500 mm) is a two-size reduction].

(2) The fan-assisted appliance(s) is common vented with a draft hood-equipped appliance(s).

(3) The vent connector has a smooth interior wall. [NFPA 54:13.2.24]

A sudden, large expansion of the vent connector diameter creates a pressure drop that may limit the draft and encourage condensation. Therefore, this section places a limit on upsizing, limiting the vent connector diameter to two sizes larger than one of the following, whichever is applicable:

- Appliance-categorized vent connector diameter;

- Flue collar diameter; or

- Draft hood outlet diameter.

Note that an appliance includes either a draft hood or flue collar for connection to the vent or vent connector. The term “appliance-categorized vent diameter/area” is defined as follows:

The minimum vent area/diameter permissible for Category I appliances to maintain a nonpositive vent static pressure when tested in accordance with nationally recognized standards.

Therefore, where connecting an appliance to a vent connector, use the applicable tables in Section 510.0 to find the minimum size vent connector. Note that only smooth wall vent connectors may be downsized. It would also be advisable to check with the manufacturer to make sure it allows a downsizing.

From the 2024 UMC Illustrated Training Manual, Chapter 12, HYDRONICS

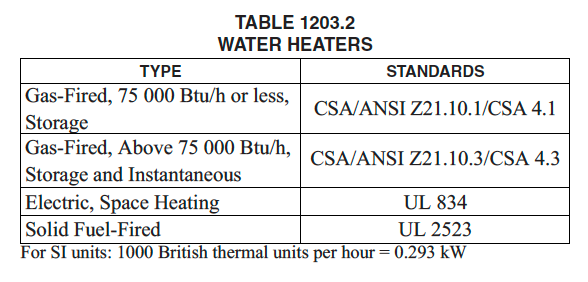

1203.2 Dual Purpose Water Heaters. Water heaters utilized for combined space-heating and water-heating applications shall comply with the standards referenced in Table 1203.2, and shall be installed in accordance with the manufacturer’s installation instructions. The total heating capacity of a dual purpose water heater shall be based on the sum of the potable hot water requirements and the space heating design requirements corrected for hot water first-hour draw recovery.

The installation of a dual purpose hydronic system should also give consideration to the temperature of the water with regard to health issues. In certain temperature regimes bacteria can actually reproduce quite well, thereby increasing the levels of exposure. Their ideal temperature for proliferation is between 77°F and 108°F. As water temperature increases, the bacteria’s concentration decreases. At sustained temperatures above 140°F, bacteria cannot survive. Hence, industry practice has been to maintain the DHW storage tanks at 140°F and mix down using an anti-scald mixing valve to a lower, safer temperature of operation.

Combination open systems should be designed to prevent the stagnation of water on the heating coils for an entire non-heating season.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: January 29, 2026