January 23, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 6 – WATER SUPPLY AND DISTRIBUTION

603.4.3 Access and Clearance. Access and clearance shall be provided for the required testing, maintenance, and repair. Access and clearance shall be in accordance with the manufacturer’s instructions, and not less than 12 inches (305 mm) between the lowest portion of the assembly and grade, floor, or platform. Installations elevated that exceed 5 feet (1524 mm) above the floor or grade shall be provided with a platform capable of supporting a tester or maintenance person.

Any installation of a backflow prevention device must take into consideration that at some point in time the device may need to be replaced or repaired. Testable assemblies will need clearance for testing; meaning that the tester must be able to access the test cocks and set up the test kit appropriately. AVBs, PVBs and SVBs must also have free area around them so that air flow in and out of the valves will not be compromised. Space needs to be given for each of these needs, not just the one-foot clearance from the bottom of the device (see Figure 603.4.3).

The code takes seriously the requirement for testing and maintenance of the device by requiring any installation above 5 feet to include a platform to work on the device. The measurement is usually taken from the center line of the device to the floor. Testing or repairing these devices takes space and sometimes involves bulky equipment. The requirement for the platform provides some safety for the plumber working on the device. It is also recognized that if a device is not easily accessible, a tester or maintenance worker might be reluctant to do a proper test, repair or even inspect the device.

BACKFLOW ASSEMBLY CLEARANCES

From the 2024 UMC Illustrated Training Manual, Chapter 5 – EXHAUST SYSTEMS

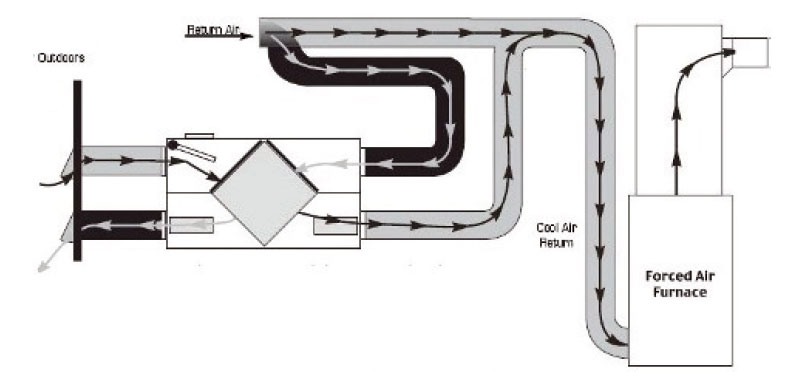

504.5 Heat Recovery Ventilation (HRV) and Energy Recovery Ventilation (ERV) Systems. Heat recovery ventilators (HRV) and energy recovery ventilators (ERV) shall be installed in accordance with their listings and comply with the appliance manufacturer’s installation instructions. Non-ducted heat recovery ventilators shall comply with UL 1815. Ducted heat recovery ventilators shall comply with UL 1812. Heat recovery ventilator and energy recovery ventilator ducts shall comply with Chapter 6.

Installation of these devices must conform to the manufacturer’s installation instructions. Typically, these would include mounting instructions, location of related registers and grilles and installation guidelines that include clearance for service. Ducts associated with this equipment must be in accordance with Chapter 6, Duct Systems (see Figure 504.5).

Heat Recovery Ventilation (HRV) and Energy Recovery Ventilation (ERV) systems are ventilation systems that transfer heat. Like an HRV, an ERV contains a heat exchanger that transfers heat from one air stream to another. Unlike an HRV, an ERV also moves moisture between the two air streams. The ASHRAE 90.1-2019 contains energy efficiency standards for buildings. This includes residential (except for low rise) and nonresidential buildings. Laboratories with VAV fume-hood exhaust or direct make-up air for the hoods are exempt.

HEAT RECOVERY VENTILATOR

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: January 23, 2025