January 16, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 9 – VENTS

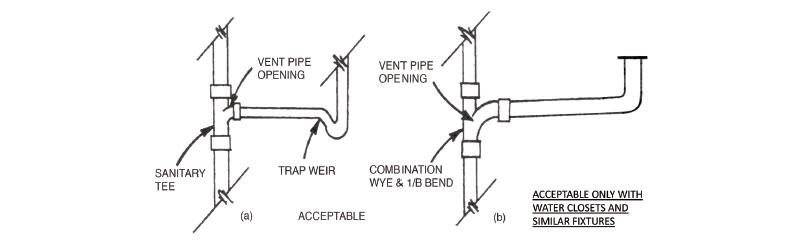

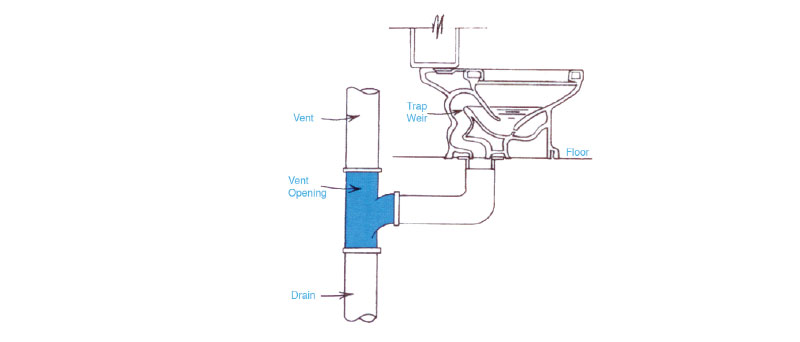

905.5 Location of Opening. The vent pipe opening from soil or waste pipe shall not be below the weir of the trap. Exception: Water closets and similar fixtures.

This section is similar to Section 1002.4. A vent pipe connection that is below the weir of the trap (see Definitions, Crown Weir (Trap Weir), and Figure 1001.2a) allows the potential for the fixture to induce self-siphonage (see commentary for Section 1002.2 for further discussion). Therefore, lengths of trap arms are limited and slopes are restricted to prevent the vent pipe connection to be below the weir of the trap (see Table 1002.2). If the vent connection is below the weir of the trap, this indicates that either the length or the slope of the trap arm is not code compliant.

THE PROPER FITTING FOR VERTICAL VENT

This will determine what type of fitting may be used to connect the trap arm, vent and fixture drain. For example, in vertical installations, the sanitary tee is the proper fitting to use for this connection. A combination wye and one eighth bend or a wye will not be allowed here since the opening of the vent would be below the weir of the trap (see Figure 905.5a and commentary for Section 1002.2 for further discussion).

The above requirement does not apply to water closets and similar siphon-waste fixtures. In reality, these fixtures are intentionally S trapped so that siphonage will occur, thereby emptying the entire trap seal and its contents with every flush. These fixtures rely on a mechanical refill device (ballcock) to seal the empty S trap. Consequently, the primary function of vents serving these fixtures is to provide a source of air to follow behind the surge of water being discharged from water closets and other below-the-weir waste/vent fixture connections (see Figure 905.5b).

WATER CLOSET VENT

From the 2024 UMC Illustrated Training Manual, Chapter 9 – INSTALLATION OF SPECIFIC APPLIANCES

914.7 Relief Openings. The design of the installation shall include adequate provisions to permit the direct gas-fired heating and forced ventilation appliances to operate at their rated airflow without overpressurizing the space served by the heater by taking into account the structure’s designed infiltration rate, properly designed relief openings, or an interlocked powered exhaust system, or a combination of these methods. [NFPA 54:10.8.7]

Installation design shall include adequate provisions for combustion and relief air to permit efficient operation of the equipment. Generally, an engineered system is required to be submitted for plan review to the Authority Having Jurisdiction (AHJ). Most system designers take into consideration either the structural infiltration rate or an interlocked power exhaust system to provide relief air. If adequate relief air is not provided, the pressure within the building increases, the airflow rate of the heater decreases and a potentially unsafe condition is created.

Air to direct-gas-fired industrial air heaters may be taken from the building, directly from the outdoors or a combination of both. Relief openings may be louvers or counterbalanced gravity dampers. If the dampers are motorized, they must be electrically interlocked so the equipment does not operate unless the louvers or dampers are in the open position.

The recirculation of air by an industrial-type heater may be hazardous in the presence of flammable solids, liquids and gases; explosive materials such as grain and coal dust; gunpowder and substances that are toxic when exposed to heat, like refrigerants and aerosols. Recirculation is not recommended in uninsulated buildings where outside temperatures fall below 32°F (0°C).

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: January 16, 2025