February 5, 2026

From the 2024 UPC Illustrated Training Manual, Chapter 4, PLUMBING FIXTURES AND FIXTURE FITTINGS

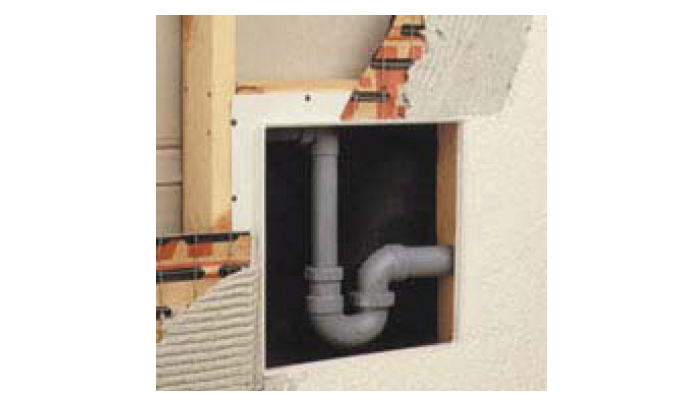

402.10 Slip Joint Connections. Fixtures having concealed slip joint connections shall be provided with an access panel or utility space not less than 12 inches (305 mm) in its least dimension and so arranged without obstructions as to make such connections accessible for inspection and repair.

“Slip joints” are defined in Section 221.0 as three piece assemblies involving the use of a friction ring and a compression washer, which is prone to be the weak link in this assembly (see Figure 402.10a). Potential failure of this washer may cause the joint to lose its gas-tight or water-tight status and leak. Thus, this joint, if concealed, shall be accompanied by a 12-inch by 12-inch access panel to allow for repair of the joint as in Figure 402.10b.

Two-piece assemblies are not slip joints by definition. Normally, these joints are comprised of a slip joint nut and a brass or nylon (plastic) ferrule. These materials have an anticipated lifespan that is equivalent to brass tubing. Therefore, no access panel is required. The same applies when tubing joints are assembled by soldering.

SLIP JOINT FITTING

ACCESS PANEL

From the 2024 UMC Illustrated Training Manual, Chapter 3, GENERAL REGULATIONS

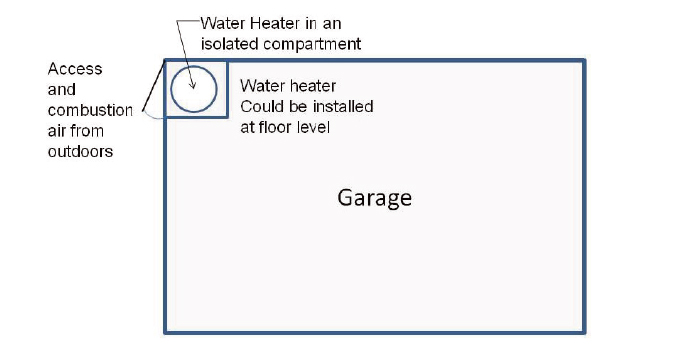

305.1.2 Access from the Outside. Where appliances are installed in a separate, enclosed space having access only from outside of the garage, such appliances shall be permitted to be installed at floor level, providing the required combustion air is taken from the exterior of the garage. [NFPA 54:9.1.10.3]

The code allows for the installation of an appliance at floor level, if it is in a separate compartment and has access and combustion air from outside the garage (see Figure 305.1.2).

EXCEPTION TO ELEVATING OF APPLIANCE ABOVE GARAGE FLOOR

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: February 5, 2026