February 27, 2025

From the 2024 UPC Illustrated Training Manual, Chapter Chapter 9, VENTS

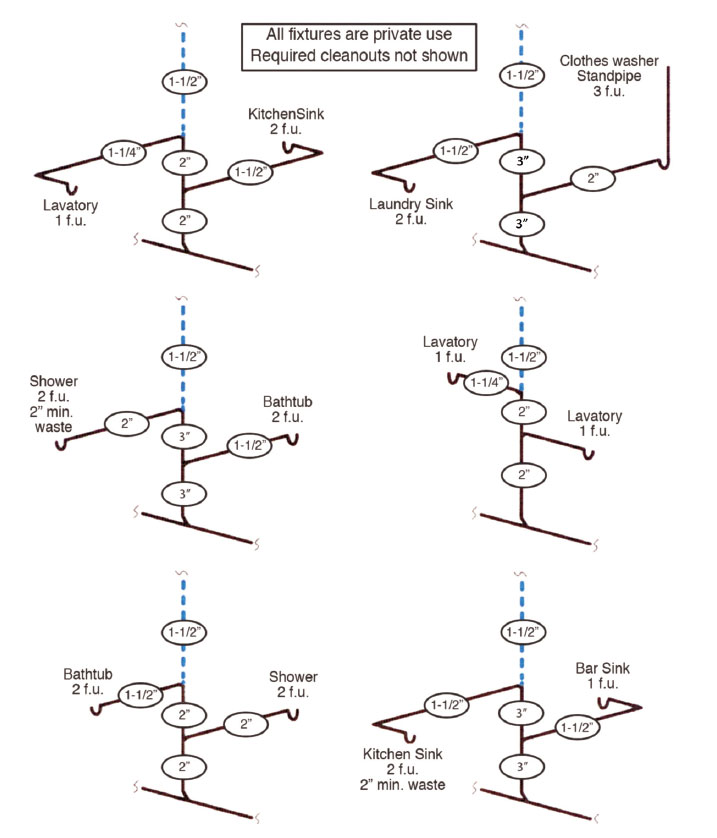

908.1.1 Size. The vertical piping between two consecutive inlet levels shall be considered a wet-vented section. Each wet-vented section shall be not less than one pipe size exceeding the required minimum waste pipe size of the upper fixture or shall be one pipe size exceeding the required minimum pipe size for the sum of the fixture units served by such wet-vented section, whichever is larger, but in no case less than 2 inches (50 mm) in diameter.

Section 908.1.1 requires each wet-vented section to be increased one pipe size larger than the minimum required pipe size, yet must be a minimum of 2 inches. For example, a lavatory having a 1 1/4 inches trap arm serving as a vertical wet vent is required to be increased one pipe size. However, the next pipe size is 1 1/2 inches, which is not permitted. Therefore, the pipe diameter needs to increase again to the minimum two inches (see Figure 908.1b). Therefore, the largest size required for the wet vent will be 3 inches. So the choices for the size of the wet vent section are either 2 inches or 3 inches.

WET VENT SIZING EXAMPLE 2

From the 2024 UMC Illustrated Training Manual, Chapter Chapter 4, VENTILATION AIR

403.7 Exhaust Ventilation. Exhaust airflow shall be provided in accordance with the requirements in Table 403.7. Exhaust makeup air shall be permitted to be a combination of outdoor air, recirculated air, and transfer air.

Table 403.7 lists several occupancy categories and the corresponding required exhaust rates. The exhaust rates are in the form of cfm/square foot, with few exceptions. The exhaust is to be replaced directly by outdoor air or recirculating air (that includes outdoor air), or indirectly through transfer air from other spaces.

One example of indirect replacement of exhaust is when transfer air from an adjacent space is provided to a toilet room to replace the exhausted air. This is a common practice intended to create a slightly negative pressure within the toilet room so that odors are kept within. However, supplying makeup air through an adjacent corridor that happens to be of fire-resistive construction must be avoided as this is prohibited by Section 602.7 of this code.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: April 8, 2025