February 19, 2026

From the 2024 UPC Illustrated Training Manual, Chapter 5, WATER HEATERS

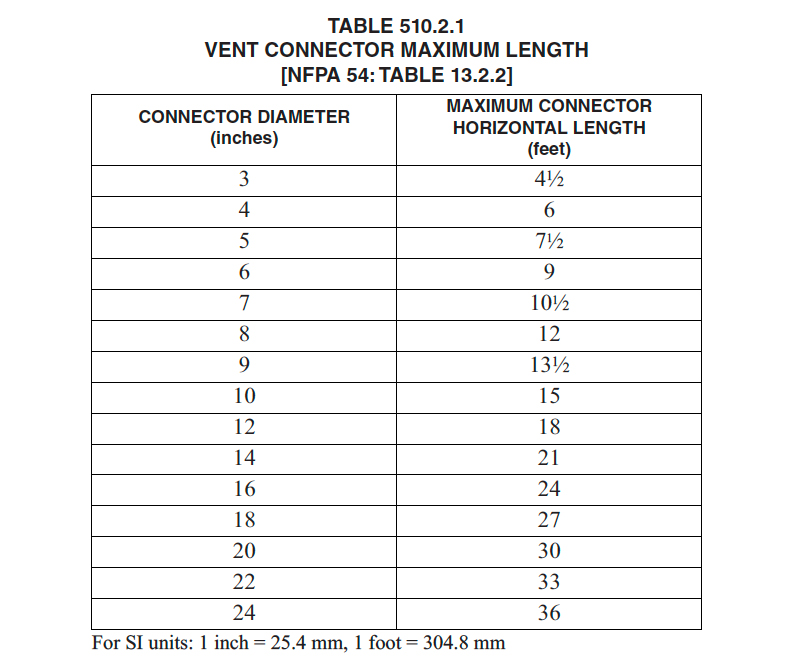

510.2.1 Vent Connector Maximum Length. The maximum vent connector horizontal length shall be 18 inches per inch (18 mm/mm) of connector diameter as shown in Table 510.2.1, or as permitted by Section 510.2.2. [NFPA 54:13.2.2]

The multiple appliance venting tables do not contain lateral length rows like those found in the single appliance tables. This section limits the vent connector length to 18 inches per inch of connector diameter as shown in Table 510.2.1. If these lengths are exceeded, Section 510.2.2 provides guidance on derating the tables accordingly.

510.2.2 Vent Connector Exceeding Maximum Length. The vent connector shall be routed to the vent utilizing the shortest possible route. Connectors with longer horizontal lengths than those listed in Table 510.2.1 are permitted under the following conditions:

(1) The maximum capacity (FAN Max or NAT Max) of the vent connector shall be reduced 10 percent for each additional multiple of the length listed in Table 510.2.1. For example, the maximum length listed for a 4 inch (100 mm) connector is 6 feet (1829 mm). With a connector length greater than 6 feet (1829 mm) but not exceeding 12 feet (3658 mm), the maximum capacity must be reduced by 10 percent (0.90 x maximum vent connector capacity). With a connector length greater than 12 feet (3658 mm) but not exceeding 18 feet (5486 mm), the maximum capacity shall be reduced by 20 percent (0.80 x maximum vent capacity).

(2) For a connector serving a fan-assisted appliance, the minimum capacity (FAN Min) of the connector shall be determined by referring to the corresponding single appliance table. For Type B double-wall connectors, Table 510.1.2(1) shall be used. For single-wall connectors, Table 510.1.2(2) shall be used. The height (H) and lateral (L) shall be measured according to the procedures for a single appliance vent, as if the other appliances were not present. [NFPA 54:13.2.3]

The common venting tables (the lower portion of Tables 510.2(1) through 510.2(5) are designed with the assumption that the vent connector is no more than 18 inches long for each inch of diameter. Sections 510.2.1 and 510.2.2, summarized as follows, provides guidance on how to handle connectors that are longer than this:

- The maximum capacity for vent connectors that exceed 18 inches per inch of diameter is reduced by 10 percent for each length of 18 inches per inch of vent diameter.

- The minimum capacity for connectors serving fan assisted appliances is determined differently for singlewall and Type B double-wall connectors, as described in Section 510.2.2.

From the 2024 UMC Illustrated Training Manual, Chapter 5, EXHAUST SYSTEMS

519.1 Where Required. Type II hoods shall be installed above equipment and dishwashers that generate steam, heat, or products of combustion, and where grease or smoke is not present.

Exceptions:

(1) Dishwashing machines connected to a Type II duct system and exhausted directly to the outdoors.

(2)Dishwashing machines with a self-contained condensing system listed in accordance with UL 921 and installed in a space where the HVAC system has been engineered to accommodate the latent and sensible heat load emitted from such appliances as approved by the Authority Having Jurisdiction. Such equipment shall be provided with an interlocking device to prevent opening of the appliance prior to completion of its cycle.

Type II hoods are required over other cooking equipment producing steam, heat, vapors or odors, such as bakery ovens, steam tables, coffee urns, dishwashers, etc.

Unless meeting Exceptions 1 or 2, this section also requires that Type II hoods be installed over commercial dishwashing machines, regardless of rinsing temperature. The amount of water vapor released by a tray of drying dishes is exactly the same whether they have been processed in a high or low-temperature dishwasher. The total amount of moisture released into the air will be the same for the same wetted area of the dishes. When the dishes are hot, the water vapor is not so readily seen, but it is nonetheless being released into the air.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: February 19, 2026