August 21, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 4 – PLUMBING FIXTURES AND FIXTURE FITTINGS

418.3 Location of Floor Drains. Floor drains shall be installed in the following areas:

(1) Toilet rooms containing two or more water closets or a combination of one water closet and one urinal, except in a dwelling unit.

(2) Commercial kitchens and in accordance with Section 704.3.

(3) Laundry rooms in commercial buildings and common laundry facilities in multi-family dwelling buildings.

(4) Boiler rooms.

As stated above, the floor drain is intended for emergency use. Public toilet rooms, commercial kitchens and laundry rooms are susceptible to overflow of the fixtures in the room and require a floor drain to contain that spillage. Boiler rooms require a floor drain for disposing of the accumulation of liquid wastes incident to cleaning, recharging, and routine maintenance. Single-dwelling units (homes, apartments or condos) are not required to have a floor drain.

From the 2024 UMC Illustrated Training Manual, Chapter 3 – GENERAL REGULATIONS

311.3 Prohibited Sources. Outside or return air for a heating or cooling air system shall not be taken from the following locations:

(1) Less than the separation distances to vents required by Section 802.6.1 and Section 802.8.

(2) Less than the separation distances required by Section 402.4.

(3) A hazardous or insanitary location, or a refrigeration machinery room as defined in this code.

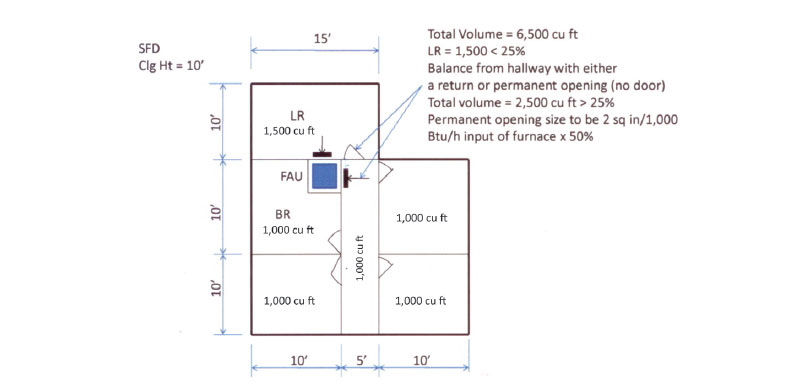

(4) An area, the volume of which is less than 25 percent of the entire volume served by such system, unless there is a permanent opening to an area the volume of which is equal to 25 percent of the entire volume served.

Exception: Such openings where used for a heating or cooling air system in a dwelling unit shall be permitted to be reduced to not less than 50 percent of the required area, provided the balance of the required return air is taken from a room or hall having not less than three doors leading to other rooms served by the furnace.

(5) A closet, bathroom, toilet room, kitchen, garage, boiler room, furnace room, or unconditioned attic.

(6) Rooms or spaces containing a fuel-burning appliance therein. Where such room or space serves as source of return-air.

Exceptions:

(1) This shall not apply to fireplaces, fireplace appliances, residential cooking appliances, direct vent appliances, enclosed furnaces, and domestic-type clothes dryers installed within the room or space.

(2) This shall not apply to a gravity-type or listed vented wall heating or cooling air system.

(3) This shall not apply to a blower-type heating or cooling air system installed in accordance with the following requirements:

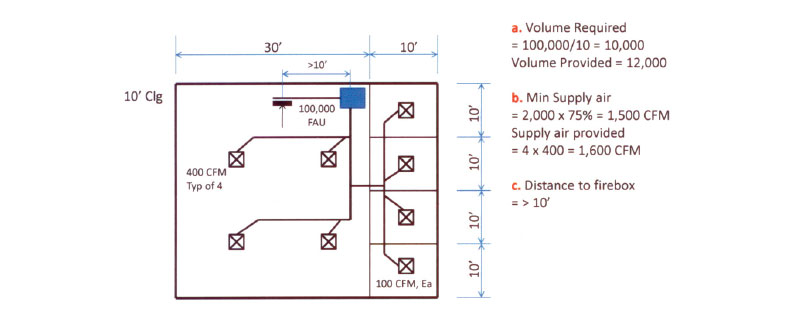

(a) Where the return air is taken from a room or space having a volume exceeding 1 cubic foot (0.03 m3) for each 10 Btu/h (0.003 kW) fuel input rating of fuel burning appliances therein.

(b) Not less than 75 percent of the supply air is discharged back into the same room or space.

(c) Return-air inlets shall not be located within 10 feet (3048 mm) from an appliance firebox or draft diverter in the same enclosed room or confined space.

This section prohibits outdoor air and return air from being taken from locations that are potential sources of contamination, odor, flammable vapors or toxic substances and also from locations that would negatively affect the operation of the furnace itself or other fuel-burning appliances.

It is also the intent of this section to avoid arrangements that could cause an air pressure imbalance, which could cause fuel-fired appliances to spill combustion products into the occupied space. Pressure imbalances can be avoided by making sure that the amount of supply air discharged into a room or space is approximately equal to the amount of return air taken from that room or space.

The intent of item (4) is to prevent the system from being starved for return air by the placement of the main or only return air intake in an area not meeting the minimum volume requirements (25%). Previously deleted code language allowed for the return to be placed in an area that does not meet the minimum volume requirement provided there are permanent openings to other areas in the building with an aggregate volume meeting the minimum required volume. The permanent openings were required to meet the minimum return air area (also deleted from earlier editions of the code) of 2 square inches per 1,000 Btu/h of the input rating of the furnace. The exception would allow the reduction of that area of the permanent openings, in dwelling units, to 50 percent of the required 2 square inches per 1,000 Btu/h of the input rating of the furnace, provided the opening is to a room meeting the conditions outlined in the exception, see Figure 311.3a for an example.

RETURN AIR FROM OTHER SPACES

Item (6) addresses a similar issue. A blower-type furnace is typically required to be enclosed in a compartment to isolate the return air from its fire box, combustion air source, and flue vent draft diverter. Item (6) Exception (3) would allow such an installation with very specific conditions:

(a) The return air is taken from a room with a volume exceeding 1 cu. ft. per 10 Btu/h input rating of the furnace.

(b) Minimum 75 percent of supply air is discharged back into this room.

(c) Return air to be at least 10 feet from the fire box and the flue vent draft diverter

See Figure 311.3b for an example.

BLOWER-TYPE FURNACE RETURN AIR EXCEPTION

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: August 20, 2025