December 11, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 6, WATER SUPPLY AND DISTRIBUTION

609.3 Under Concrete Slab. Water piping installed within a building and in or under a concrete floor slab resting on the ground shall be installed in accordance with the following requirements:

(1) Ferrous piping shall have a protective coating of an approved type; machine applied and in accordance with recognized standards. Field wrapping shall provide equivalent protection and shall be restricted to those short sections and fittings necessarily stripped for threading. Zinc coating (galvanizing) shall not be deemed adequate protection for piping or fittings. Approved nonferrous piping shall not be required to be wrapped.

(2) Copper or copper alloy tubing shall be installed without joints where possible. Where joints are permitted, they shall be brazed, and fittings shall be wrought copper.

For the purpose of this section, “within a building” shall mean within the fixed limits of the building foundation.

Knowledge of the mineral content of the soil in which piping is being laid is extremely important. This knowledge will dictate what type of piping material to use. For example, soil with high iron content is unsuitable for copper piping unless the copper is sleeved continuously for its entire length underground. Even if the copper is sleeved and there is a pinhole in the protective covering, the corrosion caused by galvanic action will occur even quicker than if the pipe was not sleeved at all. This is due to the concentration of the corrosion – transfer of ions – in one spot and will wear the pipe wall at a faster rate than if the transfer occurred along the entire length of pipe.

Of course copper pipe is not the only material that can be eroded. The point being made is, know the soils where the installation will occur and know the limitations of the materials that are being used.

From the 2024 UMC Illustrated Training Manual, Chapter 3, GENERAL REGULATIONS

303.6 Identification of Equipment. Where more than one heating, cooling, ventilating, or refrigerating system is installed on the roof of a building or within a building, it shall be permanently identified as to the area or space served by the equipment.

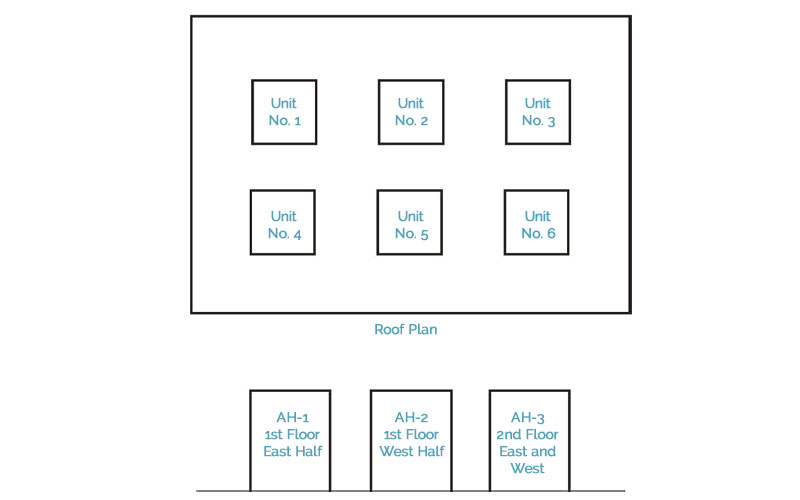

This requirement allows for inspection, servicing, repair or replacement of the correct equipment in the event of an emergency or scheduled maintenance, without interrupting neighboring spaces’ equipment. When appliances are not marked, service personnel typically cycle the equipment on and off to determine which equipment to service, unless the equipment or appliance is easily identifiable. Figure 303.6 illustrates examples of identification when more than one appliance is installed on the roof of a building or when appliances are grouped within a building.

IDENTIFICATION OF EQUIPMENT AS TO SPACE, AREA OR UNIT SERVED

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: December 11, 2025