March 28, 2024

From the 2024 UPC Illustrated Training Manual, Chapter 15 – ALTERNATE WATER SOURCES FOR NONPOTABLE APPLICATIONS

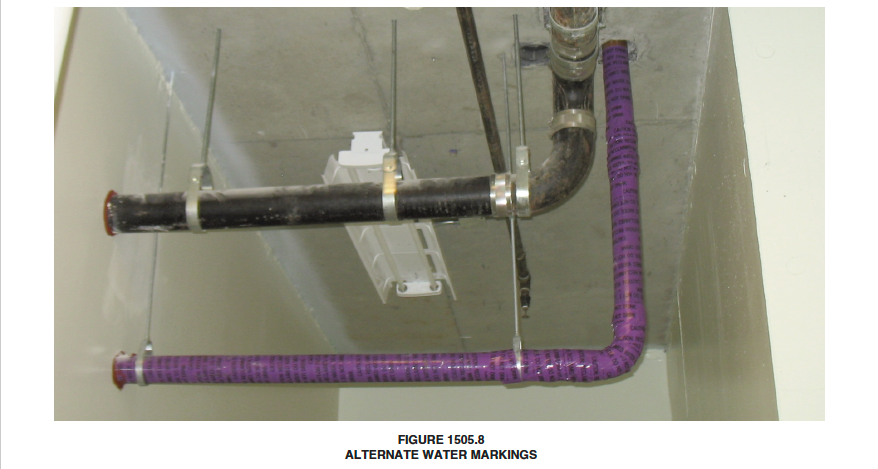

1505.8 Reclaimed (Recycled) Water System Color and Marking Information. Reclaimed (recycled) water systems shall have a colored background and marking information in accordance with Section 601.3 of this code.

According to Section 601.3, when dual (potable and nonpotable) systems are installed in the same building, the potable water piping shall be labeled a green background with white lettering. The background colors and required information shall be indicated every 20 feet and shall be labeled in each room and visible from the floor. (See the Alternate Water Sources Color and Marking Information Quick Reference Table following this section.) Many manufacturers are already supplying pre-lettered and colored piping for most applications.

All alternate water systems shall have a purple (Pantone color No. 512, 522C, or equivalent) background with upper case lettering and shall be field or factory marked as follows in the Quick Reference Table (see Figure 1505.8).

The Quick Reference Table shows the color requirements for a gray water subsoil irrigation system. Although it was not the intention of this code section to require the applicable color and markings for existing landscape irrigation piping when it converts to an alternate water source, the language does not include an exception for pre-existing uncolored and unmarked piping. Until this is further clarified in the code, check with the AHJ for existing piping requirements when converting to an alternate water source.

Quick Reference Table: Alternate Water Sources Color and Marking Information

| Gray water | “CAUTION: NONPOTABLE GRAY WATER, DO NOT DRINK” | Black letters |

| Reclaimed | “CAUTION: NONPOTABLE RECLAIMED WATER, DO NOT DRINK” | Black letters |

| On-site treated water | “CAUTION: ON-SITE TREATED NONPOTABLE WATER, DO NOT DRINK” | Black letters |

| Rainwater systems | “CAUTION: NONPOTABLE RAINWATER, DO NOT DRINK” | Black letters |

From the 2024 UMC Illustrated Training Manual, Chapter 12 – HYDRONICS

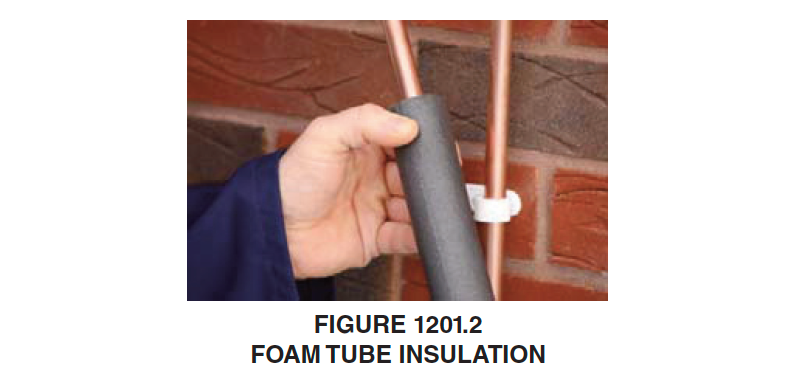

1201.2 Insulation. Surfaces within reach of building occupants shall not exceed 140°F (60°C). Where sleeves are installed, the insulation shall continue full size through them. Coverings and insulation used for piping shall be of material approved for the operating temperature of the system and the installation environment. Where installed in a plenum, the insulation, jackets, and lap-seal adhesives, including pipe coverings and linings, shall have a flamespread index not to exceed 25 and a smoke-developed index not to exceed 50 where tested in accordance with ASTM E84 or UL 723.

See Figure 1201.2.

The purpose of testing building materials using ASTM E84 is to minimize the smoke and flame spread during a fire, giving occupants of the building a better chance to escape, firefighters more time to control the fire, and to minimize building damage.

Flame spread index is a measure of the material’s ability to resist flames over its surface. The standard calls for not greater than 25 on a scale of 0-100, where untreated red oak lumber has a value of 100 and noncombustible cement-asbestos board has a value of 0.

Smoke-developed index is a measure of the concentration of smoke emitted by a material as it burns. The standard calls for not greater than 50 on the same relative scale (0-100) as the flame spread index.

UL 723, Test for Surface Burning Characteristics of Building Materials (Scope):

“This method of test for surface burning characteristics of building materials is applicable to any type of building material that, by its own structural quality or the manner in which it is applied, is capable of supporting itself in position or being supported in the test furnace to a thickness comparable to its intended use.

“The purpose of the test is to determine the comparative burning characteristics of the material under test by evaluating the spread of flame over its surface and the density of the smoke developed when exposed to a test fire, and thus to establish a basis on which surface burning characteristics of different materials are compared, without specific regard to all the end-use parameters that affect the surface burning characteristics.”

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: March 28, 2024