From the 2024 UPC Illustrated Training Manual, Chapter 3, GENERAL REGULATIONS

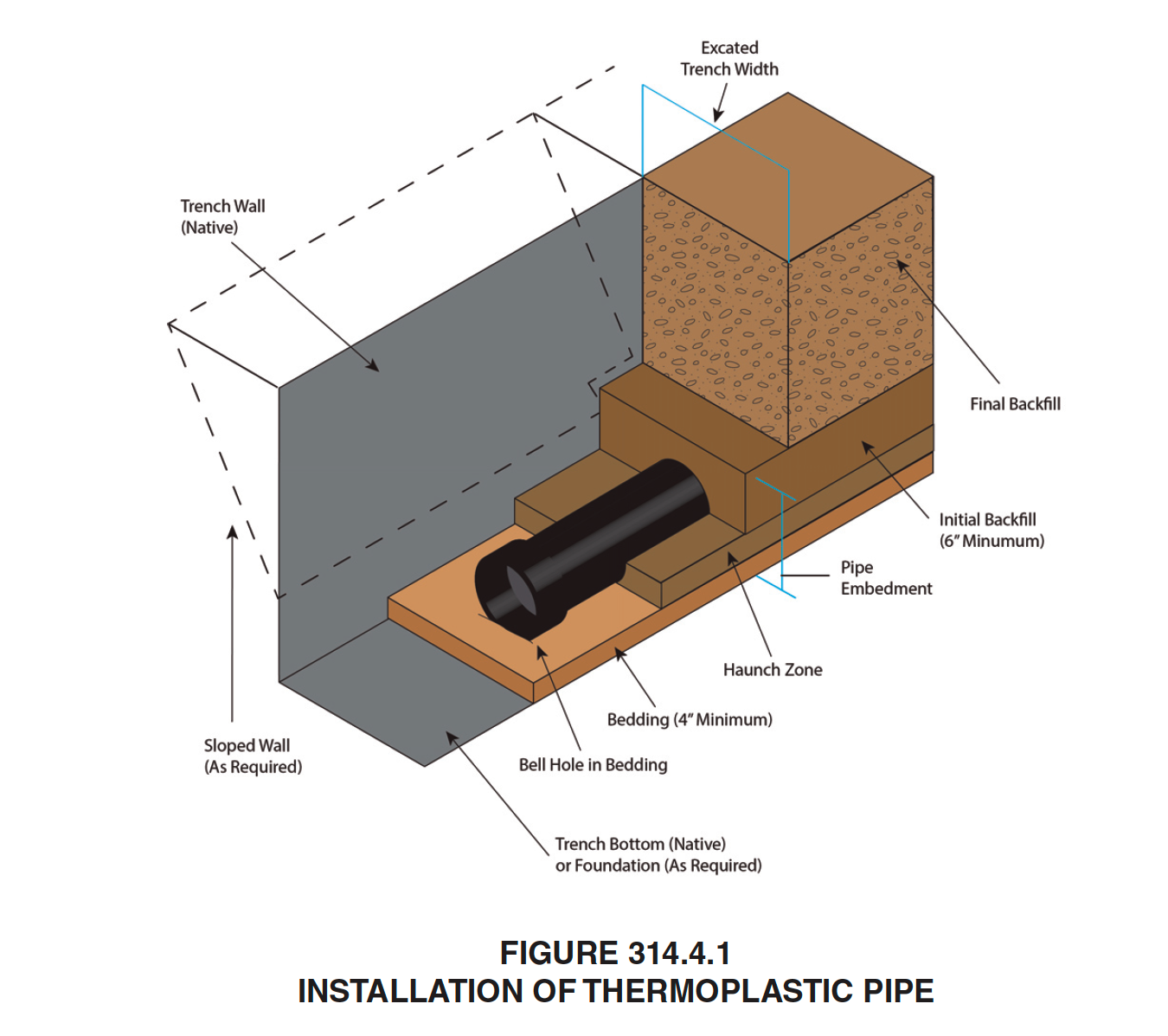

314.4.1 Installation of Thermoplastic Pipe and Fittings. Trench width for thermoplastic sewer pipe shall be not less than 1.25 times the outside diameter of the piping plus 12 inches (305 mm) or the outside diameter of the piping plus not less than 16 inches (406 mm). Thermoplastic piping shall be bedded in not less than 4 inches (102 mm) of granular fill supporting the piping. The backfill for thermoplastic piping shall be compacted along the sides of the piping in 6 inch (152 mm) layers and continue to not less than 12 inches (305 mm) above the piping. Compaction shall be not less than an 85 percent standard proctor density.

The standard for thermoplastic piping underground installation is ASTM D2321 which is found in Table 1701.1. This standard contains detailed requirements for the installation of thermoplastic pipe used for sewer and other gravity flow applications. Controlling the trench width enables the thermoplastic piping to gain side fill support from the compaction. If the trench width is too wide, the side fill support is more difficult to maintain and if it is too narrow then there is not enough room to compact the side fill support in 6 inch layers (see Figure 314.4.1).

The granular fill support allows the thermoplastic piping to embed itself in the fill and increase the bedding angle which takes advantage of the side fill support to prevent the piping from flattening due to the load of the backfill on top of the pipe. A cubic foot of dirt weighs about 45 pounds and if wet the weight increases. Because plastic piping is flexible the weight exerted on the top of the pipe forces the sides of the pipe to deflect outward.

The compaction is necessary to prevent the deflection of the pipe from the weight of the backfill. Compaction of the side fill prevents the weight on top of the pipe from causing the pipe to become oval and leak or fail because of the fracture of pipe walls. Undisturbed native soil is considered to be 100% standard proctor density so the 85% compaction attempts to restore the soil back to its original state. There is not a prescriptive methodology within this code section for multiple piping installations. Consult with your local authority having jurisdiction for trench widths on multiple piping installations.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: January 11, 2024