April 11, 2024

From the 2024 UPC Illustrated Training Manual, Chapter 8 – INDIRECT WASTES

801.4 Bar and Fountain Sink Traps. Where the sink in a bar, soda fountain, or counter is so located that the trap serving the sink cannot be vented, the sink drain shall discharge through an air gap or air break (see Section 801.3.3) into an approved receptor that is vented. The developed length from the fixture outlet to the receptor shall not exceed 5 feet (1524 mm).

Installing equipment and fixtures in a bar area can be a challenge. There is limited space to place all the equipment and fixtures needed for this installation. In most cases, only a back wall is available to vent the drainage system. This is no help when the sinks are in the counter across from the wall. Therefore, this section was included in the code to allow sinks in this type of installation to be installed with indirect wastes.

Although other sections of this chapter apply to this installation, the length requirement of indirect waste piping is excluded. In this installation it is limited to five feet. This is due to the fact that the items placed in a bar sink are prone to cause more odors than normal, so limiting the length will help to eliminate this problem. Great care should be taken at the time of fixture lay out and rough-in to prevent the later possibility of having to adjust the position of any sinks or plumbing to comply with this requirement.

From the 2024 UMC Illustrated Training Manual, Chapter 8 – CHIMNEYS AND VENTS

803.1.1 Vent Downsizing. Where the vent size determined from the tables is smaller than the appliance draft hood outlet or flue collar, the use of the smaller size shall be permitted, provided that the installation complies with all of the following requirements:

(1) The total vent height (H) is at least 10 feet (3048 mm).

(2) Vents for appliance draft hood outlets or flue collars 12 inches (305mm) in diameter or smaller are not reduced more than one table size.

(3) Vents for appliance draft hood outlets or flue collars larger than 12 inches (305 mm) in diameter are not reduced more than two table sizes.

(4) The maximum capacity listed in the tables for a fan assisted appliance is reduced by 10 percent (0.90 x maximum table capacity).

(5) The draft hood outlet is greater than 4 inches (102 mm) in diameter. A 3 inch (76 mm) diameter vent shall not be connected to a 4 inch (102 mm) diameter draft hood outlet. This provision shall not apply to fan-assisted appliances. [NFPA 54:13.1.2]

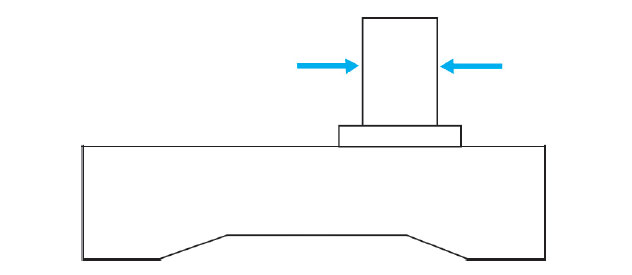

There is an economic incentive to using smaller vents wherever possible. If the vent is smaller than the draft hood or flue collar, venting problems can occur. The restrictions recognize and avoid these venting problems. Limits are placed on “downsizing” (see Figure 803.1.1). In particular, note that a 4-inch draft hood outlet shall not be reduced to 3 inches.

DOWNSIZING

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: April 10, 2024