April 4, 2024

From the 2024 UPC Illustrated Training Manual, Chapter 7 – SANITARY DRAINAGE

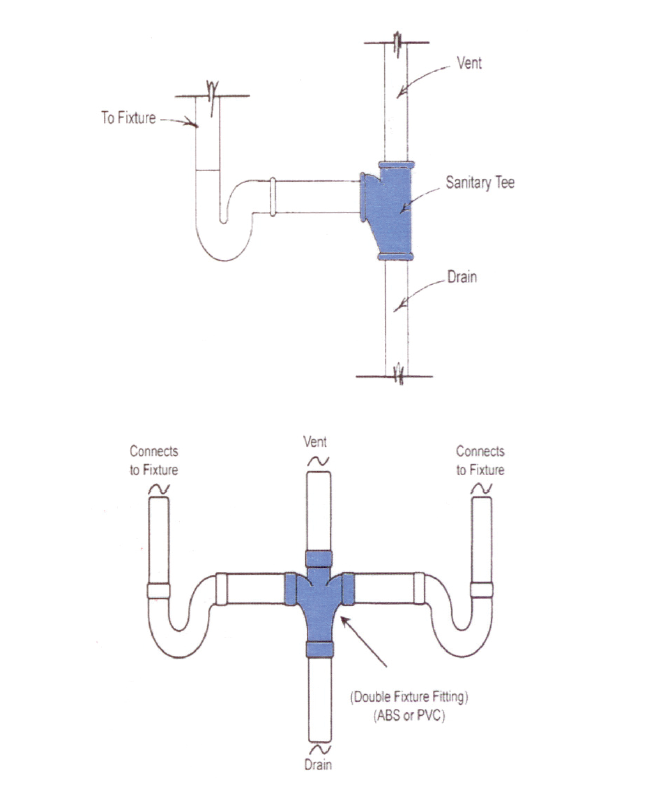

704.2 Single Vertical Drainage Pipe. Two fixtures set back-to-back, or side-by-side, within the distance allowed between a trap and its vent, shall be permitted to be served by a single vertical drainage pipe provided that each fixture wastes separately into an approved double-fixture fitting having inlet openings at the same level.

Grouping plumbing fixtures in certain areas of buildings can simplify the design of a plumbing system. In back-to-back and side-by-side installations, one drainage pipe serves two fixtures. The fixture fitting used is similar to the one used for single fixtures but with a dual opening. It is specially designed with more of an angle for the entry of flow into the barrel of the fitting. In this manner, the flow from one fixture cannot flow into the trap arm of the adjoining fixture. The proper term for this fitting is a “double-fixture fitting” (see Figure 704.2a).

DOUBLE FIXTURE FITTING

It also is sometimes referred to as a “Figure 5 fitting.” This is due to the illustration number as it appears in the cast iron fitting catalog. Figure 704.2b indicates inlet fittings for single and double-fixture fittings.

SANITARY TEE AND DOUBLE FIXTURE FITTING

From the 2024 UMC Illustrated Training Manual, Chapter 8 – CHIMNEYS AND VENTS

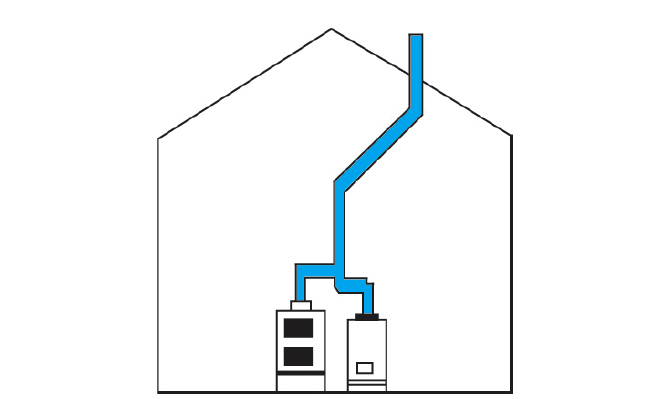

803.2.4 Vent Offsets. Where the common vertical vent is offset, the maximum capacity of the common vent shall be reduced in accordance with Section 803.2.5, and the horizontal length of the common vent offset shall not exceed 18 inches per inch (18 mm/mm) of common vent diameter (D). Where multiple offsets occur in a common vent, the total horizontal length of all offsets combined shall not exceed 18 inches per inch (18 mm/mm) of the common vent diameter. [NFPA 54:13.2.5]

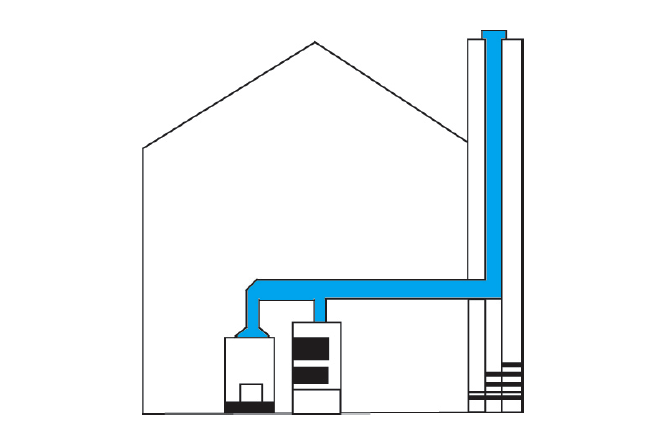

The “common vent” is the vertical vent or chimney only. A combination of vent connections prior to entering a vertical chimney or vent is considered to be a vent manifold (see Figure 803.2.4a), and guidance for sizing such is located here. Note that a chimney liner system that comes out through the breaching, as many do, should be considered a manifold. The capacity of the vent manifold is reduced by 10 percent from the table value. Also note that the length of a vent manifold is limited to 18 inches per inch of vent manifold diameter.

FIGURE 803.2.4A

VENT MANIFOLDS

Vent offsets, addressed in this section and illustrated in Figure 803.2.4b, typically occur high in the venting system and tend to reduce the draft produced. This reduction in draft is offset by the requirement for a 10 percent capacity reduction.

FIGURE 803.2.4B

VENT OFFSETS

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: April 4, 2024