FROM IDEA TO STORE SHELVES: HOW IAPMO GUIDANCE CRITERIA CREATE A PATH FOR PRODUCT INNOVATION

In 2000, Dr. Dan Wickham developed a blend of microbes that could unclog septic tank leach lines. He also designed a device to be used with it that would circulate air inside septic tanks so the bacteria could grow there in an environment where they wouldn’t ordinarily survive.

While there were new septic tanks on the market that used aeration to multiply bacteria, nothing was available that could be used to retrofit existing systems. Wickham’s solution changed that by allowing owners to avoid having to “rip everything out and either replace their systems or leach fields when they failed,” which he notes, “is terribly expensive.”

Describing it as a “fairly simple technology,” he began selling his solution locally without a permit because those systems where it was being installed were already approved. Unfortunately, that ended abruptly when he was summoned by the Sonoma County Health director because his product wasn’t certified to a standard.

Instead of citing him, however, the director recommended he apply for an IAPMO Guidance Criteria (IGC) standard. As one did not exist for his product at that time, Wickham worked closely with IAPMO todevelop IAPMO IGC 180-2003, to which the company is still listing its remediation systems for certification today.

Wickham also reports that SludgeHammer, Wickham’s company, has enlisted IAPMO’s help creating an ICG for another product for which it is currently designing a testing protocol in the field.

In a similar situation, the director of Engineering at Hydro Reserve, Stuart Bailin, also recently applied for an IGC he could use to certify an innovative wastewater treatment process after previously having received certification to an existing IGC at another company, Wahaso, for a novel product solution there.

Hydro Reserve’s technology, he explains, is “designed for the food and beverage industry where traditional treatment systems can struggle with waste variability and unexpected upsets, resulting in compliance issues and manufacturers having to face high surcharges due to wastewater exceeding discharge limits.

“We developed a compact system that removes the contaminants responsible for these fines while maintaining stability during wastewater fluctuations. By effectively separating wastewater into two streams — solids and clean water — it reduces surcharges while allowing for efficient waste handling and potential water reuse.”

By recovering high-quality water for non-potable uses, he concludes, facilities can significantly cut costs and reduce their environmental impact.

Bailin remembers being encouraged by the city of Los Angeles Health Department to get his equipment certified, and although it wasn’t essential for selling the system, he applied for an IGC because he believes it will benefit his company. “It says we meet the criteria for performance standards, and I think it’s very important that every product should be evaluated by a standard. I think it’s a good business model.

“So, we’re pushing the envelope by having a standard created so we can say, here’s a third-party standard created by IAPMO. And that gives us credibility.”

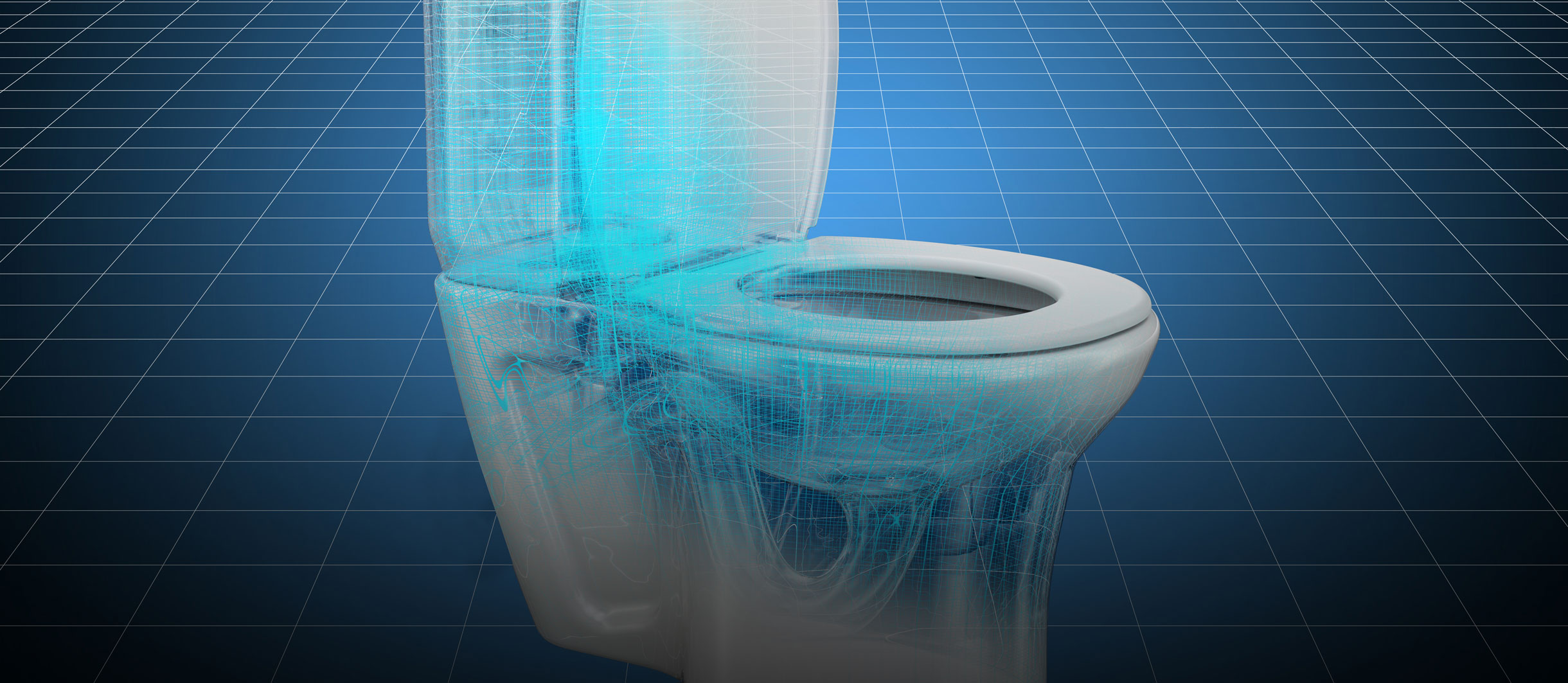

The IAPMO IGC® is intended for use by the industry for companies that have an innovative or novel new product ready to market but no standard exists to which they can certify it. GETTY IMAGES

National vs. Industry Standards

According to Hugo Aguilar, IAPMO senior vice president of Codes and Standards, as one of the world’s leading Standards Development Organizations (SDO), “IAPMO has processes in place for developing both national and industry standards.

“The primary differences between these two standards are their requirements and the number of steps necessary in order to develop them for certification.”

The most rigorous requirements are for national standards, which are accredited by the American National Standards Institute (ANSI) and/or the Standards Council of Canada (SCC). “IAPMO is accredited by both organizations,” Aguilar adds, “making it part of a very small group of SDOs that can develop national standards for both countries.”

The IAPMO IGC* is referred to as an industry standard, which is intended for use by the industry for companies like SludgeHammer and Hydro Fluid that have an innovative or novel new product ready to market but no standard exists to which they can certify it.

(Previously, Property Standards (PS), was also used as a designation for certifying and listing new products by IAPMO; now only IGC is used.)

Like national standards, IGCs are created

using an open-consensus process and is widely recognized and relied on both in the United States and in other countries. However, national standards are developed in accordance with requirements established by ANSI and the SCC, while industry standards are not, resulting in a lengthy process for developing them that can take up to two years from application to publication.

In contrast, IGCs use what Aguilar describes as an “expedited process requiring fewer steps and taking less time.” For example, IAPMO ANSI or SCC applicants have to post a public notice of intent to initiate the standards development process, which adds at least 30 days, while applicants for the IGC only need to file a project number. And while 45 days are mandated for public review with the ANSI-accredited process, and 60 days by the SCC’s, the IAPMO IGC only requires a 20-day review period.

IGCs provide a standard to which new products can be tested where no standard previously existed. PHOTO COURTESY OF IAPMO

Conditioning Marketplace Acceptance

Aguilar points out that model codes like IAPMO’s UPC contain common language requiring plumbing products to be certified to a recognized standard by a third-party organization.

No one is more acutely aware of this than Wickham, whose product was dead in the water after it was rejected by the Sonoma County Environmental Health Department because it lacked third-party certification.

Having it listed as a plumbing fixture “helped us there immediately,” he recalls, and since then SludgeHammer has experienced “steady growth in the marketplace.”

“There are copycats out there that haven’t been tested,” he says, and “anyone can certify a similar product to IAPMO IGC 180. But we have a large installer network in place across the country we’ve trained to market our system. It’s more of a process than a product you can sell off the shelf, so you have to understand it, and I think that’s scared away a lot of the competition.”

Bailin also acknowledges the marketplace value of having an IAPMO standard and certification based on his previous experience at Wahaso, where he received certification of his new wastewater treatment technology to IAPMO IGC 324-2019.

Focused on water harvesting solutions, Wahaso developed a system for treating water from sources in addition to gray water, which is what other technologies were limited to using. It also removed a greater quantity of contaminants from these sources as measured by a more accurate method for evaluating water quality called a Log Reduction Target that IAPMO devised for testing to the standard.

Bailin requested certification for this technology because he believes “eventually more and more jurisdictions will require some kind of third-party certification for water harvesting systems because they don’t have the resources to research every product themselves.

“While I’m not saying it’s the same as a testimonial,” he maintains, “when you’re certified to an IAPMO standard recognized in the United States, if not throughout the world, IAPMO is confirming your technology will do what you will say it will do.”

IGCs give regulators and the public confidence that products certified by IAPMO will perform as intended while also enhancing health and safety. GETTY IMAGES

Creating Confidence in Product Safety

IAPMO has been creating standards for use by the plumbing industry for more than 30 years. The purpose of these standards, Aguilar contends, is to give regulators and the public confidence that products certified by IAPMO will perform as intended while also enhancing health and safety.

IAPMO IGC standards also serve another purpose: to encourage the adoption of innovative new products by facilitating their entry into the marketplace.

Wickham appreciates the role IAPMO plays in doing this because of the freedom it gave him as an inventor.

“I loved working with IAPMO because their process made it possible to create a new standard that allowed my product to work as it should. I thought it was all very illuminating and I learned a lot of valuable things about how standards are developed and about the market and how to maneuver your way through it.”

Bailin concurs, stating that he especially liked the flexibility IAPMO’s IGC standard gave him when it came to evaluating his technology for certification.

“With Wahaso, IAPMO didn’t care about the source of the water being treated like other standards did; they only cared about the treatment results. In my opinion, that makes it a superior standard because it doesn’t dictate the design.

“Someone else can use a totally different design and certify to the same standard as long as it achieves the same results. They don’t tell you how to make it.”

Which is why Bailin came back to IAPMO for certifying his water treatment technology at Hydro Reserve, and why when asked, he would “absolutely” recommend the IAPMO IGC industry standards development process to others.

Making New Products Part of Our Lives

As more and more manufacturers list their products to an IGC, it may be replaced by a national standard in order to create acceptance for it in jurisdictions that still require certification to an ANSI-accredited standard.

As a result of initiating this process by developing an IGC, Aguilar states that,

“IAPMO has pioneered some of the most widely used standards in the industry for products that have become part of our daily lives.”

One product that made this transition recently, Aguilar notes, had “two IGC standards generated for it a couple of years ago, IAPMO IGC 349 and IAPMO IGC 115.” Used for detecting leaks in water supply systems, it automatically sent notifications to a smartphone app if any were discovered. After becoming popular for use by residential and commercial building owners and insurance companies, it began making its way into model codes and was eventually developed as national standard ANSI/CAN/IAPMO Z1349.

Aguilar anticipates scenarios like this becoming more common as we advance further and further into the digital age and awareness of how certification can give products a competitive edge continues to grow among manufacturers and inventors like Wickham and Bailin.

When that happens, he wants to assure them that as the “go-to source” for aiding the entry of innovative new products into the marketplace, IAPMO’s Standards Department stands ready to serve them with the development of IGC industry standards.

IGCS THAT BECAME NATIONAL STANDARDS

- CSA B45.8/IAPMO Z403 (Terrazzo, Concrete, Composite Stone, and Natural Stone Plumbing Fixtures) was initiated as an industry standard, IAPMO PS 99 (Terrazzo, Marble, Concrete, Granite and Slate Plumbing Fixtures), in 1996.

- CSA B45.11/IAPMO Z401 (Glass Plumbing Fixtures) was initiated as an industry standard, IAPMO IGC 172 (Glass Lavatories and Sinks), in 2002.

- CSA B45.11/IAPMO Z402 (Aluminum and Copper Plumbing Fixtures) was initiated as an industry standard, IAPMO IGC 194 (Copper Alloy or Aluminum Alloy Sinks and Lavatories), in 2004, and as IAPMO IGC 217 (Metallic Bathtubs, Shower Pans, and Whirlpool Bathtubs), in 2005.

Stephen Webb

Last modified: April 8, 2025