ADDRESSING THE WORLD’S SANITATION SHORTCOMINGS BY SETTING THE STANDARD FOR NON-SEWERED SOLUTIONS

Safe sanitation is essential for healthy well-being and the prosperity of people everywhere. Around the world, less than 60 percent of fecal waste is being properly treated, with the rest being released to the environment untreated. According to The Sustainable Organic Integrated Livelihoods (SOIL), in Haiti, only 30 percent of the population has access to sewered sanitation and less than 1 percent of the human waste there is safely treated. The lack of safe treatment there has fueled one of the largest and most virulent cholera epidemics in recent global history.

More than 3.5 billion people worldwide live without safe sanitation. Diseases transmitted through human-waste-contaminated water are responsible for 115 deaths every hour in Africa alone. More than 60 trillion gallons of untreated wastewater enters the oceans annually. This unhealthy environment calls for a solution for treating water prior to being introduced back into the environment and a more sustainable sanitation system to address areas where there is a lack in infrastructure.

Since the early 1900s, there have been great strides and innovations in almost all areas in our lives, such as flight and mobile phones for example, but sanitation has remained relatively stagnant. Many companies and research institutions have been working to improve and accelerate innovation in non-sewered sanitation technologies. Water, Sanitation and Hygiene (WASH) programs seek to advance and increase access to sustainable sanitation through the development and commercialization of transformative toilet technologies. In 2011, the Reinvent the Toilet Challenge sought to spur the creation of new toilet treatment technologies. According to the Gates Foundation website, the core focus was on affordable, complete, and sustainable waste treatment solutions that eliminate pathogens and are energy efficient/off-grid and resilient.

History of ANSI/CAN/ IAPMO/ISO 30500

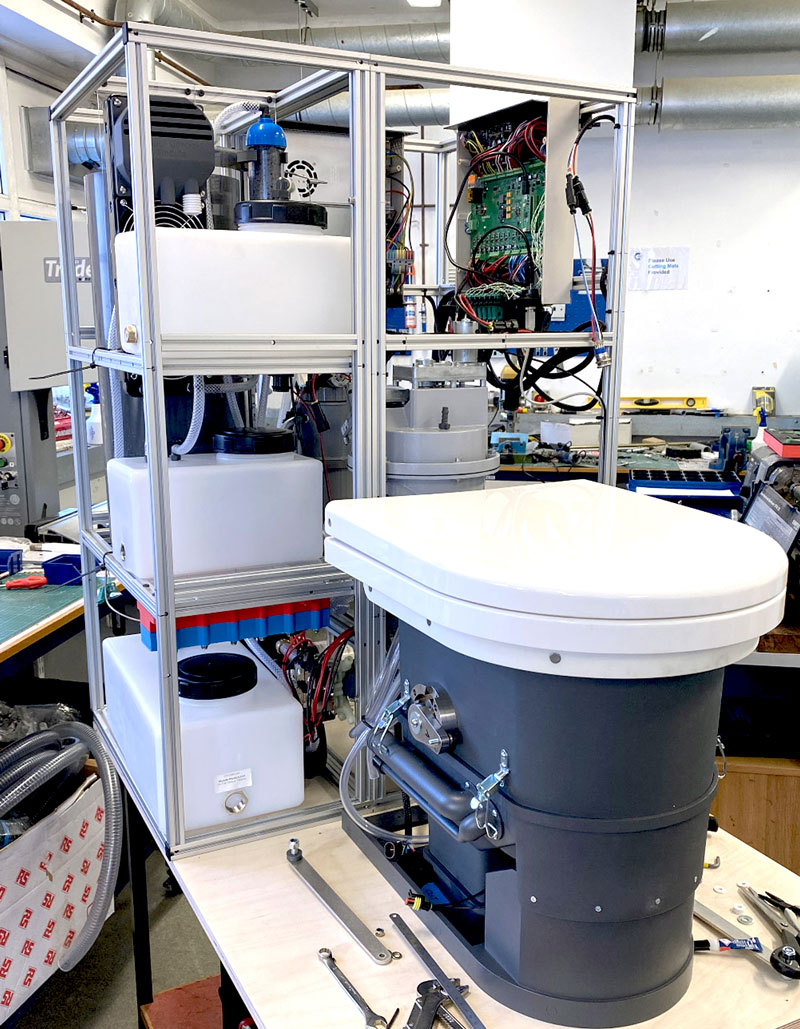

Cranfield Circular Toilet research and development at Cranfield University. | PHOTO COURTESY OF CRANFIELD UNIVERSITY

Part of this overall effort included the need for broad consensus performance requirements, leading to the development of the ISO 30500 standard published in October 2018.

ISO 30500 is a voluntary international product standard for non-sewered sanitation systems (NSSS) that provides general safety and performance requirements for the product design and performance testing of prefabricated integrated treatment units that are not attached to a network sewer or drainage system. The standard was developed by 32 participating countries and 16 observing members, with the American National Standards Institute (ANSI) serving as the U.S. Technical Advisory Group (TAG) Administrator. Canada participated in the development of the international standard through the Canadian Mirror Committee. IAPMO participated as a member of the U.S TAG.

In November 2018, the first Reinvented Toilet Expo was held in Beijing. The expo featured products aimed at accelerating the adoption of innovative, non-sewered sanitation technologies. Many of the non-sewered sanitation products either met or were in the process of meeting the requirement of ISO 30500.

To align with global trade and promote best practices, ANSI encourages the national adoption of ISO standards to ensure compatibility and consistency with global standards. This adoption facilitates trade, reduces barriers, and promotes interoperability between countries. IAPMO was selected as the Accredited Standards

Developer to proceed with the national adoption of ISO 30500. IAPMO, being accredited by both ANSI and the Standards Council of Canada (SCC), recognized the opportunity for a binational adoption of ISO 30500 in the United States and Canada.

Participants at the Reinvent the Toilet Expo held November 2018 in Beijing, China. | PHOTO BY SUN GIL KIM, ISO PC 305 CHAIR SGK CONSULTING

In November 2019, the first edition of ANSI/ CAN/IAPMO/ISO 30500 was published and ready for adoptions by jurisdictions and model codes in both the United States and Canada. The 2020 Water Efficiency and Sanitation Standard (WE•Stand) was the first efficiency standard to recognize ANSI/CAN/IAPMO/

ISO 30500, followed by the 2024 Uniform Plumbing Code (UPC®) earning the same distinction as the first model plumbing code, both of which are accredited by ANSI. Other codes and standards have since followed.

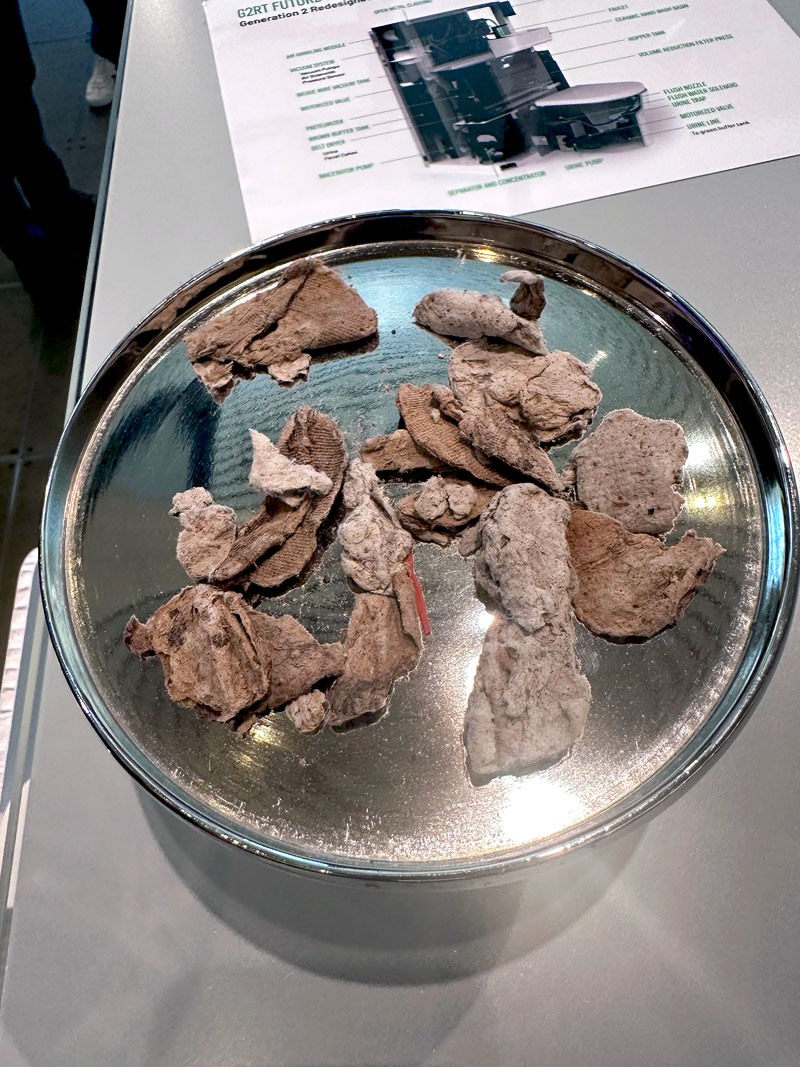

Pathogen-free char that collects in a chamber at the base of the Cranfield Circular Toilet

following processing. | PHOTO COURTESY OF HUGO AGUILAR

About ANSI/CAN/ IAPMO/ISO 30500

The ANSI/CAN/IAPMO/ISO 30500 standard is a voluntary standard that contains human health, environmental, air emission, acoustics and odor parameters. It addresses health requirements such as bacteria, protozoa, viruses, and helminths. The environmental parameters include BOD, COD, pH, temperature, total nitrogen, total phosphorus, TSS and trace elements. The air emissions parameters include CO, NOx, SO2, dust, arsenic, oxygen, and others. It contains criteria for the safety, functionality, usability, reliability, and maintainability of the system, as well as its compatibility with environmental protection goals.

ANSI/CAN/IAPMO/ISO 30500 specifies general safety and performance requirements for design and testing as well as sustainability considerations for non-sewered sanitation systems (NSSS). A NSSS, for the purposes of this article, is a prefabricated integrated treatment unit, comprising frontend (toilet facility) and backend (treatment facility) components that:

a) Collect, convey, and fully treat the specific input within the system, to allow for safe reuse or disposal of the generated solid, liquid, and gaseous output

b) Do not need to be connected to a networked sewer or networked drainage system

The standard is applicable to sanitation systems that are either manufactured as one package, or manufactured as a set of pre-fabricated elements designed to be assembled in one location without further fabrication or modification that influences the system function.

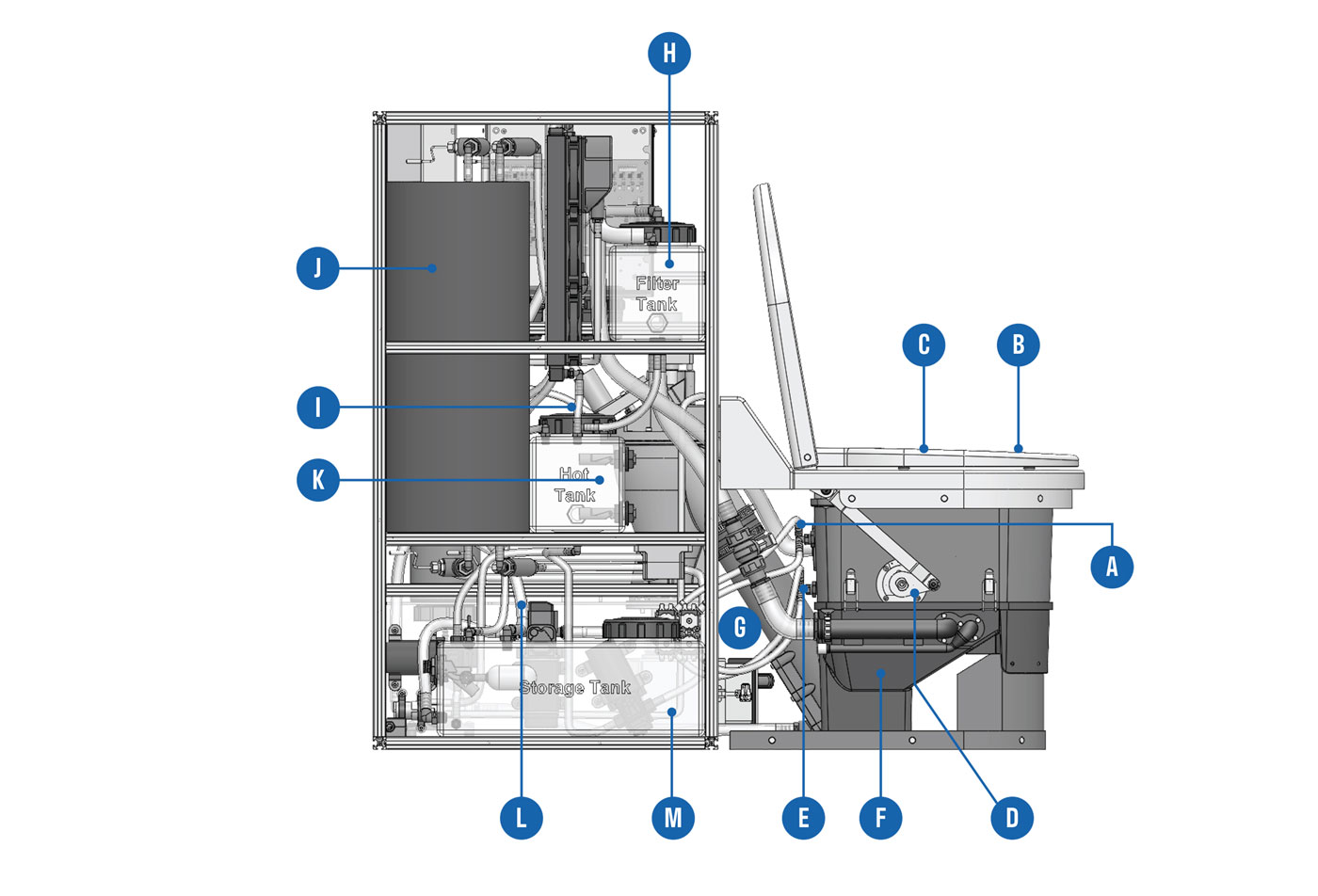

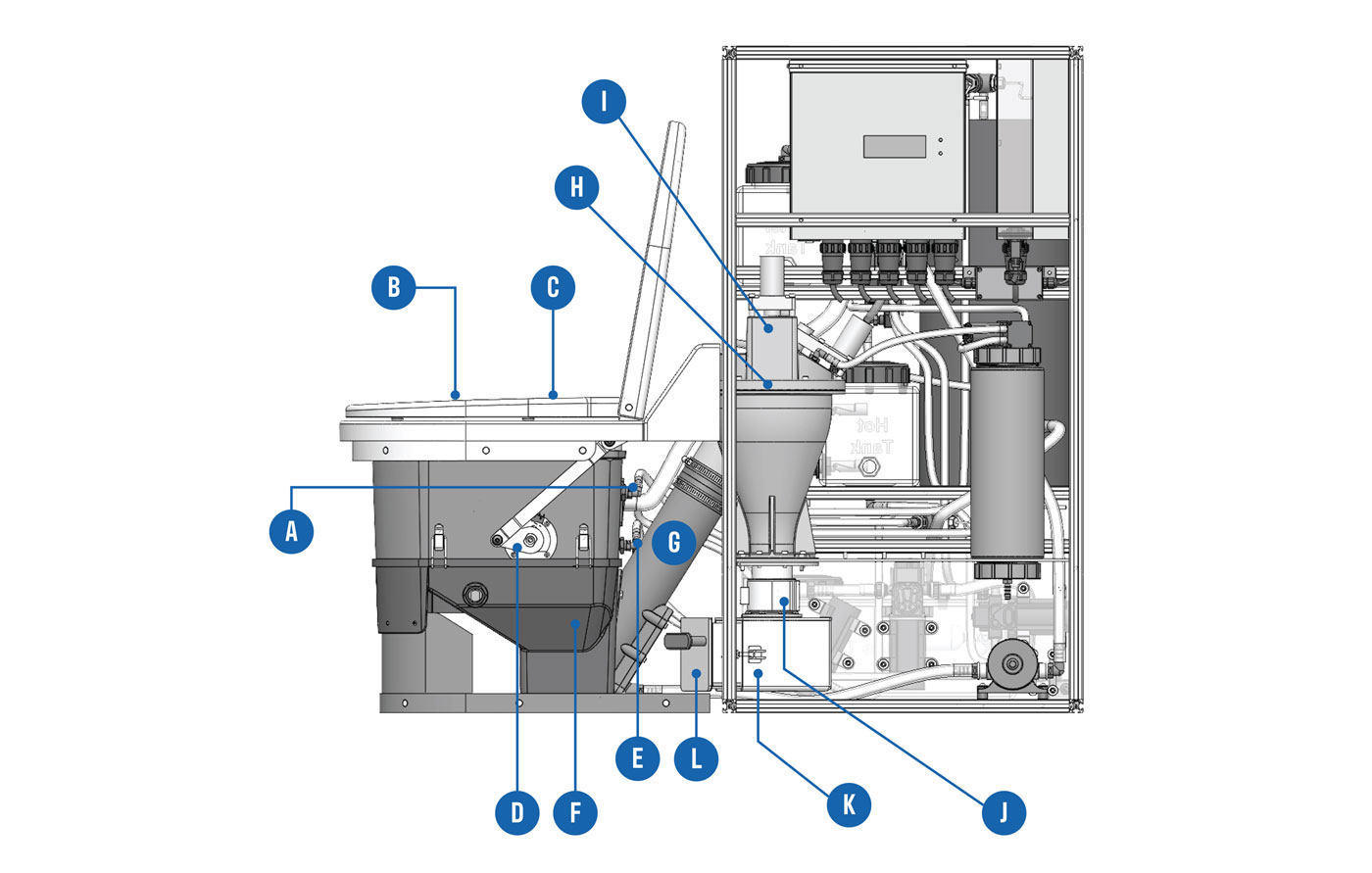

Some of the systems that are designed to meet the requirements of ISO 30500 and ANSI/ CAN/ IAPMO/ISO 30500 include the recently certified Ecosan community toilet system, the Bio-Thermal prototype (https://news.samsung. com/global/samsung-develops-prototype-reinvented-toilet-in-partnership-with-the-bill-melinda-gates-foundation), the Cranfield Circular Toilet (https://www.discover gates.org/ exhibitions/a-better-way-to-go/toilets/cranfield- toilet/), the Georgia Tech G2RT (https://g2rt. research.gatech.edu/), and others. The image on the left shows the functionalities of a Cranfield Circular Toilet for liquid processing, and previous page shows the functionalities of the solid processing.

A Pre-wetting nozzle

B Rotating bowl

C Self-sealing system to control odor

D Rotating bowl mechanism

E Nozzle spray to clean bowl

F Lower tank

G Dewatering screw separates liquids and solids

H Solids enter and processed in torrefacation unit—operates in low- oxygen environment and temperatures 150-300°C

I Creates solids and water in vapor form Now pathogen-free solids collect in the bottom of the chamber

J Removable storage container for pathogen- free char

K Char disposal output

CIRCULAR TOILET – LIQUIDS PROCESSING

A Pre-wetting nozzle

B Rotating bowl

C Self-sealing system to control odor

D Rotating bowl mechanism

E Nozzle spray to clean bowl

F Lower tank

G Dewatering screw separates liquids and solids

H Liquids pumped up into holding tank, enough to service 5 people for 24 hours

I Liquid heated before entering membrane unit

J Membrane distillation unit—only liquid in vapor form passes through these hydrophobic membrane pores

K Concentrated urine builds up in hot tank, diverted to the solids processing module

L Pathogen free vapor exits membrane

M Cooled, condensed, disinfected by UV, and stored in tank to be re-used for flushing

The Cranfield Circular Toilet is a compact and self- contained off-grid system that processes waste on-site.

GRAPHIC COURTESY OF CRANFIELD UNIVERSITY

What is Next for ISO 30500

Development and certification testing has shown some areas that would benefit from updating to make the standard more efficient without compromising human safety and environmental requirements. The ISO committee PC 305 met for the last time in Beijing in January 2025 to finalize ISO 30500, which is expected to publish later this year. Changes include an allowance to forgo Log Reduction Value (LRV) testing for helminth ova if spiking material is not available, and reduction of buffer lab test days, to name a couple. IAPMO, as part of the PC 305 U.S TAG, looks forward to bringing the updated ISO 30500 to the United States and Canada as a national adoption.

Hugo Aguilar, P.E.

Last modified: July 2, 2025