IAPMO published the 2024 Uniform Plumbing Code® (UPC®) and the 2024 Uniform Mechanical Code® (UMC®) in May. The codes were improved with safety provisions addressing hot-water recirculation systems, private well water tanks, water reuse requirements, non-sewered sanitation systems, indoor horticulture, tiny houses, onsite stormwater treatment systems, minimum ventilation filtration, Group A2L refrigerants, district ambient temperature loop, and CO2 monitoring, just to list a few.

The International Association of Plumbing and Mechanical Officials (IAPMO®) continues to protect the public through its ANSI-accredited development process where third-party oversight assures a true consensus document. The Uniform Codes maintain the necessary balance between prescriptive requirements and allowable performance standards; it details exactly how a system needs to go together.

The provisions in the Uniform Codes are specifically written to protect the public and to aid jurisdictions wherever adopted. The Uniform Codes are the only plumbing and mechanical codes that contain the latest technology with the appropriate safety provisions.

A few of the improvements made to the UPC and UMC are as follows:

Key Changes to the 2024 UPC

Water Reuse

The UPC has long been the leader in providing innovative provisions for the industry. The 1994 UPC was the first model code to include provisions for nonpotable applications as well as the first to include provisions for non-potable rainwater catchment systems. Since then, the UPC Technical Committee has updated chapters 15 and 16 with additional water quality measures that protect the health and safety of the public.

Alternate Water Sources for Nonpotable Applications

1501.7 Minimum Water Quality Requirements. The minimum water quality for alternate water source systems shall meet the applicable water quality requirements for the intended application as determined by the Authority Having Jurisdiction. In the absence of water quality requirements, for on-site treated nonpotable systems, the water quality requirements of IAPMO IGC 324 or NSF/ANSI 350 shall apply.

Exception: Water treatment is not required for gray water used for subsurface irrigation.

1506.8 On-Site Treated Nonpotable Water Devices and Systems. Devices or equipment used to treat on-site treated nonpotable water to maintain the minimum water quality requirements determined by the Authority Having Jurisdiction shall be listed and labeled (third-party certified) by a listing agency (accredited conformity assessment body) or approved for the intended application. Devices or equipment used to treat on-site treated nonpotable water for use in the water closet and urinal flushing, surface irrigation, and similar applications shall comply with IAPMO IGC 324, NSF/ANSI 350 or approved by the Authority Having Jurisdiction.

Nonpotable Rainwater Catchment Systems

1603.4 Minimum Water Quality.

The minimum water quality for harvested rainwater shall meet the applicable water quality requirements for the intended applications as determined by the Authority Having Jurisdiction. In the absence of water quality requirements determined by the Authority Having Jurisdiction, the minimum treatment and water quality shall be in accordance with Table 1603.4, IAPMO IGC 324 or NSF/ANSI 350.

Exception: No treatment is required for rainwater used for subsurface or non-sprinkled surface irrigation where the maximum storage volume is less than 360 gallons (1363 L).

The revisions to sections 1501.7, 1506.8, and 1603.4 include IAPMO IGC 324 and NSF 350 as acceptable standards for products used in graywater and rainwater applications. It provides the flexibility to utilize IAPMO IGC 324 or NSF 350 depending on the application. NSF 350 is not new to the UPC as it was already listed as an acceptable standard in the previous 2021 edition of the UPC. The main difference is that the IAPMO IGC 324 standard utilizes Log Reduction Targets (LRTs) methodology to determined water quality and NSF 350 is limited to 1,500 gal/day. The LRTs found in the IGC 324 were based on the San Francisco Department of Public Health for onsite water reuse. See the image on the following page for an example of an IGC 324 compliant-product.

1603.5 Rainwater Storage Tanks. Rainwater storage tanks shall comply with IAPMO/ANSI Z1002 and be installed in accordance with Section 1603.6 through Section 1603.12.

The previous edition only covered installation provisions for the tanks. In contrast, IAPMO/ ANSI Z1002 contains material and performance requirements as well as testing procedures for the safe use in their intended application.

An example of a rainwater storage tank in compliance with IAPMO/ ANSI Z1002.

PHOTO COURTESY OF RAINHARVEST SYSTEMS

This commercial rainwater harvesting system is an example of an IGC 324-compliant-product.

PHOTO COURTESY OF WAHASO

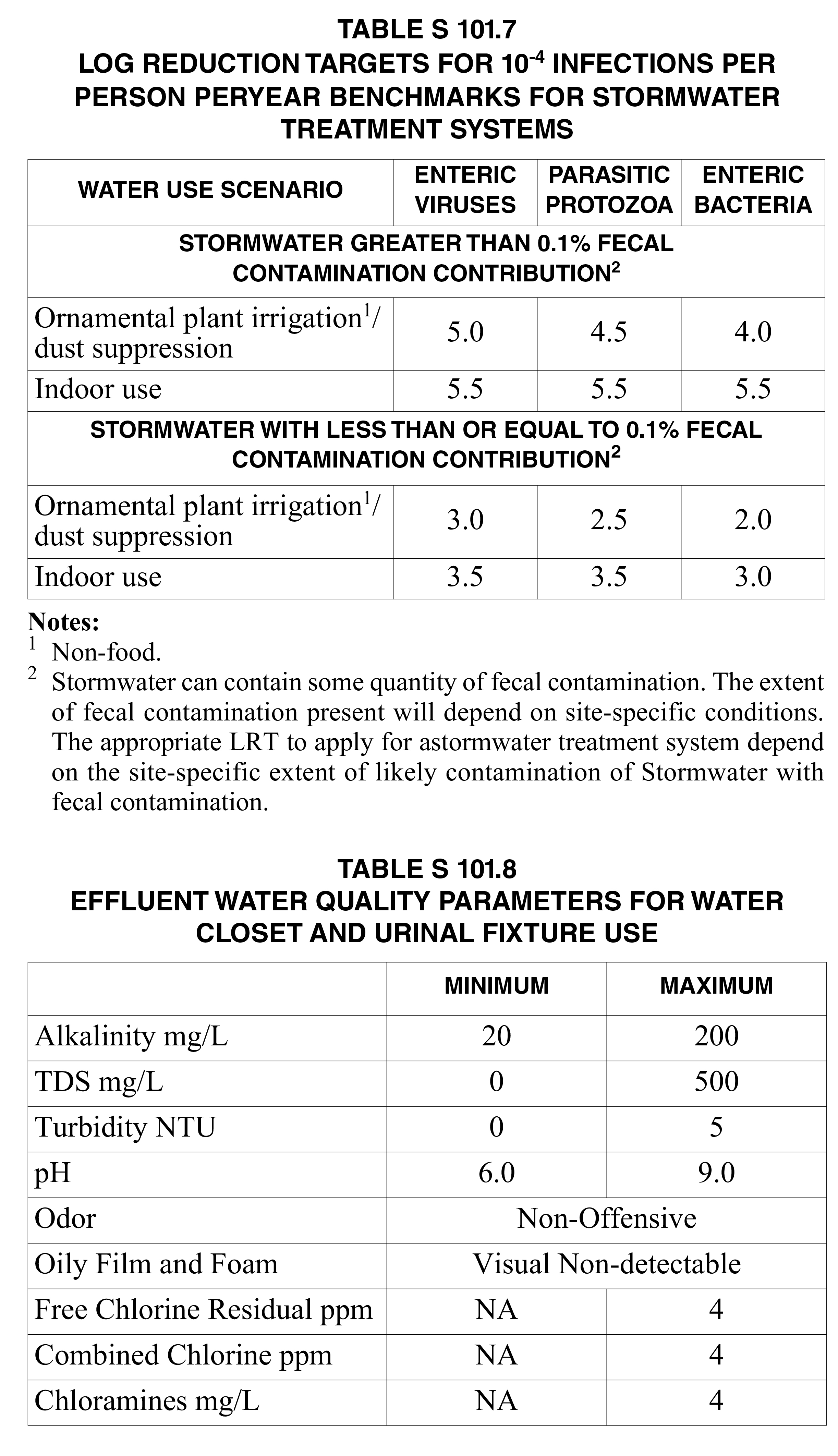

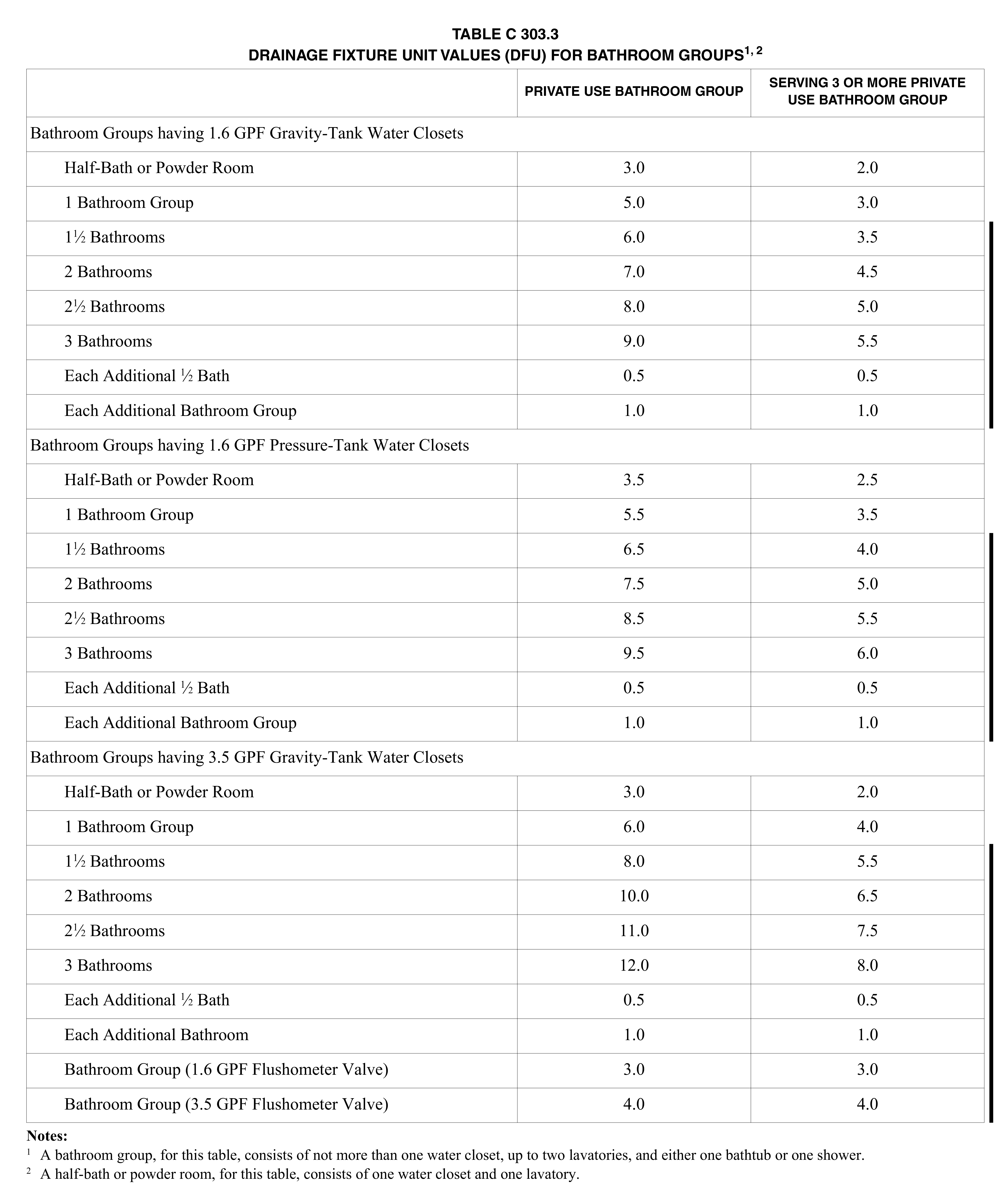

Stormwater

We talked about greywater and rainwater, but what about stormwater? The storm- water provisions in the UPC were updated to include provisions in an appendix that apply to the water quality, monitoring, design, construction, alteration, repair, and operation requirements of onsite stormwater treatment systems for non- potable use. As shown, Appendix S utilizes Log Reduction Targets as a parameter for the water quality in Table S 101.7 and Table S101.8. The appendix also includes Table S 101.11 based on risk levels and monitoring parameters.

APPENDIX S – ONSITE STORM-WATER TREATMENT SYSTEMS

(entire appendix not shown)

S 101.7 Log Reduction Targets. Storm water treatment systems shall be designed to meet the log reduction targets as set forth in Table S 101.7. To meet the log reduction in Table S 101.7, treatment processes used in stormwater systems shall comply with Section S 101.8 for validation or be operated according to conditions approved by the Authority Having Jurisdiction.

S 101.11 Monitoring Requirements. Monitoring of stormwater treatment systems shall be based on the risk level in accordance with Table S 101.11(1). The parameters listed in Table S 101.11(2) shall be monitored by sensors placed in the effluent of the system and connected to a smart controller. The smart controller shall activate an alarm when the parameters in Table S 101.11(2) are outside the specifications and shall shut the system down when the alarm is not acknowledged after a period of 8 hours has elapsed. For Category 2, quarterly grab samples shall be taken out of the effluent and analyzed by an accredited lab. The sensors’ accuracy and response shall be validated upon commissioning of the system by an independent third party.

Pipe Sizing

The 2018 edition of the UPC first added updated and modernized pipe sizing provisions that reduced the pipe size drastically with the use of Appendix M (Water Demand Calculator). IAPMO initiated a Memorandum of Understanding (MOU) with the American Society of Plumbing Engineers (ASPE) and the Water Quality Research Foundation (WQRF) to form a special task force to revise the methodology for properly estimating premise plumbing water supply demands in response to the increased use of water- conserving plumbing fixtures, fixture fittings and appliances, and the subsequent decreased demand for water in single- and multi-family residences.

IAPMO encourages the industry and other standards developers to utilize the proven Water Demand Calculator for consistency, and to avoid confusion in the industry. When all is said and done, we have a responsibility of protecting the public. Appendix M is also available as a stand-alone option for jurisdictions to utilize, regardless of the adopted plumbing code.

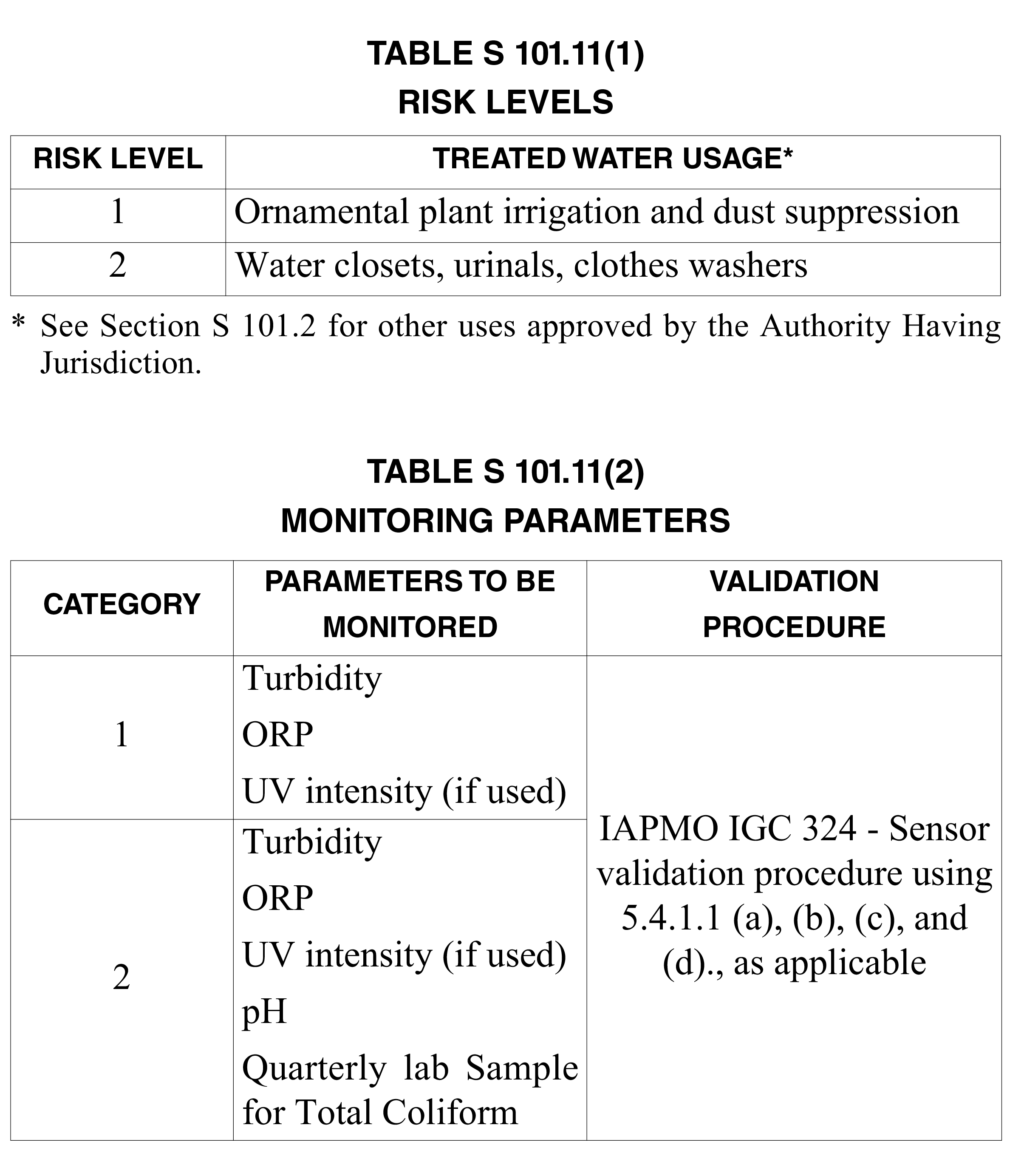

To add to the benefit of utilizing the Water Demand Calculator, Table C 303.3 was updated to include new fixture units for bathroom groups. The fixture unit values in Appendix C can be utilized, which leads to smaller pipe size.

(Table C 303.3 partly shown on following page)

New Product Standards Plumbing Product

Section 408.2 addresses tileable shower receptors. The PS 106 standard specifies requirements for materials, manufacture, physical characteristics, performance testing, and markings for prefabricated, tileable shower receptors; and tileable and pre-tiled shower kits that are field installed.

408.0 Showers.

408.2 Tileable Shower Receptors. Tileable shower receptors and shower kits shall comply with IAPMO PS 106.

Section 603.5.6 was updated to include IAPMO PS 72 as an option for backflow protection for lawn sprinkler valves. See image pictured to the right of a product compliant to IAPMO PS 72.

603.0 Cross-Connection Control.

603.5.6 Protection from Lawn Sprinklers and Irrigation Systems.

Potable water supplies to systems having no pumps or connections for pumping equipment, and no chemical injection or provisions for chemical injection, shall be protected from backflow by one of the following devices:

(1) Atmospheric vacuum breaker (AVB)

(2) Pressure vacuum breaker backflow prevention assembly (PVB)

(3) Spill-resistant pressure vacuum breaker (SVB)

(4) Reduced-pressure principle backflow prevention assembly (RP)

(5) A valve complying with IAPMO PS 72

Manifolds are utilized in water distribution systems. The addition of Section 606.5.1 for manifolds provides guidance to the end user and ensure that all components of field-installed manifolds conform the that applicable material standards for water distribution. The IAPMO IGC 109 covers water distribution manifolds for residential and commercial, hot and cold, water distribution systems, and specifies requirements for materials, physical characteristics, performance testing, and markings.

606.5.1 Manifolds. Field installed manifolds for water distribution shall conform with the applicable requirements for valves, pipes, and fittings as referenced in this code. Manufactured water distribution manifolds shall be in accordance with IAPMO IGC 109.

IAPMO has long published standards that address water-leaking detection products. The UPC was updated to include the latest reference standard for such technology. These standards are being used for the listing and certification of products designed to detect water leaks.

606.0 Valves.

606.9 Leak Detection Devices. Where leak detection devices for water supply and distribution are installed, they shall comply with IAPMO/ANSI Z1349.

Private Sewage Disposal System

The 1976 edition of the UPC first provided provisions for the safe installation of private sewage disposal systems. Under the ANSI-accredited development process since 2003, Appendix H (Private Sewage Disposal Systems) has been updated with the latest technologies and provisions. To clarify that private sewage disposal systems are addressed in Appendix H, Section 713.2 was revised to include reference to Appendix H for private sewage disposal systems.

713.2 Private Sewage Disposal System. Where no public sewer intended to serve a lot or premises is available in a thoroughfare or right of way abutting such lot or premises, drainage piping from a building or works shall be connected to a private sewage disposal system as approved by the Authority Having Jurisdiction. See Appendix H.

Improvements were further made to Appendix H as shown below:

H 301.0 Area of Disposal Fields and Seepage Pits.

H 301.1 General. The minimum effective absorption area in disposal fields in square feet (m2), and in seepage pits in square feet (m2) of sidewall, shall be predicated on the required septic tank capacity of gallons (liters), estimated waste/sewage flow rate, or whichever is greater, and shall be in accordance with Table H 201.1(2) as determined by the type of soil found in the excavation, and shall be as follows:

(1) – (5) (Not shown)

(6) Systems that combine treatment and disposal of sewage within a single footprint and comply with NSF 40 Class 1 shall be sized using a 0.70 multiplier applied to the required area in Table H 201.1(2) for both leach lines and leach beds. No system component for a combined treatment and disposal leach line or leach bed shall be located within 2 feet (610 mm) of the water table nor to a depth where sewage is capable of contaminating the underground water stratum that is usable for domestic purposes. Combined treatment and disposal system operation and maintenance shall be in accordance with the manufacturer’s instructions.

Exception: Combined treatment and disposal systems tested and certified in a bed configuration in accordance with NSF 40 Class 1 are exempted from the requirements of Section H 301.1(2).

H 501.0 Septic Tank Construction.

H 501.14 Prefabricated Septic Tanks.

Prefabricated septic tanks shall comply with the following requirements:

(1) Manufactured or prefabricated septic tanks shall comply with IAPMO/ANSI Z1000, IAPMO IGC 262, or CSA B66 and be approved by the Authority Having Jurisdiction. Prefabricated bituminous coated septic tanks shall comply with UL 70.

(2) Independent laboratory tests and engineering calculations certifying the tank capacity and structural stability shall be provided as required by the Authority Having Jurisdiction.

H 601.0 Disposal Fields.

H 601.1.1 Bundled Expanded Polystyrene Synthetic Aggregate Units. Bundled expanded polystyrene synthetic aggregate units with an integrated distribution line consisting of perforated, corrugated high-density polyethylene pipe that complies with IAPMO IGC 276 shall be permitted.

As you can see, Appendix H was enhanced to include the most updated and modern provisions regardless of the location. Appendix H is also available as a stand-alone option for jurisdictions to utilize, regardless of the adopted plumbing code.

Non-Sewered Sanitation

The forward thinking of the IAPMO technical committees cannot be emphasized enough. ANSI/CAN/IAPMO/ISO 30500, which was adopted into the United States and Canada as an identical adoption, helps develop new toilet technology that will save millions of lives. IAPMO takes pride in bringing this standard to these two nations, as the lack of safe sanitation is not only an issue in developing countries; there are reas in the United States and Canada that can benefit from the use of this standard. States like Hawaii or other areas where the use of cesspools is of concern, or California where droughts are common, can benefit from this technology, not to mention rural areas that lack safe sanitation.

The development of ANSI/CAN/IAPMO/ ISO 30500 led to the creation of Appendix O (Non-Sewered Sanitation Systems), which provides the necessary provisions for such systems. IAPMO encourages other standards developers to follow IAPMO’s lead and address similar technologies in their codes.

APPENDIX O

NON-SEWERED SANITATION SYSTEMS

(entire appendix not shown)

O 101.0 General.

O 101.1 Applicability. The provisions of this appendix shall apply to the installation of non-sewered sanitation systems.

O 101.2 System Requirements. Non-sewered sanitation systems shall comply with ANSI/CAN/IAPMO/ISO 30500.

Indoor Horticultural Facilities

Speaking of forward thinking, the 2021 UPC and UMC technical committees formed a Horticultural Task Group to develop provisions for facilities used to cultivate cannabis. The work of the task group led to the creation of Appendix Q, which applies to primary and secondary horticultural facilities. A primary horticulture facility is a facility devoted to the growing and/or harvesting of plants. Cultivation rooms are located within these facilities. A secondary horticulture facility is a facility devoted to harvesting (such as hulling /or shelling), packing, and/or holding of plants.

APPENDIX Q

INDOOR HORTICULTURAL FACILITIES

(entire appendix not shown)

Q 101.0 Indoor Horticultural Facilities.

Q 101.1 General. Plumbing for indoor horticulture facilities shall be in accordance with this code. This appendix shall apply to primary and secondary horticulture facilities.

Tiny Houses

An increase in construction of tiny houses has occured over the last couple of years. There is currently no guidance on the plumbing provisions for these systems. To address this need, Appendix R was created. This appendix removes the guesswork as to what provisions of the plumbing code apply to these structures. It is an easy-to-use appendix giving jurisdictions a go-to-guide for the proper plumbing provisions.

APPENDIX R

TINY HOUSES

(entire appendix not shown)

R 101.0 Tiny Houses.

R 101.1 Applicability. This appendix shall apply to structures permanently attached to a foundation. The tiny house plumbing systems shall be designed and installed in accordance with the requirements of this appendix and the requirements of this code. The provision of this appendix shall apply to permanent structures of 400 square feet (37 m2) or less. The provisions of this appendix shall not apply to recreational vehicles as defined in NFPA 1192 or to manufactured homes as defined in NFPA 501A.

Key Changes to the 2024 UMC

Geothermal District Systems

A modern mechanical code is one that is on the leading edge of the latest technology. When it comes to the latest and greatest, district geothermal is the part of that conversation. Imagine a world where every heat loss is captured for a beneficial use by another system, or where a community is taking advantage of the earth’s constant temperature. That is what is happening with a geothermal district system or an Ambient Temperature Loop (ATL). It is the latest technology on which many jurisdictions are capitalizing.

A district solution circulates water at ground temperature for efficiency and provides heat capture as decarbonization by sharing energy among building types in what becomes an “environmental neighborhood.” It introduces the fourth generation (4G) and fifth generation (5G) system configurations.

CHAPTER 17

GEOTHERMAL ENERGY SYSTEMS AND AMBIENT TEMPERATURE LOOPS

(entire appendix not shown)

Part V – Geothermal Ambient Temperature Loops (ATL).

1716.0 Ambient Temperature Loop (ATL) Distributed Energy Systems.

1716.1 General. An Ambient Temperature Loop (ATL) distributed energy system shall be installed in accordance with Section 1716.1.1 through Section 1716.6.3 and Section 1717.0. ATL systems shall comply with Part I through Part IV of this chapter, as applicable.

1716.1.1 Fourth Generation (4G) System Configuration. A fourth- generation system configuration shall

be a district geothermal energy system distributing hot water, cold water, or both to the conditioned space or building for a specific use. Where a geothermal energy source is used, such system shall comply with Part I through Part IV of this chapter, Chapter 11, and Chapter 12.

1716.1.2 Fifth Generation (5G) System Configurations. An advanced Ambient Temperature Loop (ATL) System or fifth generation (5G) ATL system shall also be capable of interacting with the electric utility system as well as other utility systems and systems components.

The system components shall include, but not limited to, the following:

(1) Thermally diverse buildings with independent hydronic systems

(2) Circulation loop

(3) Global control system

(4) Segment isolation capability

The system components may include, but not limited to, the following:

(1) Electric grid-interactive enabled buildings

(2) Hybrid components

(3) Other renewable systems

Indoor Horticultural

As stated earlier, the forward-thinking of the technical committee led to formation of a Horticultural Task Group to develop provisions for facilities used to cultivate cannabis. The work of the task group led to the creation of Appendix I in the UMC. The appendix has provisions for fire protection, documentation, carbon dioxide detection systems, flammable solvents, ventilation and exaust systems.

APPENDIX I

INDOOR HORTICULTURAL FACILITIES

(entire appendix not shown)

K 101.0 General.

K 101.1 Indoor Spaces. Indoor spaces using environmental controls for horticultural cultivation and processing of plants for human ingestion, inhalation, and topical application shall comply with this section.

Equipment and appliances shall be installed in accordance with the manufacturer’s installation instructions and this code. Piping, tubing, materials, and structures shall be protected in accordance with Section 316.0.

Low-Global Warming

Refrigerants

A major industry milestone was reached with the introduction of lower flammability refrigerants such as A2L and B2L. The industry’s concerns to address lower Global Warming Potential (GWP) refrigerants led to the development of these lower flammability refrigerants. UMC Chapter 11 does not only include these lower flammability refrigerants in Table 1102.3, but it also contains specific A2L and B2L provisions to address the precautions necessary for the proper use of these products. In particular, high-probability systems using A2L refrigerants for human comfort applications are covered by provisions that include refrigerant concentration limits, mechanical ventilation, ignition sources, compressors and pressure vessels, and refrigerant sensors. As with many provisions in the UPC and UMC, the 2021 edition of the UMC was the first mechanical code to include provisions for A2L and B2L systems as extracted from ASHRAE 15- 2019. Since then, ASHRAE 15 has published various addendums and many of the provisions found in the 2021 UMC required updating. Therefore, the provisions for human comfort and machinery rooms in the 2024 UMC were updated to be aligned with the latest published ASHRAE 15-2022 standard.

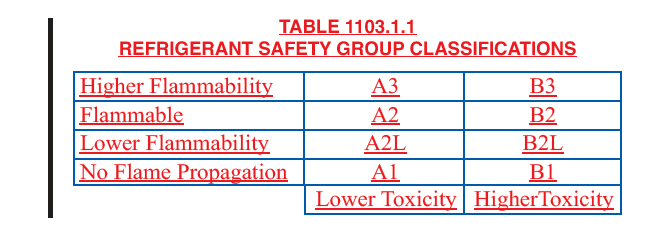

Table 1103.1.1 lists the classifications for the various refrigerants, including A2L and B2L. The human comfort applications in Section 1104.6 and the refrigerant room provisions were revised to align with ASHRAE 15.

1103.1.1 Safety Group. Table 1102.3 classifies refrigerants by toxicity and flammability, and assigns safety groups using combinations of toxicity class and flammability class. For the purposes of this chapter, the refrigerant Groups A1, A2L, A2, A3, B1, B2L, B2, and B3 shall be considered to be individual and distinct safety groups, as shown in Table 1103.1.1. Each refrigerant is assigned into not more than one group.

1104.6 Group A2L Refrigerants for Human Comfort.

1106.0 Refrigeration Machinery Rooms.

1106.2.9.1 Ventilation – A1, A2, A3, B1, B2 and B3 Refrigerants.

1106.11 Machinery Room, A2L and B2L.

Clean Air Delivery

The new Appendix J in the UMC provides safety provisions for the capability of the system, demand control ventilation, and performance requirements for carbon dioxide.

APPENDIX J

CLEAN AIR DELIVERY

(entire appendix not shown)

J 101.0 General.

J 101.1 Applicability. This appendix provides criteria for an increased protection level for occupant health by delivering and monitoring clean air in occupied areas of certain buildings. The provisions contained in this appendix are not mandatory unless specifically referenced in the adopting ordinance.

The 2027 UPC/UMC Revision Process is Underway

The IAPMO Standards Council has appointed the technical committees for the 2027 UPC/UMC development cycle. The deadline for submitting changes for the 2027 editions is Jan. 12, 2024. A 2027 UPC/UMC development timeline was made available to the public in 2022 and can be viewed on the IAPMO Codes website. The early publication of the UPC/UMC and timeline allows the public ample time to prepare and to review the changes in the code for any potential improvements.

Proposals can be submitted using the new IAPMO Codes Portal. No proposals will be accepted after January 12, 2024.

https://codeproposals.iapmo.org

What sets the IAPMO UPC/UMC ANSI- accredited development process apart from other plumbing and mechanical codes is the ample time the committee and the public is afforded to review the changes. This process allows the voice of the industry to be heard, allows for the same balance committee to review all proposals and comments submitted, and the opportunity to appeal to a third-party entity (ANSI).

Jurisdictions coast to coast already adopt the Uniform Codes, with others considering adoption. The public stands behind the Uniform Codes’ process and encourages local legislators to consider adoption of these modern codes.

Hugo Aguilar, P.E.

Last modified: May 8, 2024