A&J TRAINING TRUST’S NEW CAMPUS IN EL MONTE WANTS FOR LITTLE AS IT SEEKS TO EDUCATE 6,000 TRADESPEOPLE REPRESENTING SEVEN UA LOCALS

Walk into the Apprentice and Journeymen Training Trust’s new campus in El Monte, California, and it’s clear this isn’t just another school. The 9.5-acre site, with five buildings and more than 215,000 square feet of indoor training space, looks and feels like a hybrid between a college campus, a construction site, and a laboratory. Every classroom, lab, and training module is designed to move seamlessly from instruction to real-world practice, immersing apprentices and journey workers in the skills they will carry onto the job.

A&J CEO Preston Riehl and curriculum developer Ricardo Rios recently led Official on a tour of the sprawling campus. IAPMO Region 1A Field Manager Iggy Contreras, a part-time A&J instructor for 13 years before joining IAPMO in 2022, also participated in the tour.

The state-of-the-art facility serves seven United Association of Journeymen and Apprentices of the Plumbing and Pipefitting Industry of the United States and Canada (UA) Locals: 78 (Los Angeles), 250 (Gardena), 345 (Duarte), 364 (Colton), 398 (Rancho Cucamonga), 582 (Orange), and 761 (Burbank). Contreras explained that while A&J operates several other facilities across Southern California — including sites in Colton and San Diego, as well as smaller training centers focused on pipe fitting, welding and refrigeration — El Monte is now the largest and most comprehensive, replacing the former Compton location and moving administrative offices to the new facility. By consolidating both training and administration on one campus, it now serves as the flagship hub for A&J’s programs across the region.

Riehl estimated they have between 1,600 and 1,700 apprentices going through the five-year program, each of whom will receive six weeks of yearly training on campus. Additionally, the A&J’s roughly 4,300 journey workers have a requirement of 16 continuing education hours per year.

Designing the Vision

Riehl was the primary person responsible for the initial design of the new facility, working closely with Chief Financial Officer Devin Sanguansukdikosol. The first step was to finalize the architectural layout — delineating walls, restrooms, and other structural elements — before turning to the design and fine-tuning of the individual training spaces in collaboration with training coordinators and select staff. Once the drawings were complete, they were presented to and approved by the board. Throughout construction, Riehl and his team remained deeply engaged, visiting the site at least twice a week to provide input and ensure the project stayed aligned with the vision.

When asked how challenging it was to develop a wish list for what has become a state-of-the-art facility, Riehl said the process was “easier than you might think.” He said the team drew heavily on experience from the organization’s nine other training centers.

“At our other facilities, we’d often want to do something and couldn’t for one reason or another, or we’d think, ‘This would be better if …’ We made sure those lessons were built into El Monte.” While a few items had to be set aside for budget reasons, Riehl described the facility as “an illustration of all of our other training centers and our experiences with them over time.”

Classes began July 9, 2024, and administration moved in on Jan. 21, 2025.

Administration and Classrooms

The tour began in the administration building, which features conference rooms upstairs, including one that can accommodate more than 30 people — enough for their 26 trustees, lawyers, and A&J representatives. Riehl said their previous headquarters in Van Nuys had a room that was hardly more than a third as large.

“We had three- and four-hour meetings where it was standing room only, and it was kind of ridiculous,” Riehl said. A small room at the end of the conference area illustrates the attention to detail.

Separated by sliding frosted windows, it functions as a staging space for food or merchandise, ensuring meetings proceed without disruption.

“Even though it’s simple, that is the kind of thing that could change the tone of a meeting,” Riehl said, explaining that they expanded on a similar setup at an A&J facility in Santee, California.

Riehl said the previous conference room had a large marble table that, while beautiful, had 6-inch stainless steel legs and wasn’t easily moved, so the room’s setup was not easily altered. They kept that in mind while planning this facility. They also couldn’t bear to part with the table, which is now in the instructors’ break room.

“Pretty much everywhere — within our training modules, within our classrooms — everything is movable. Everything is module,” he said. “If we wanted to have eight rows in here and do something different, we could. That was a big key in the design, that we didn’t want to have any boat anchors anywhere.”

Downstairs are two classrooms that can accommodate up to 40 students.

“The primary intent behind those is that we teach all of our apprentices first aid and CPR, so it gives us a bigger room so we can perform the hands-on with the mannequins,” Riehl said.

The building also features an area with cubicles for each of the 15 full-time instructors. Riehl said previously, when teachers weren’t scheduled to teach but needed time to prepare, they were confined to their classrooms. This limited their ability to collaborate with supervisors, consult with the curriculum developer, or interact with each other.

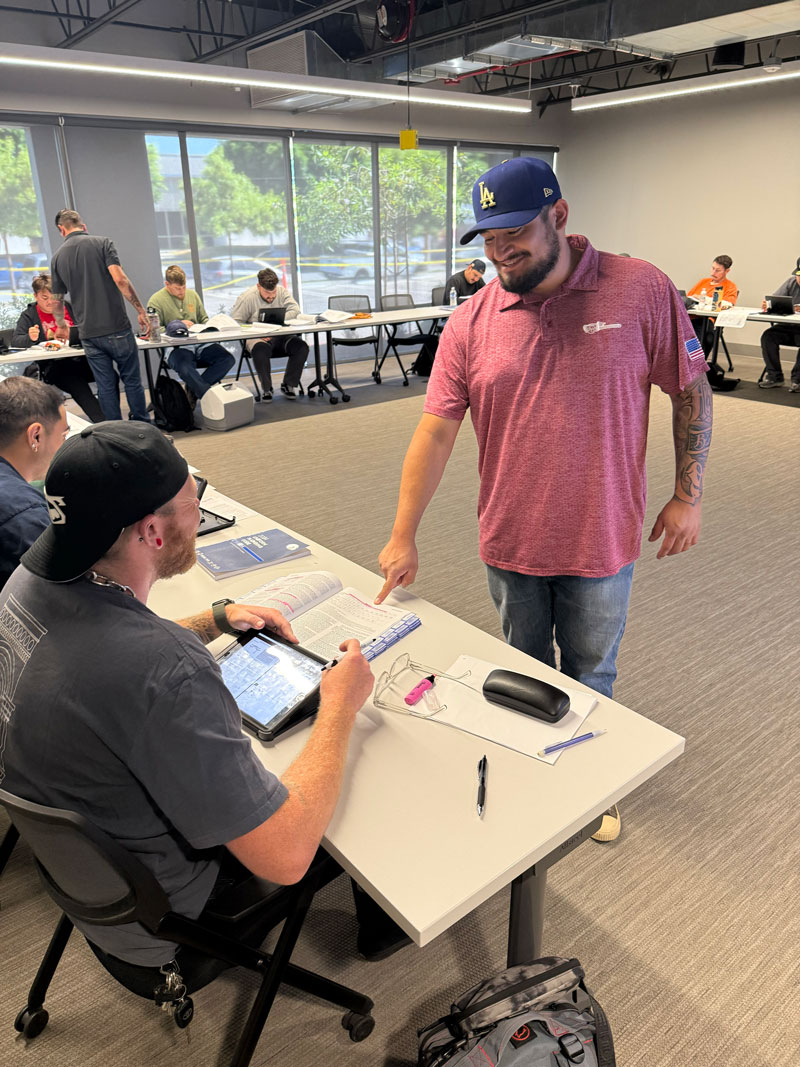

The tour continued to a separate building with 17 classrooms, including four computer labs where the monitors fold into the desks. Riehl said while the rooms are set up for 25 students per class, they try to limit them to 20. The standard setup is a U shape in which the students face each other with the instructor in the middle to increase interaction. The rooms are also equipped with a 96-inch touchscreen monitor, a video camera, speakers and a microphone for Zoom capability, as well as iPads with the Canvas learning management system for student use.

“When they come into the classroom each morning, they take an iPad from the charger and then all of their curriculum is pretty much based off that iPad, unless it’s something hands-on,” Riehl said.

With a goal of a 50/50 ratio of hands-on learning versus lecture, Riehl said the new facility provides the opportunity to get the students out of the classroom more.

“We are going back through the curriculum so we can implement a little bit more [hands-on training] now that we have somewhere to actually be able to do it in regard to the infrastructure,” he said.

In one of the computer labs, Riehl said other A&J training centers had computer labs whose setup made it impractical to use the room for anything else, even though they were only used four to six weeks per year.

“Even though this is kind of a cool and a little bit fancy, it was done to be more functional,” he said. “You could operate any class out of here as you would anywhere else.”

The A&J offers a post-apprenticeship computer-aided design (CAD) program that provides an introduction for those interested. Riehl said this typically prepares workers for detailing, which involves taking the job specifications and engineer’s drawings and turning them into installation drawings, as well as coordinating with the other trades.

“Coordinating with the other trades is probably the biggest one and the most time consuming,” he said. “If you weren’t worried about anybody else, you could draw it however you want. But then once everybody uploads their stuff to the model, you’ve got pipes running through ducts.”

Plumbing Modules

The plumbing building was next on the tour, beginning on the first level with 20 bays that contain stub-ups serving as drainage pipes and running to a sump tank. After performing their estimations, students work in pairs to install the systems, making the connections, roughing them out, and passing a rough test.

In a recent apprentice contest, participants were challenged not only to pass the rough test but also to install all of the fixtures — essentially creating a functioning restroom. The water from these systems is pumped overhead into a gray water system, which is then used to flush toilets in the core shell area for day-to-day operations.

“This is our residential rough-in,” Contreras said. “Upstairs would be the commercial-style rough-in. These are all something you see in a house or a hotel, all the fixtures. And then upstairs would be more of a commercial setting, office setting, whatever the case is.”

On the second floor of the modules area, Rios pointed to a plumbing wall where piping from the first floor continues upward, with students tasked to install a wall-hung water closet, urinal and lavatory.

“We can really be unique with how we do this training in this area because of how large it is, and all of our fixtures, materials and tools are in this area,” Rios said. “It doesn’t require us to travel outside of this location. A lot of planning was put into this. It is really smart how they laid it out.”

Students ultimately create fully operating bathrooms within about 38 hours. Rios emphasized that the focus is on skill as well as efficiency. To give the students a feel for leadership, one person from each crew is put in charge for the day, assigning tasks, tracking progress and even handling payroll. Apprentices also rotate through different roles to ensure everyone gains experience across all systems.

At the end of each cycle, students are required to dismantle the systems they’ve built. This not only resets the bays for the next group but also reinforces the full process of installation and removal. As part of the exercise, apprentices take inventory of all tools and materials used, ensuring accountability and preparing the area for the following week’s class.

Service & Standards

The service and repair area includes a wide range of equipment: commercial kitchen appliances, sinks, fuel gas units, and fixtures from residential, commercial, health care, and institutional settings — even prisons and hospitals. Along the back wall are additional heating appliances, including both tank and tankless water heaters, while a cluster of showers in the corner allows students to practice installation and repair.

To enhance training, plexiglass walls provide “X-ray vision” into the systems, giving apprentices a clear view of how fixtures are installed.

For many, it is the first time seeing this level of detail. Because apprentices often spend much of their early careers on a single type of project, their field experience can be limited. This space allows them to expand their exposure well beyond what they might normally encounter during their apprenticeship.

“A lot of these apprentices have never seen how the fixtures installed in the field because they’ve only been on a certain project that lasts almost their entire apprenticeship,” Rios said, “so they’ve only ever seen those types of fixtures that they’re installing. This is a great opportunity for them to see everything almost that exists.”

As part of the curriculum, apprentices are introduced to how standards are created and how they apply to each component of a piping system — from fixtures to distribution piping to supports and hangers. The goal is not for students to memorize every standard but to understand how each one relates to the specific component being installed.

“For example, thermostatic mixing valves — we kind of dive deep into that subject because there are so many different varieties out there and they’re attached to their own particular standard,” Rios explained. “The standards in our code books aren’t going to say you’re required to install a specific manufacturer’s valve. They’re going to say you’re required to install to ASSE 1069. Apprentices need to recognize what that standard requires and then identify which manufacturers produce products that meet it.”

The emphasis, he added, is not on memorizing product lists but on grasping what each standard demands and how to apply it in the field. The first floor of the service and repair area is dedicated to pumps, valves, and regulators. Here, apprentices work with three lift stations, as well as tanks, interceptors, and clarifiers. One lift station is positioned above ground to demonstrate that not all systems need to be buried; some can be located in mechanical rooms or other accessible spaces. Clear piping overhead illustrates how water travels through a system and how different tools function inside the lines.

During sewer cleaning classes, for example, apprentices run sewer cables and hydro-jetting nozzles, observing the spray patterns and comparing how each tool operates.

“We also have a clear plexiglass lid here so you can see inside the lift station,” Rios said. “In this class we’re teaching students how to remove all of the components of the pumps, pull them out of the lift station itself. In the field, pumps can get pretty big and we need to teach them how to do this safely and efficiently.”

The area also features live controls on the wall for hands-on practice. While no water enters the pit, the setup can be used for confined space training, giving apprentices the opportunity to learn proper entry techniques and safe handling practices for environments that may contain pathogens.

As the tour moved from the first floor of the service and repair area toward the medical gas training space, the group passed a demonstration service van donated by Milwaukee Tool.

Stocked with organizational equipment and tools, the van illustrates how contractors typically set up their vehicles for fieldwork.

“That van was part of their donation,” Rios explained. “We utilize it during our service and repair training. We show how a service van is typically set up.”

Medical Gas Training

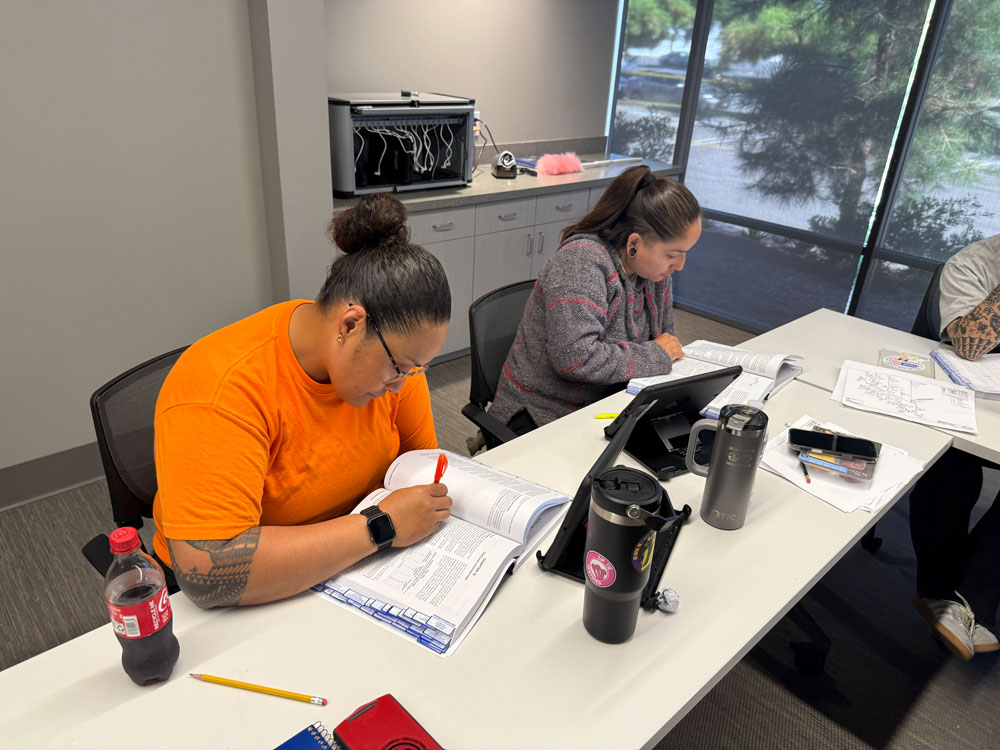

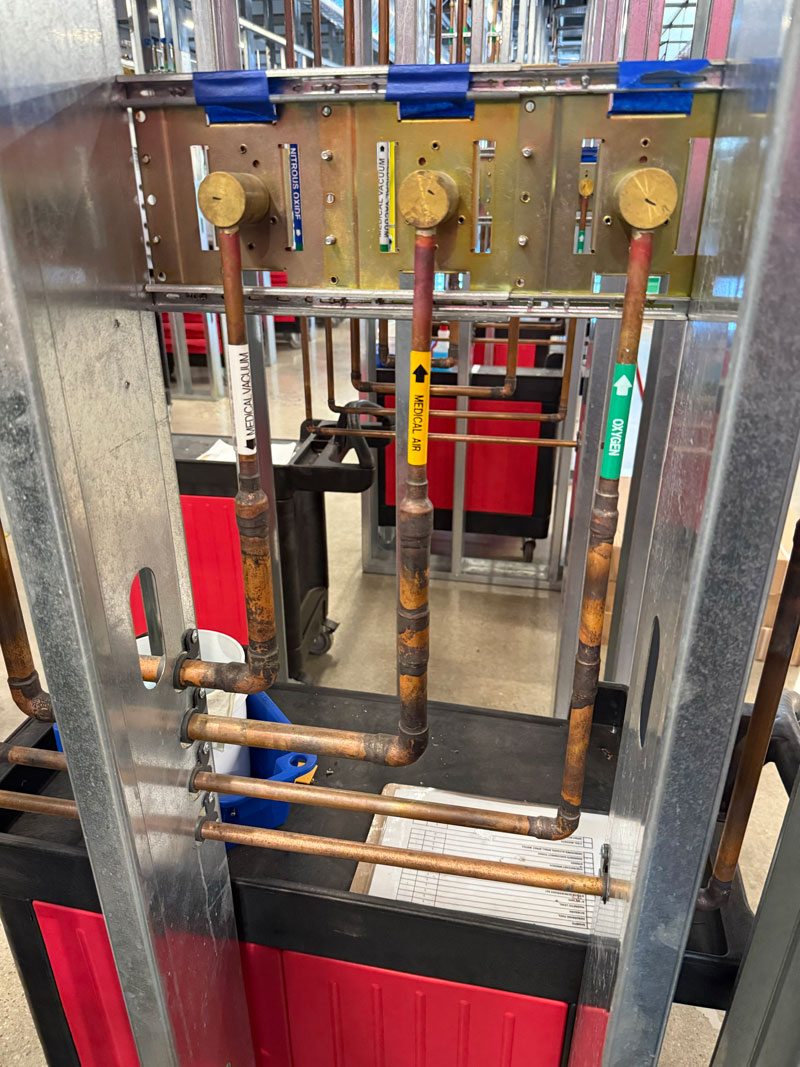

The next stop was the medical gas training area. Plumbing apprentices are required to complete 80 hours of training in this discipline: 40 hours of classroom instruction and 40 hours of hands-on installation.

While every plumbing apprentice receives medical gas training, completion does not guarantee certification. At the end of the code class, apprentices must pass both a competency assessment and a brazing test. In the brazing test, they must meet specific standards by demonstrating their ability on a test coupon and maintaining pressure in the system.

“We don’t want just anybody in the field installing piping that’s going to send oxygen to a young child,” Rios said. “We want to ensure these guys are capable and competent in that aspect of the industry.”

Unlike many training centers that offer only generic brazing stations, this area replicates real-world hospital conditions. Apprentices work on ladders, maneuver around obstacles, and install piping in configurations they’re likely to encounter in health care settings. Instructor Jaime Vera described the process in detail. Students must purge the inside of pipes with nitrogen while brazing to prevent oxidation and contamination.

“Patients go to hospitals because they’re ill and their immune system is down,” Vera said. “We don’t want anything in our piping system to have a negative impact on their health.” Apprentices also practice running gas and vacuum lines, installing service and zone valves, and connecting outlets — all while troubleshooting challenges designed into the mock hospital setup.

Vera said apprentices often spend extra time practicing on evenings or weekends to hone their brazing skills before advancing.

“By the time they get to their fifth year, this is the most challenging class they’ll take,” he said.

The medical gas program culminates with a national certification test.

For Vera, pride in the facility is personal.

“I got to design it, so I love it,” he said. “This was a dream of mine to have something like this. The students are just in awe. They realize how much of a resource they have here. They come to realize, ‘Before we get into that class, we’ve got to be prepared.’”

Water & Reuse

The water heating area features boilers, tank-type, and tankless water heaters, all connected and live-fired so apprentices could train on functioning equipment. Like much in the training facility, nothing in the room is for display only; every station is operational and available for hands-on practice.

Adjacent to this space is the wet lab, anchored by a large horseshoe-shaped stainless-steel sink where students dissect valves and fixtures under live pressure. The lab accommodates classes of about 20 students, rotating them among stations to gain experience with different fixtures. In addition to fixture repair, the space supports specialized lessons in backflow training, automatic control valve repair, and other areas of the curriculum requiring live pressure. The entire room operates like a giant shower, with water captured, contained, and recirculated.

Nearby is a water reclamation and rainwater catchment system. Developed with equipment from Water Harvesting Solutions (Wahaso), the system can simulate rainfall inside the building — capturing, filtering, conditioning, and reusing the water. Piping from the system, clearly identified in pink, distributes recycled water to fixtures throughout the plumbing building. The setup supports a 40-hour course focused on rainwater capture, treatment, and storm drainage, including references to the storm drain chapter in IAPMO’s Uniform Plumbing Code (UPC®).

The underground training area provides apprentices with hands-on instruction in sewer and storm drain piping, water distribution, fuel gas piping, and connections to fire suppression systems. Here, students learn to install large components such as grease interceptors, using an electric excavator to dig and set elevations without the risks of indoor emissions. Training continues regardless of weather conditions outside, ensuring apprentices didn’t miss upgrade opportunities that could affect their wages.

The space also includes a module for confined space training. Apprentices practice entering and working within confined areas, performing tasks, and exiting safely while wearing harnesses and respirators. The program emphasizes real-world safety, offering certifications for competent-person status in confined space operations. These courses are prioritized because of past industry incidents, reinforcing the importance of preventing similar accidents in the future.

After guiding the group through the administrative, classroom, plumbing, and service areas, Riehl stepped away and Rios continued leading the tour.

The dining hall features a micromarket with vending machines, and food trucks are often outside for additional options.

One hundred booths are located in this section for orbital welding training.

Advanced Training

The tour moved into the dining hall and auditorium building. The dining hall features a micromarket, essentially a walk-in vending area, where students can grab food and use microwaves for a hot meal. Just outside the doors, food trucks park during breaks and lunch periods, offering additional options.

The auditorium itself seats up to 300 people and is equipped for both large in-person trainings and hybrid virtual meetings. Outfitted with microphones and cameras throughout the space, it allows presenters to interact seamlessly with audiences both in the room and online. Contractors also use the hall for quarterly leadership meetings, pairing them with tours of the new training center.

The space additionally supports Journeyman Upgrade Training (JUT). Journeymen are required to complete 16 hours of continuing education annually, with hours due at the beginning of August. To help members meet the deadline, A&J often hosts expos in the auditorium that provide a final opportunity for journeymen to earn their required credits.

The tour continued into the 100-booth weld bay, divided between Miller and Lincoln machines so members gain experience with both systems. “The idea is to give our members the opportunity to be well-rounded on both machines and their small differences,” Rios said. The bay is open for walk-in practice, where apprentices can simply sign in, grab two pieces of metal, and “burn rod” on a walk-in basis.

Next is the orbital welding room, which replicates the clean-room conditions often found in laboratory or health care projects.

“Orbital welding is a process that is performed essentially by a program or a machine that the member builds and uploads into the machine so that it can perform the weld to that specific size, height or application process, or standard,” Rios said.

The brazing area is also open for walk-in use, providing a controlled environment with exhaust extraction where apprentices learn soldering and brazing early in their training. Rios said they utilize the stations to teach apprentices how to solder and braze for the first time in their apprenticeship. Larger stations accommodate 6- to 8-inch pipe, where apprentices must demonstrate competency before working on similar systems in the field.

Rigging and crane signaling are taught in a nearby open space, where apprentices begin with pipe-joining fundamentals and safe load transfer.

“This is one of the hardest certs to get, in my opinion,” Contreras said.

Apprentices learn how to calculate weight distribution and use cranes or hoists to move large equipment.

“We’re almost balancing this thing in the air, and it’s not just something that is equal in weight distribution,” Rios said. “We could be picking up an appliance or a large boiler where it’s heavier on one side than it is another, but it’s in a square container so from the outside it looks like it’s equal weight, but the weight is actually shifted to one side or another.”

All apprentices complete an awareness course in rigging, and certification is required to perform rigging or crane signaling. As Contreras pointed out, there is a prerequisite before they even begin the process to make sure they have the necessary math skills to perform the tasks.

“You have to provide documentation that you’re certified,” Rios said. “They’re not even going to pretend that you’re experienced to do it if you’re not holding a certification, and the liability is astronomical if an even happens.”

The facility also features a valve repair certification area, where apprentices learn to service valves that are welded in place and used to control volatile fluids. Nearby modules focus on safe bolting and pressure testing, preparing apprentices for steam and high-pressure systems. Apprentices also install steam piping from supply and return lines to fixtures such as fan coil units, supported by a live flame-tube boiler.

On the second floor, apprentices pursuing the instrumentation track begin with fundamentals like electricity, tube bending, and the math needed to align multiple runs of tubing. Advanced classes cover service and repair, component sizing, and diagnostics.

The equipment and components in the building are typically powered by alternative energy sources rather than being operated manually.

“These components are operated by compressed air,” he said. “For example, an oil refinery, we wouldn’t want a valve to be controlled by electricity. We would want low-voltage communication of what’s happening on that valve — like positioning and maybe the fact that it’s operating — but also we want to use something like an inert gas to control the function of the valve to prevent any sparks or prevent any kind of a catastrophic failure.”

Built for the Future

From its flexible classrooms and medical gas labs to its weld bays, rigging areas, and instrumentation rooms, every corner of the El Monte facility reflects careful planning and a commitment to hands-on learning. Nothing is for show — everything is designed to be used, tested, and practiced. The result is a state-of-the-art campus built not just for training, but for shaping the next generation of industry leaders.

Mike Flenniken is a staff writer, Marketing and Communications, for IAPMO. Prior to joining IAPMO in 2010, Flenniken worked in public relations for a group of Southern California hospitals and as a journalist in writing and editing capacities for various Southern California daily newspapers.

Last modified: November 3, 2025