When Gregg Holladay stepped to the podium at IAPMO’s Annual Education and Business Conference, he got right to the point about a coming shift that will affect every plumbing inspector and installer in the industry: under new U.S. Department of Energy standards taking effect in 2029, manufacturers will no longer be allowed to produce residential standard electric water heaters larger than 35 gallons.

The mandate will usher in a nationwide transition to heat pump water heaters, a technology that uses a fraction of the energy of traditional models and is poised to redefine residential water heating in the United States. This directly affects about 50% of American homes that already have electric water heaters, not to mention those who might fuel switch from gas to electric heat pump water heaters which is encouraged in some states like California.

Holladay, business development manager for specialty markets at Bradford White, said his mission wasn’t to sell a product but to prepare the industry for a fundamental shift.

Gregg Holladay, business development manager for specialty markets at Bradford White, delivers a presentation at IAPMO’s annual Education and Business Conference. He said his mission was to prepare the industry for moving away from standard electric water heaters larger than 35 gallons.

PHOTO BY BRIAN GADBERY

“All of the other manufacturers know that I’m here to help further the industry and the partnership that we have with you as instructors and installers for heat pump water heaters,” he said. “The industry is about to change and it’s going to affect everybody equally.”

He began with the basics.

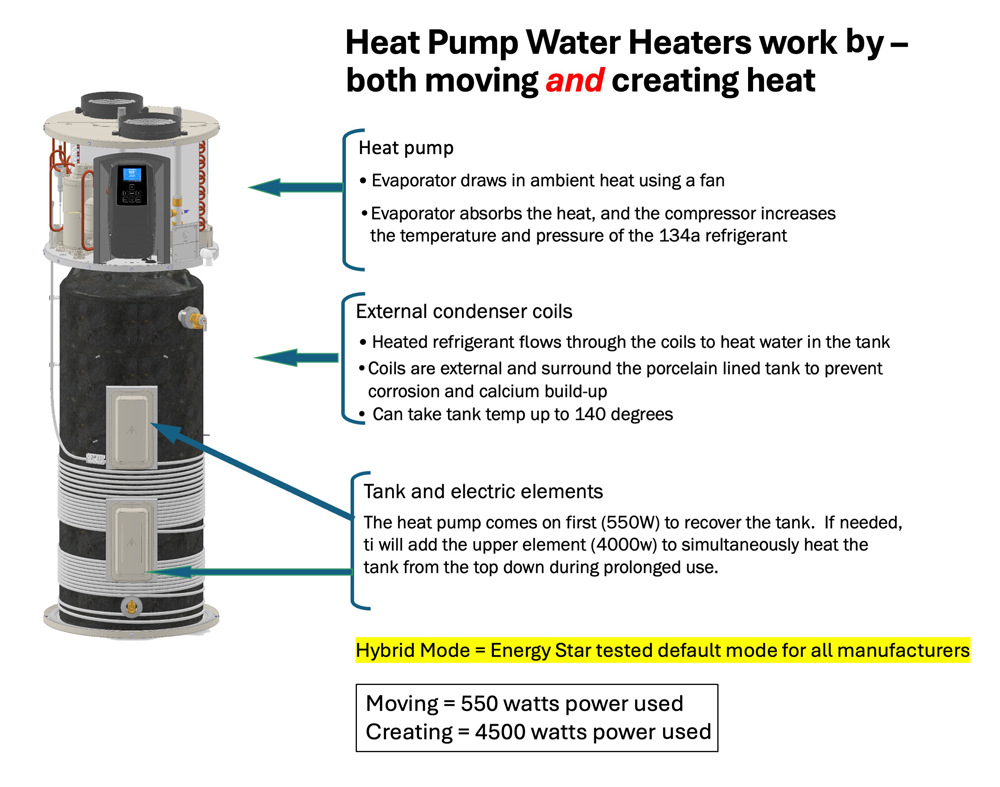

“Did you know a refrigerator’s a heat pump?” Holladay asked. “It says, ‘You put something hot inside, and my job is to move that heat from inside to outside.’”

Heat pump water heaters operate the same way — by transferring heat rather than creating it.

“Heat pump water heaters absolutely work,” he said. “They deliver on two promises: same volume of water, same recovery, but it delivers on the second promise, which is about a 75% reduction in the cost of operation.”

Compared with conventional electric units that operate at roughly 90 to 93% efficiency, Holladay said a 65-gallon heat pump model can reach about 420% efficiency.

“That means you spend a dollar to heat water, and you get $4.20 in hot water,” he said.

“If I’ve got a water heater that saves you about 400 bucks a year and it has a 10-year warranty, that’s about $4,000 you don’t pay the power company,” he added. “The water heater pays for itself by definition; no other water heater has ever been able to do that.”

Holladay reminded the audience that the federal tax credit — a 30% deduction of the installed cost, up to $2,000 — remains available through the end of 2025. But the bigger deadline is 2029.

“In just three and a half years, every manufacturer has to cease manufacturing residential electric water heaters as you know them today above 35 gallons,” he said. “All of a sudden water heaters will be replaced with heat pump water heaters.”

Holladay said many contractors hesitate to embrace heat pump technology until they understand the financial benefits of encouraging homeowners to replace aging units early. Once people realize how much money they lose each year on energy costs, he said, they are far more willing to switch.

He also warned that unprepared installers will create inspection problems when heat pump models become the only option available.

“There will be contractors out there that said, ‘I don’t want to learn about that’ until the day they walk up to a counter and that’s all they can buy to replace an electric water heater,” he said. “Do you think they’re going to read the instructions? No. They’re going to just put it in like they did every water heater they had before, and your life is going to get turned upside down.”

He added that some installers will place units in closets without realizing the need for proper airflow. Heat pump water heaters require air movement like a refrigerator.

“It’s got to move air around, heat around, and it needs some way of dissipating that,” he said. “My efforts are purely on trying to prepare the industry and make everybody ready so that you can help educate contractors with us as manufacturers in the home,” Holladay said.

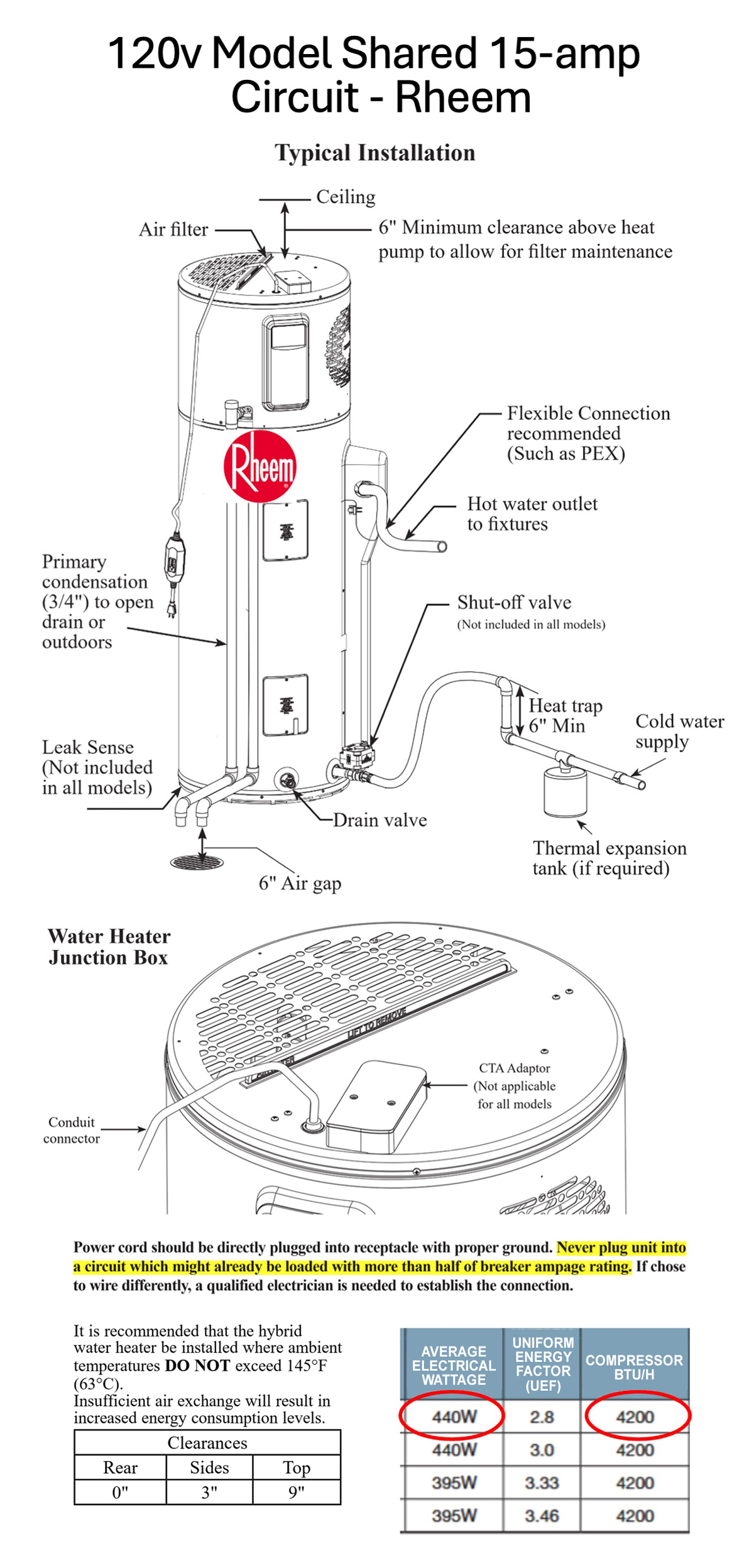

INSTALLATION BASICS

Manufacturers commonly recommend about 7 inches of clearance around the unit. Holladay said this space isn’t a strict requirement but is strongly advised because it provides enough room for servicing the heater — including removing the top if repairs are needed — and makes future maintenance much easier.

“Don’t just shove it against the wall because you can,” he said, “but that doesn’t mean that it’s improperly installed.”

He emphasized that clearances vary by manufacturer and model, and inspectors should be familiar with each unit’s specific requirements.

“Understanding the product is the key to being able to recognize proper installation — the things that can make a difference that you should flag and things that don’t make a difference, that you shouldn’t flag.”

OPERATION NOTES

“Heat pump water heaters naturally dehumidify, and they’re going to take out about 2 quarts of moisture a day,” Holladay said. Their condensate is non-acidic, he added, and may share a drain with an HVAC system as long as the line does not terminate in the water heater’s drain pan.

He also reminded attendees that noise is not a concern.

“Every heat pump water heater is less than 50 decibels in sound,” he said. “Sound is nothing you’re ever going to fail one on.” Location flexibility remains similar to traditional electric units.

“Any place that a water heater exists today that the pipes aren’t freezing, a heat pump water heater will work,” Holladay said, adding that while it may rely more on backup electric elements in cold weather, the overall savings remain significant.

Efficiency Tips

For homes converting from gas to electric, Holladay encouraged raising the tank’s temperature setting. Heat pump water heaters are shipped at 120 degrees Fahrenheit because manufacturers are legally required to do so, but that setting isn’t intended to remain fixed. Higher temperatures can help extend the available hot-water supply, especially for larger families, and California requires tempering temperature limiting valves to protect the public from scalding and shock at the point of use.

Increasing the set point to around 140oF helps offset the slower recovery rate of electric systems compared to gas, he said, giving households a buffer of additional stored heat while still maintaining safe delivery temperatures through properly installed mixing valves.

He discouraged constant hot-water recirculation systems where possible.

“Recirc systems need to be smart,” he said. “They don’t need to run continuously, and they need to run when you need to do one thing, and that’s take a shower in the morning.”

Smart Recirculation Example

Holladay also shared a personal example of how on-demand recirculation can improve efficiency and comfort. A California company, ACT, once approached him after hearing him speak about smart recirculation at a contractor event. They offered to let him test one of their Bluetooth-activated systems, assuring him they wanted only his honest feedback. He agreed — and later installed the system in his own home.

He placed the small wireless button at the end of the sink and cabinets in one of their bathrooms, where it could be pressed before using hot water. He told his wife to make a habit of pressing the button each morning. Within about 20 seconds, the pump runs quietly beneath the floor, and the shower is ready with instant hot water.

“She loves it,” he said. “Anybody that puts one in will never go back.”

He also pointed out another personal example for simple installation details that can prevent future problems.

“Condensate drains should have a T; they’re not required,” he said, but noted that using a T-fitting makes clearing a clog far easier than cutting out an elbow.

Safety and Service

Holladay said some manufacturers are beginning to use new refrigerants, including mildly flammable blends. While he did not take a position on the refrigerant used, he noted that these models include additional warnings and handling considerations of which installers need to be aware.

“This raises a lot of questions,” he said. “I’m not going to try to editorialize on it. I’m just going to present this information.”

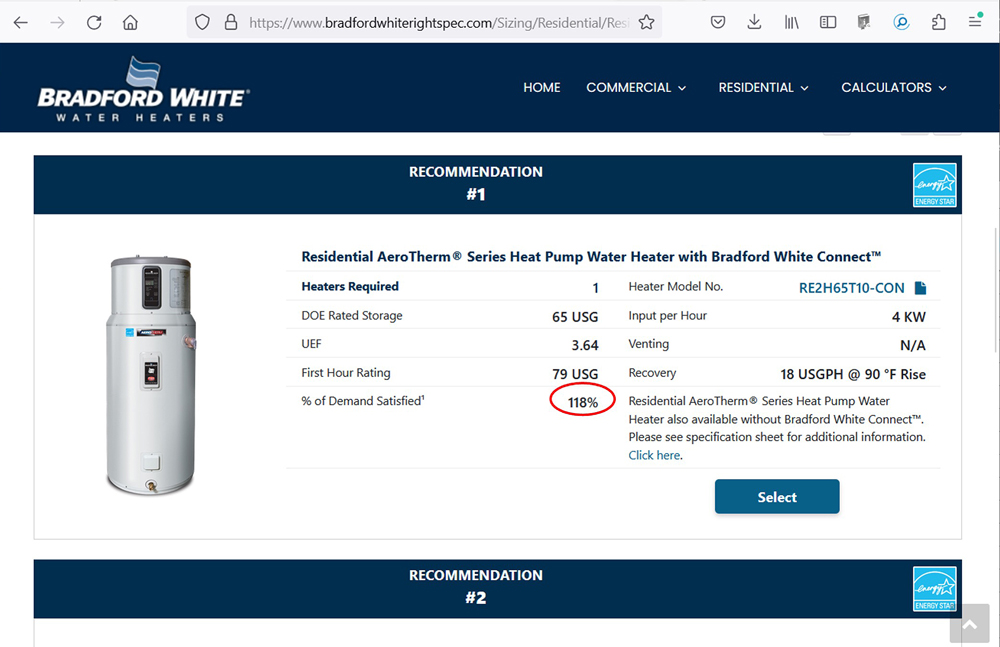

Holladay also pointed out a major difference in how various brands are built. Some heat pump water heaters are designed in a way that requires full unit replacement if sealed system components fail. The Bradford White AeroTherm, he said, is fully serviceable — meaning individual parts, including the sealed system, can be repaired or replaced without discarding the entire water heater. That distinction can significantly reduce long-term costs for homeowners and reduce waste at the end of the product’s life.

Even during power outages, the units remain practical.

As he spoke, Holladay pointed to the demonstration unit he had brought to the front of the room, using it to illustrate how little power the system requires. “This uses 500 watts of power,” he said. “I can have hot water and use the same amount of power that’s in a refrigerator to make that happen.”

com/Sizing/ | IMAGE SOURCED FROM INSTRUCTOR’S ORIGINAL PRESENTATION

Sizing and Training

Correct sizing remains essential. Bradford White’s product-selection app helps contractors choose the right model based on bedrooms, bathrooms, and overall demand. “You have to size it right,” he said. “Nobody ever complained about having too much hot water, have they? No. Bigger is always better.” Throughout his presentation, Holladay returned to one central message: read the installation instructions and help others do the same.

“Read the book — every page,” he said. “Don’t assume that you know anything about heat pump water heaters because you probably don’t.”

He encouraged inspectors and installers to work closely with manufacturers as the transition accelerates.

“Partner with the manufacturer, ask questions, get clarity, learn from us,” he said. “Help the installer learn and gain valuable experience. In some cases, you could be the best teacher.”

His final instruction was simple — and timely: “Get ready to see a lot of these.”

Mike Flenniken is a staff writer, Marketing and Communications, for IAPMO. Prior to joining IAPMO in 2010, Flenniken worked in public relations for a group of Southern California hospitals and as a journalist in writing and editing capacities for various Southern California daily newspapers.

Last modified: February 19, 2026