FIRE HYDRANTS HAVE LOOKED — AND WORKED RELIABLY — THE SAME FOR 100 YEARS, BUT IS IT TIME TO CONSIDER UPDATES FOR THE 21ST CENTURY?

There are perhaps two images that a fire hydrant can immediately conjure in popular imagination. One is in its intended life-saving capacity. In the other, over- heated kids pry one open to flood a city street on a broiling summer day. The failure of a fire hydrant can make a community vulnerable.

“For better or worse, the fire hydrant has looked the same for 100 years,” says Robin Zevotek, principal engineer for the National Fire Protection Association (NFPA), noting that the first patents for fire hydrants date back to the 1850s. Given that, it is perhaps not surprising that methods to innovate the fire hydrant are being sought. “It’s technology that’s ripe for innovation,” Zevotek says.

Venkatesh Kodur, a Professor in Michigan State University’s College of Engineering states that hydrants are the “backbone for the first responders,” noting that hydrants assist fire departments in routinely dispatching millions of fires annually. He says that the optimal window to respond to a fire is within the first 10 to 15 minutes.

“Lose control and the whole neighborhood could be gone.” Kodur says, adding, “When the fires go beyond and a whole neighborhood is on fire, or a factory, these hydrants aren’t made for that.”

When a hydrant fails, it can become the lead story on the local news station or even receive national coverage. A Jan. 24 story in the New York Times warned, “Wildfires are Revealing the Limits of Our Hydrant Systems.” In 2024, West Virginia’s WCHS News spoke to West Virginian resident Jeffrey Harris, who watched a historic home on his street burn to the ground as firefighters worked the scene without the ability to spray water from the nearby hydrant. “You kind of feel secure knowing that there’s a fire hydrant just two houses away from you,” Harris told the news team. “To find out that it’s not working is just kind of a gut punch.”

Stories like this sparked an investigation from the West Virginia Public Service Commission. Prior to its work, there was no standard authority in West Virginia for the inspecting of fire hydrants. WHCS reported that the report, “found that aging fire hydrants in West Virginia aren’t being tested or replaced quick enough.”

Are Fire Hydrant Failures Picking Up?

It seems to Zevotek that whenever there’s a high-profile fire where a hydrant fails, he gets calls asking if this is a trend. “It’s a very effective system,” he says, noting that the number of fires successfully suppressed in part thanks to the availability of working hydrants often goes unheralded and that he has seen no data set to suggest that failures are becoming endemic. Even still, he acknowledges that with thousands of hydrants placed around the country, “there’s a potential that as these systems age, we might see more failure,” adding, “The consequences when failure does happen can be huge.”

As Chairman of the task force that conducted the state investigation of the fire hydrant stock in West Virginia, Jim Ellars was heartened by the broad response the state review received from its initial questionnaire, which intended to see if uniform inspection best practices existed across the multiple utilities. Ellars and his peers spoke with municipal agencies, fire marshalls, and volunteer and paid fire fighters. When asked if fire hydrant failure was systemic, Ellars unequivocally asserted, “I wouldn’t say systemic, no,” but he did report that of the utilities with which he spoke, only 42% had a written inspection procedure in place while 73% reported an annual inspection plan. Fire hydrants, he found, had a 68-year replacement cycle, meaning that West Virginia had “some very old hydrants.”

Age isn’t the only vulnerability. Kodur noted that more than 300 hydrants were stolen in 2024.

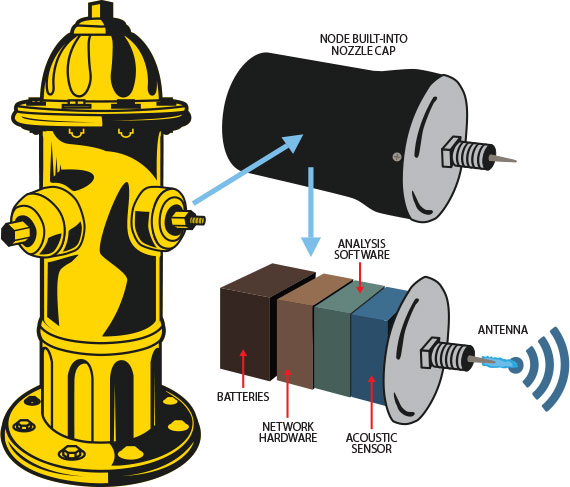

EchoShore® – DX nodes are embedded in a standard fire hydrant cap, which provides leak detection technology to create a wireless monitoring network.

SOURCE INFORMATION COURTESY OF ECHOLOGICS. GRAPHIC BY JEFF ORTIZ

How Do You Keep Up with Thousands of Hydrants?

“The problem is how to proactively ensure the good working order of a system that needs to be mechanically tested,” Zevotek says. “NFPA gives pretty specific guidance on annually inspecting hydrants.”

Ellars concurs, reporting that, “Our solution in our rules was to establish annual inspections and periodic flow testing and marking them.”

However, with drought conditions becoming of increasing concern in many parts of the country, it is harder to defend the idea that the only way to properly inspect a hydrant is flowing water through it to see if the stem, bolts, and caps are all in place with proper lubrication. Because of the tension between the value of inspecting hydrants and the hazard of wasting water, Zevotek has seen multiple municipalities put the hydrants on a testing schedule, with redundancy back-up plans in place that call for a second truck to approach from a fresh angle, adjacent to a slightly farther second hydrant.

“We need to rethink our strategies,” Kodur says. He believes that AI, machine learning, and drone technologies could greatly facilitate the work of visual inspections, helping municipalities with scarce resources prioritize an inspection schedule and more quickly fixing faulty hydrants that have been damaged or stolen.

Mueller markets a potential time and money saving solution. Product Manager Asha Budhlall says that their Echologic’s monitoring technology helps utilities find leaks in the system, using acoustic technology to listen to the lines at the quietest times of day — more specifically the middle of the night, around 2 a.m.

“You don’t have to send field operators out to survey until there is a scientifically qualified potential leak,” says Budhlall. “The system is listening while you’re sleeping.”

The technology can locate hydrant leaks, or other critical leaks, such as an underground leak that might never be visible on the surface but carries detrimental impacts ranging from water loss, inefficiency of the hydrant, and wasting water that’s already been treated, essentially wasting the prowess of the utility’s water treatment.

The product is built into nozzle caps for ease of installation. Asha cites a number of factors — lower head counts at utilities, reduced budgets, inflationary pressures resulting in fewer resources — where this adaptation can have a critical benefit.

While not the primary intention of the Echologics system, it can help a utility more quickly identify hydrants that have been stolen or tampered with, flagging some units primed for inspection because they may have been opened or closed inappropriately.

While the monitoring devices do not provide condition assessment, Mueller continues to develop ways to extract deeper insights from their emergent technology.

It remains to be seen how much human touch can be subtracted from the process. When asked how much of those inspections could be automated or that a technological solution could be employed, Ellars was skeptical. “You’ve got to have people on the ground,” he says. “You’ve got to go out and do it at the hydrant.”

Matt Chapuran

Last modified: November 3, 2025