October 16, 2025

From the 2024 UPC Illustrated Training Manual, Chapter 3, GENERAL REGULATIONS

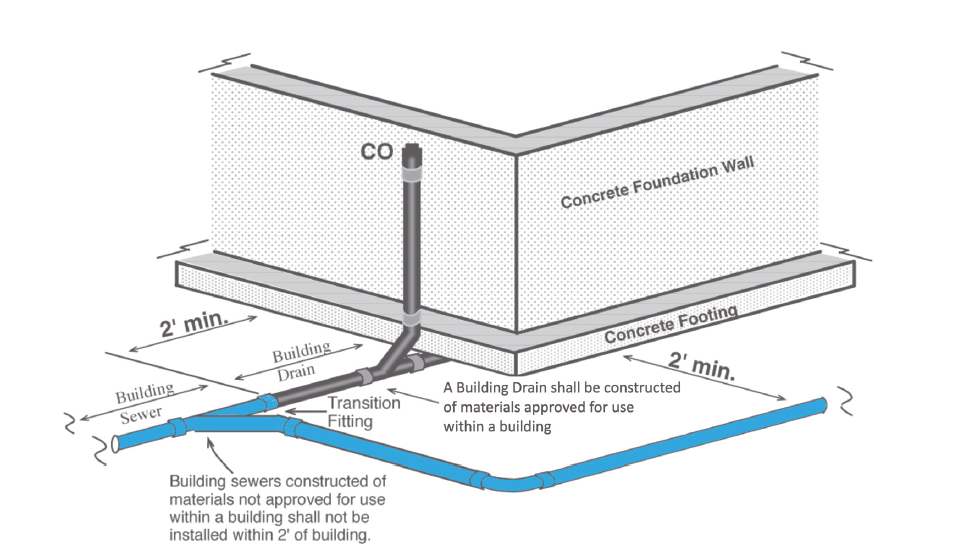

312.3 Building Sewer and Drainage Piping. No building sewer or other drainage piping or part thereof, constructed of materials other than those approved for use under or within a building, shall be installed under or within 2 feet (610 mm) of a building or structure, or less than 1 foot (305 mm) below the surface of the ground.

The standard for a piping material will define its use for either within the building (the building drain) or outside the building or structural slab (the sewer or building sewer). Materials that may be used under the building will be strong enough to withstand the settlement or weight of the building. Piping materials such as cast iron and Schedule 40 PVC or ABS may be used for the building drain. Figure 312.3 illustrates this requirement.

Sewers consisting of materials for use only outside of the building or structure, such as PVC SDR 35 or clay pipe, must be installed a minimum of two feet from the building or structure and one foot below grade. In this manner the piping will be protected from damage due to the building weight or settlement. If damage is likely to occur, vertical piping must also be protected.

CLEARANCES FOR PIPING MATERIALS USED FOR BUILDING DRAIN AND BUILDING SEWERS

From the 2024 UMC Illustrated Training Manual, Chapter 3, GENERAL REGULATIONS

310.5 Point of Discharge. Air-conditioning condensate waste pipes shall connect indirectly to the drainage system through an air gap or air break to trapped and vented receptors, dry wells, mop sinks, leach pits, or the tailpiece of plumbing fixtures. An individual condensate drain shall be trapped in accordance with the appliance manufacturer’s instructions or in accordance with Section 310.4.

Since many air moving appliances have different negative pressure drops across the cooling coil it is important to use the manufacture’s recommendation on trap sizing. A properly functioning and designed condensate trap provides for discharge of water from the cooling coil drain pan, while the water seal (the water level maintained in the trap) prevents the flow of ambient air into or out of the air handler. Several problems result from improperly trapped systems, some of which can severely impact indoor air quality. Where a trap is improperly installed or designed, an incoming air stream may be introduced through the drain and the air flowing through the coil can possibly spray condensate into the fan intake, which can propel the moisture into other parts of the system; which can then be carried through the ducts and into the conditioned space possibly causing bacterial growth and transmission. Furthermore, improperly trapped systems can include the trap outlet is too short or the trap outlet is too tall, or other potential incorrect sizing. The manufacturer of the appliance typically provides trapping requirements that should be followed when sizing the condensate drainage trap.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: October 16, 2025