November 21, 2024

From the 2024 UPC Illustrated Training Manual, Chapter 11 – STORM DRAINAGE

1101.6.1 Discharge. Subsoil drains shall be piped to a storm drain, to an approved water course, to the front street curb or gutter, to an alley, or the discharge from the subsoil drains shall be conveyed to the alley by a concrete gutter. Where a continuously flowing spring or groundwater is encountered, subsoil drains shall be piped to a storm drain or an approved water course.

As with storm water systems, the subsoil water must be removed without causing a nuisance. It must be piped to a naturally draining waterway or the area surrounding the building must be designed to carry the storm water using a method such as guttering in a parking lot as in Figure 1101.6.1. It should never be allowed to run across a sidewalk or walkway but drain to a curb or gutter. If the water is continuously flowing, then it should be piped to a storm drain or waterway rather than constantly running over open and traveled areas.

CONCRETE CONDUIT OR GUTTER

From the 2024 UMC Illustrated Training Manual, Chapter 8 – CHIMNEYS AND VENTS

802.5.5 Size of Chimneys. The effective area of a chimney venting system serving listed appliances with draft hoods, Category I appliances, and other appliances listed for use with Type B vents shall be in accordance with one of the following methods:

(1) Those listed in Section 803.0.

(2) The effective areas of the vent connector and chimney flue of a venting system serving a single appliance with a draft hood shall be not less than the area of the appliance flue collar or draft hood outlet or greater than seven times the draft hood outlet area.

(3) The effective area of the chimney flue of a venting system serving two appliances with draft hoods shall be not less than the area of the larger draft hood outlet plus 50 percent of the area of the smaller draft hood outlet or greater than seven times the smaller draft hood outlet area.

(4) Chimney venting systems using mechanical draft shall be sized in accordance with engineering methods.

(5) Other engineering methods. [NFPA 54:12.6.3.1]

Information on the sizing of chimneys is also provided in Section 803.0 in the form of tables and additional requirements. These venting requirements were developed by a research project funded by the Gas Research Institute and conducted by Battelle.

The requirements in Section 803.0 recognize that there is a significant difference between the operation of interior and exterior chimneys. An exterior chimney has one or more sides exposed to the outdoors below the roof line. An interior chimney is not exposed to the outdoors below the building’s roof line. (Chimneys that pass through unheated attics or garages are not considered to be outdoors.) An interior chimney is largely isolated from weather changes. An exterior chimney is affected by the outside ambient temperature. Therefore, the requirements for exterior chimneys are keyed to the lowest temperature expected in different parts of the country.

The requirements for sizing chimneys were developed using a flue loss of 17 percent for the heating appliance. Most real furnaces and boilers operate at a higher flue loss; therefore, the code requirements are conservative. Several manufacturers offer customized vent kits, which include venting requirements for masonry chimneys keyed to the exact performance of their appliances. In this case, their recommendations should be used.

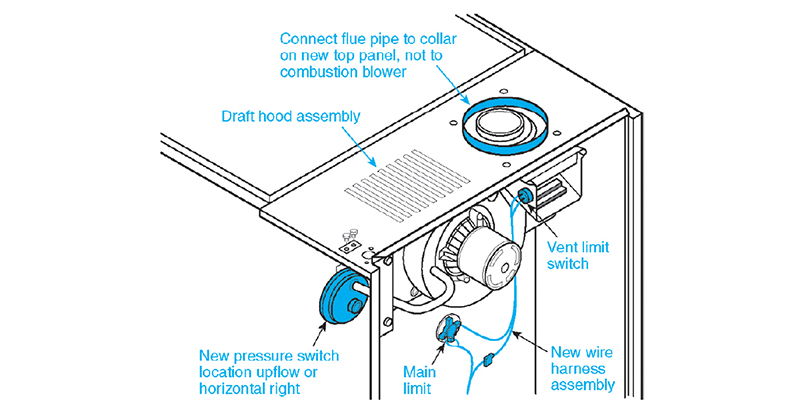

CUSTOMIZED VENT KIT

Figure 802.5.5 shows an example of a custom vent kit. The figure illustrates a furnace with a field-installed modification utilizing customized venting instructions for venting using a masonry chimney. Note the draft hood to the right of the induced draft blower, which has been added. The kit includes the hardware and venting instructions.

The sizing methods in Sections 802.5.5(2) and 802.5.5(3) permit a simple, alternative, chimney-sizing method that limits the vent to a maximum size of 7 times the smallest draft hood outlet area and a minimum size based on the draft hood outlet area. These methods limit the maximum size of the vent connector and gas vent to minimize condensation in the gas vent caused by insufficient flow of hot vent gases to heat an excessively large gas vent. Excessive condensation can cause premature failure of a chimney.

Note that Section 802.5.5(3) limits the use of this alternative to chimney venting systems serving only two appliances. Sample calculations using the venting tables in Section 803.0 and the alternative method showed that the alternative method results in vent sizes too small when four or more appliances are involved, and for some tall vents. The alternate always provides acceptable vent sizes for two appliances. Venting systems serving more than two appliances must use the vent sizing tables in Section 803.0 or other engineering methods.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: November 21, 2024