November 14, 2024

From the 2024 UPC Illustrated Training Manual, Chapter 3 – GENERAL REGULATIONS

306.0 Industrial Wastes.

306.1 Detrimental Wastes. Wastes detrimental to the public sewer system or detrimental to the functioning of the sewage treatment plant shall be treated and disposed of as found necessary and directed by the Authority Having Jurisdiction.

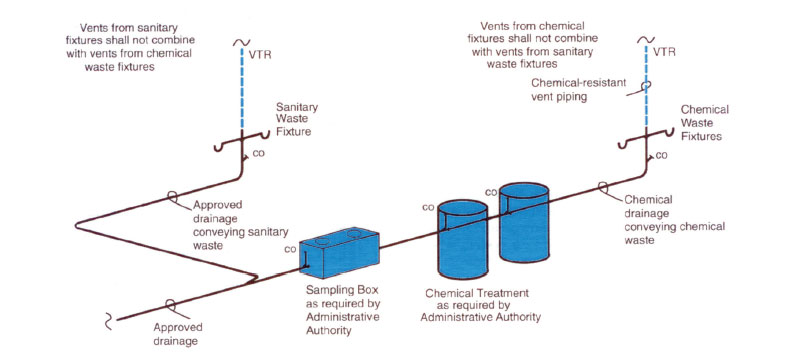

These conditions are usually regulated by both the plumbing official concerned about the drainage piping system and the public works official concerned about the operation of the public sewage treatment plant. The common practice is to intercept, neutralize or provide adequate treatment to liquid wastes on private property before such wastes enter any part of the drainage system or drain to an outside waterway, such as a stream, river, or lake (see Figure 306.1).

PRETREATMENT WITH SAMPLING BOX

Any drainage piping used to convey industrial wastes prior to treatment must be carefully selected and approved. Approved materials include lead, glass, extra-strength vitrified clay, stainless steel and certain types of plastic. Most pipe manufacturers will provide technical data that show acceptable concentrations of chemicals and temperature limits for the various products. Vent piping for a chemical waste system must be of the same or other approved material required for chemical wastes.

Petroleum products must not enter the drainage system. The main concern is the danger of combustion within the drainage piping. Also, a mix of sand and oil can form a solid mass that could cause blockages within the drainage piping system.

Some wastes contain chemical content that may be detrimental to the functioning of the sewage treatment plant. If organic bacteria are killed by chemicals in the wastewater, the sewage treatment plant will be impaired in its ability to function.

Another concern is that chemicals may cause severe corrosion to metal piping or machinery associated with the sewage treatment system. Acid solutions can cause damage to concrete pipe or concrete tanks. In such cases, the AHJ will require an appropriate method of disposal.

306.2 Safe Discharge. Sewage or other waste from a plumbing system that is capable of being deleterious to surface or subsurface waters shall not be discharged into the ground or a waterway unless it has first been rendered safe by some acceptable form of treatment in accordance with the Authority Having Jurisdiction.

From the 2024 UMC Illustrated Training Manual, Chapter 10 – BOILERS AND PRESSURE VESSELS

1008.0 Low-Water Cutoff.

1008.1 General. Hot water boilers and steam boilers shall be installed with a low-water cutoff. A coil-type boiler or a water-tube boiler that requires forced circulation to prevent overheating of the coils or tubes shall be installed with a flowsensing device in the outlet piping in lieu of the low-water cutoff. The low-water cutoff or the flow sensing device shall be installed so as to prevent damage to the boiler and to permit testing of the fuel-supply cutoff without draining the heating system. The low-water cutoff shall shut off the energy source at a water level setpoint that is in accordance with the boiler manufacturer’s instructions.

A low-water cutoff (LWCO) is a mechanical or electronic sensor that monitors the water level in a boiler or boiler system and turns off electrical power to the burner if the water level or pressure falls below a preset, safe level. The boiler needs water to move the heat away from metal surfaces.

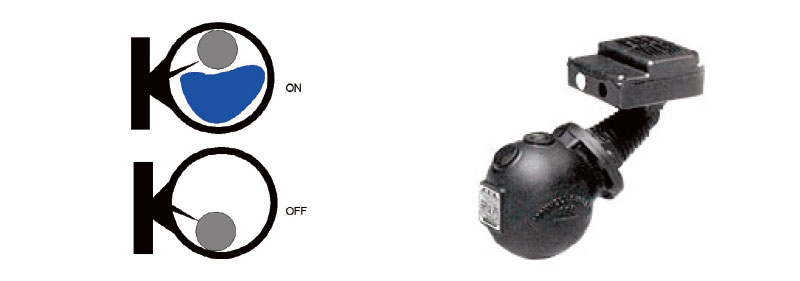

Mechanical-Float LWCO

Original LWCO valve designs used a mechanical float that operated like a light switch using the water level as the actuator (see Figures 1008.1a and 1008.1b). The water level in the LWCO chamber will mimic the water level in the boiler. When the water level drops, the float valve also drops, opening the switch and turning off the burner. It will stay off until the water level raises the float to a safe level and the circuit is closed again.

RIGHT: FIGURE 1008.1B, FLOAT TYPE LWCO (Courtesy of McDonnell & Miller)

Float-operated low-water cutoffs have been around since the 1920s. This type of LWCO is typically mounted in the boiler’s gauge glass tappings.

Mechanical-float LWCOs can get hung up or jammed due to sludge that forms as water is lost from the boiler and mineral debris is left behind. The valve should be cleaned and flushed regularly.

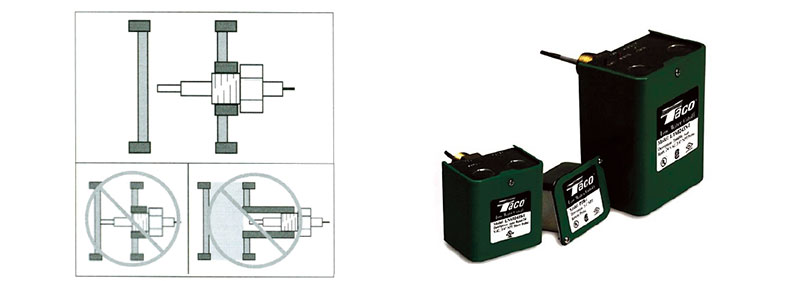

Electronic LWCO

Electronic LWCO controls have generally replaced the mechanical float. The electronic LCWO uses a switch and a sensor, reducing the chances of a mechanical malfunction due to sludge or debris (see Figures 1008.1c and 1008.1d).

RIGHT: FIGURE 1008.1D, ELECTRONIC LWCO (Courtesy of Taco)

Like the mechanical-float-type LWCO, they will interrupt the electrical current to the burner if the water in the system drops below the sensor’s probe. A probe uses the boiler’s water to complete an electrical circuit past an insulator (the center portion of the probe) back to a ground (the threaded portion of the probe). As long as water covers the probe, the circuit is completed to the burner. When water drops off the probe for 10 seconds, the burner circuit is open, preventing the burner from firing.

Some electronic LWCO also provide an additional circuit for a low-water alarm.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: November 14, 2024