October 24, 2024

From the 2024 UPC Illustrated Training Manual, Chapter 4 – PLUMBING FIXTURES AND FIXTURE FITTINGS

422.1 Fixture Count. Plumbing fixtures shall be provided for the type of building occupancy and in the minimum number shown in Table 422.1. The total occupant load and occupancy classification shall be determined in accordance with the building code. Occupancy classification not shown in Table 422.1 shall be considered separately by the Authority Having Jurisdiction.

Before you can use Table 422.1 as it is intended, it is crucial to note the second sentence in this section that states “The total occupant load and occupancy classification shall be determined in accordance with the building code”. You must have that information before you attempt to use Table 422.1. The Authority Having Jurisdiction will determine the occupant load for the building or space.

Table 422.1 is based on research conducted by the American Society of Plumbing Engineers (ASPE) and the Stevens Institute. The research is based on the “Queuing Theory” for plumbing design. This theory provides answers to the following questions:

- How long might a user wait?

- How many people will form in the line?

- How many service equipment items are needed? The theory provides a tool for determining the number of plumbing fixtures for a preferred level of service expressed in:

- Waiting times during peak periods of use.

- Fixture utilization.

- The probability of finding a vacant fixture.

Fixture counts in the past tended to underestimate the needs for small occupancies and to overestimate the needs for larger occupancies. The “Queuing Theory” tends to provide a better analysis of user service distribution to determine the minimum number of fixtures. The revisions correlate with the classifications of building codes along with recommendations from the American Restroom Association and the Journal of Planning Literature, Gender and Family Issues in Planning and Designing Public Restrooms. The revisions also address issues such as potty parity, employee and customer facilities, occupancies with peak usage, and waiting lines for women in various occupancies.

From the 2024 UMC Illustrated Training Manual, Chapter 5 – EXHAUST SYSTEMS

503.0 Motors, Fans, and Filters.

503.1 General. Motors and fans shall be sized to provide the required air movement. Motors in areas that contain flammable vapors or dusts shall be of a type approved for such environments. A manually operated remote control installed at an approved location shall be provided to shut off fans or blowers in flammable vapor or dust systems. Equipment used in operations that generate explosive or flammable vapors, fumes, or dusts shall be interlocked with the ventilation system so that the equipment cannot be operated unless the ventilation fans are in operation. Motors for fans used to convey flammable vapors or dusts shall be located outside the duct or shall be protected with approved shields and dustproofing. Where belts are used, they shall not enter the duct unless the belt and pulley within the duct are enclosed. Motors and fans shall be accessible for servicing and maintenance.

Motors and fans must be sized to provide the air movement needed for efficient operation of the system. Among the factors to be considered are required volume, required velocities, duct and fitting pressure losses and fan characteristics. The code requires that motors in areas containing flammable vapors or dusts be of types approved for such an environment.

A manually operated remote control switch installed in an approved location (one that is well marked and accessible) must be provided to shut down the fans and blowers in flammable vapor or flammable dust-conveying systems.

Any electrical equipment (saws, grinders, buffing wheels, etc.) used in industrial operations that generate explosive or flammable vapors, fumes or dusts must be electrically interlocked with the product-conveying duct system (makeup and exhaust air). This interlock prevents operation of contaminant producing power equipment when the ventilation system is not operating. In this way, a dangerous build-up of vapor or dust may be avoided since they can be ignited by a spark or heat from power equipment. Motors or fans used to convey flammable dust or vapors must be located outside the duct or be protected with an approved shield and dust-proofing method.

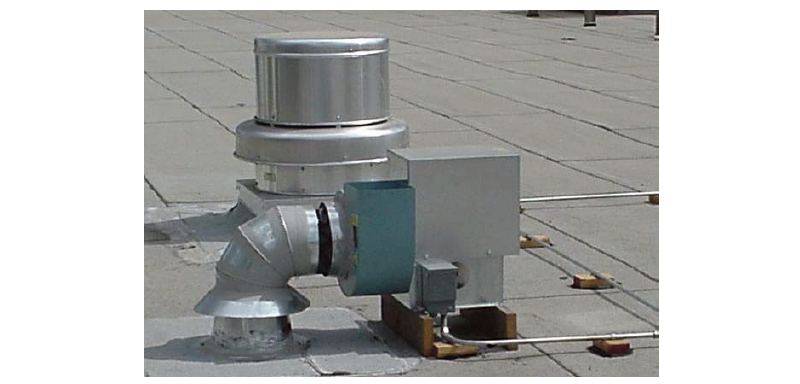

An acceptable design can be a fan within the duct, with the motor located outside and connected via a belt (see Figure 503.1). Such motors and fans must be accessible for servicing and maintenance. This is essential for reliable operation and long system life.

PRODUCT-CONVEYING DUCT

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: October 24, 2024