September 26, 2024

From the 2024 UPC Illustrated Training Manual, Chapter 8 – INDIRECT WASTES

814.2 Condensate Control. Where any equipment or appliance is installed in a space where damage is capable of resulting from condensate overflow, a drain line shall be provided and shall be drained in accordance with Section 814.1. An additional protection method for condensate overflow shall be provided in accordance with one of the following:

(1) A water level detecting device that will shut off the equipment or appliance in the event the primary drain is blocked. Such detecting device shall be in accordance with the manufacturer’s installation instructions.

(2) An additional watertight pan of corrosion-resistant material, with a separate drain line, installed beneath the cooling coil, unit, or the appliance to catch the overflow condensate due to a clogged primary condensate drain.

(3) An additional separate drain line at a level that is higher than the primary drain line connection of the drain pan.

(4) An additional watertight pan of corrosion-resistant material with a water level detection device installed beneath the cooling coil, unit, or the appliance to catch the overflow condensate due to a clogged primary condensate drain and to shut off the equipment.

The additional pan or the additional drain line connection shall be provided with a drainpipe of not less than 3/4 of an inch (20 mm) nominal pipe size, discharging at a point that is readily observed.

When equipment or appliances are installed in a space where damage may result from a blocked primary condensate drain, an overflow or secondary drain must be provided. There are several ways to meet this requirement and the appropriate method is mostly dependent on the design of the equipment or appliance. If the equipment or appliance is equipped with an overflow (secondary) connection, it is to be piped to discharge to a conspicuous location so the public would be alerted that the primary drain is stopped. Approved locations could vary with jurisdictions but would include a point above a showerhead in a bathtub or shower or outdoors above an exterior window. If no additional separate drain outlet is provided, a watertight, corrosion-resistant pan is to be installed under the equipment or appliance to collect the overflow. The pan should be piped similarly to the secondary drain pipe. The pan drain pipe shall be a minimum 3/4 inch, discharging at a point that can be readily observed.

From the 2024 UMC Illustrated Training Manual, Chapter 8 – CHIMNEYS AND VENTS

802.3 Minimum Safe Performance. Venting systems shall be designed and constructed to convey all flue and vent gases to the outdoors. [NFPA 54:12.1]

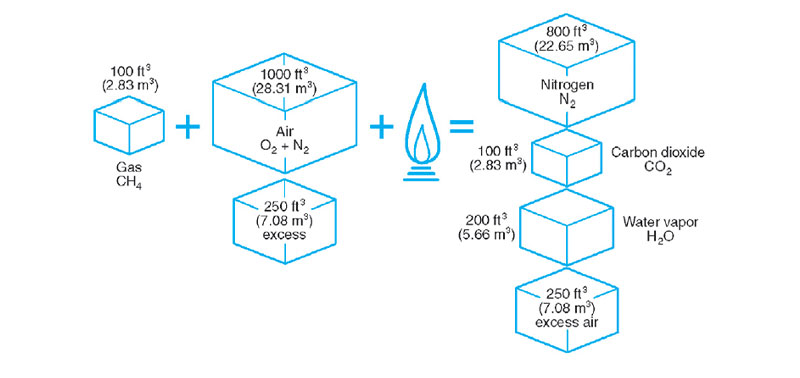

COMBUSTION OF NATURAL GAS

Although gas is a clean-burning fuel, the products of combustion must not be allowed to accumulate inside of a building. (See Figure 802.3 for the products of combustion formed under ideal conditions.) Therefore, venting of most gas utilization equipment is required (see Section 802.2.1 for a list of appliances not requiring venting). A properly installed and maintained venting system will perform the following functions to provide for proper appliance function and the safety of building occupants:

- Convey all of the combustion products to the outside atmosphere.

- Prevent damage to the gas equipment, from water vapor condensation in the flue.

- Prevent overheating of walls, building structure and other combustible materials that are installed with required clearance to the appliance and venting system.

- Provide fast priming of natural draft-venting systems to minimize spillage of combustion products into the building.

The venting system’s job is to channel combustion products out of the building. To do so, the venting system must keep the combustion products as warm as possible in the vent. Heat retention maximizes the draft produced.

High-efficiency condensing appliances have a seasonal efficiency of 90 percent or higher. This reduces vent gas temperatures to a point where the water vapor produced as a product of combustion condenses to liquid water in the appliance or in the vent. These condensing appliances carry a vented appliance category of Category IV. This type of appliance produces much cooler vent gases resulting in water condensing in the vent. Venting must be accomplished with a fan because the vent gases are not hot enough to operate the natural draft vent. Water will condense in the vent and will dissolve some of the gases produced during combustion, which are slightly acidic. The vent materials used with these appliances must be able to resist the acidic condensate.

The advantage of high-efficiency appliances is that they reduce the amount of gas consumed with no loss in output. A mid-efficiency appliance uses one-third less gas than a conventional appliance, and a condensing appliance uses only one-half of the gas of a conventional appliance. The savings of fuel are offset by higher first cost, and the higher maintenance requirements of high-efficiency appliances.

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: October 10, 2024