August 29, 2024

From the 2024 UPC Illustrated Training Manual, Chapter 6 – WATER SUPPLY AND DISTRIBUTION

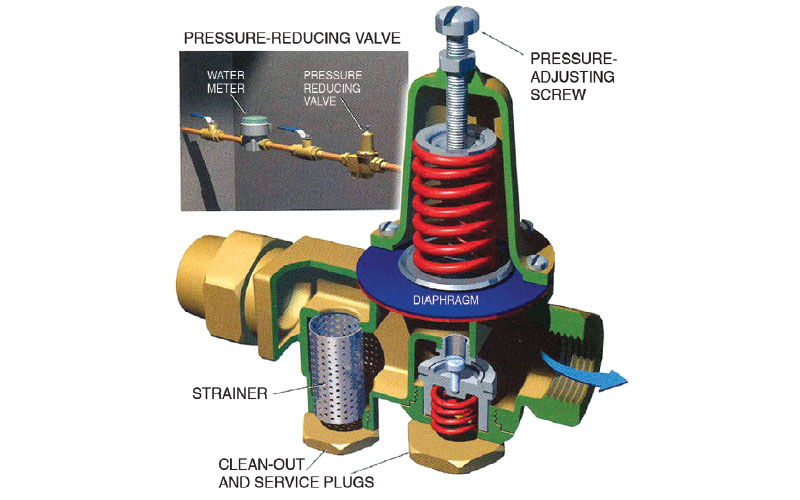

608.2 Excessive Water Pressure. Where static water pressure in the water supply piping exceeds 80 psi (552 kPa), an approved-type pressure regulator preceded by an adequate strainer shall be installed and the static pressure reduced to 80 psi (552 kPa) or less. Pressure regulators for potable water distribution systems shall comply with ASSE 1003 or AWWA C530. Pressure regulator(s) equal to or exceeding 1 1/2 inches (40 mm) shall not require a strainer. Such regulator( s) shall control the pressure to water outlets in the building unless otherwise approved by the Authority Having Jurisdiction. Each such regulator and strainer shall be accessibly located aboveground or in a vault equipped with a properly sized and sloped boresighted drain to daylight, shall be protected from freezing, and shall have the strainer readily accessible for cleaning without removing the regulator or strainer body or disconnecting the supply piping.

Pipe size determinations shall be based on 80 percent of the reduced pressure where using Table 610.4.

An approved expansion tank shall be installed in the cold water distribution piping downstream of each such regulator to prevent pressure exceeding 80 psi from developing due to thermal expansion. Expansion tanks used in potable water systems intended to supply drinking water shall comply with NSF/ANSI/CAN 61. The expansion tank shall be properly sized, securely fastened to the structure, and installed in accordance with the manufacturer’s installation instructions and listing. Systems designed by a licensed plumbing contractor or registered design professionals shall be permitted to use approved pressure relief valves in lieu of expansion tanks provided such relief valves have a maximum pressure relief setting of 100 psi (689 kPa) or less.

A limit of 80 psi (551.6 kPa) is the maximum static pressure of any water supply system. The reason for this is to reduce water hammer, unnecessary use of water, splashing, excessive discharge of pressure relief valves and to protect appliance and fixture valves and mechanisms from pressure that exceeds their design limits. Any installation with pressures above 80 psi will require a pressure regulating valve to limit the pressure to 80 psi or below (see Figure 608.2).

PRESSURE REDUCING VALVE WITH STRAINER

By design, pressure regulating or reducing valves are modulating valves, which have a high level of flow resistance and consequent pressure drop through them even when fully open. Therefore, pipe sizing downstream of the pressure regulator must be based on “worst-case” pressure loss during a maximum demand water flow. Worst-case pressure loss through a listed pressure regulator is presumed to be no greater than 20 percent; therefore, the water system is sized based upon 80 percent of the pressure regulator’s “set” pressure, this being a selected static pressure that is presumed not to exceed 80 psi. Therefore, all pipe size determinations downstream of the regulator must be based on 80 percent of this reduced pressure when using Table 610.4.

For example, a water system has a pressure of 100 psi. A pressure regulator will be installed and set at 80 psi. For sizing purposes using Table 610.4, the maximum pressure would be 64 psi, which is 80 percent of 80 psi.

From the 2024 UMC Illustrated Training Manual, Chapter 13 – FUEL GAS PIPING

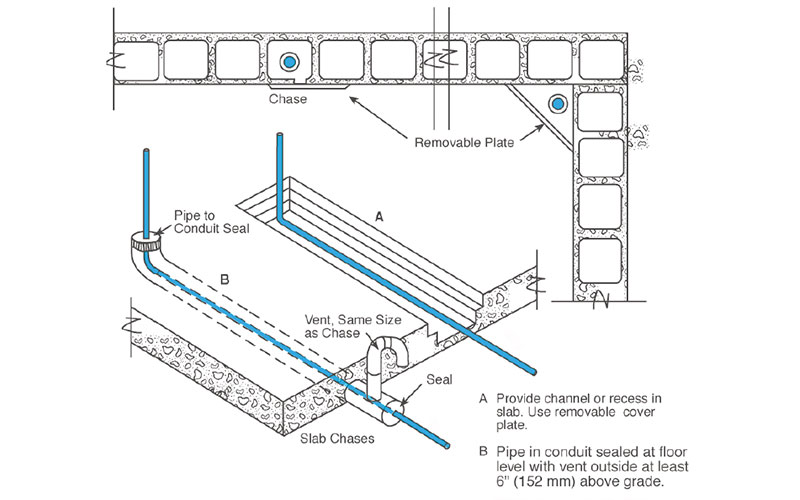

1310.1.6 Piping Underground Beneath Buildings. Where gas piping is installed underground beneath buildings, the piping shall be either of the following:

(1) Encased in an approved conduit designed to withstand the imposed loads and installed in accordance with Section 1310.1.6.1 or Section 1310.1.6.2.

(2) A piping/encasement system listed for installation beneath buildings. [NFPA 54:7.1.6]

Gas leaking from a pipe installed underneath a building can migrate into the building. The code requires that any such pipes be cased and that the annular space between the pipe and the case be vented to the outdoors. Although the resulting installation is perfectly safe, the installation is difficult and the repairs are more so. For these reasons, practicality demands that most pipes run through buildings, rather than under them (see Figure 1310.1.6).

APPROVED PIPING MAY BE INSTALLED IN OTHER LOCATIONS WITH PERMISSION FROM THE AUTHORITY HAVING JURISDICTION

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: October 10, 2024