From the 2024 UPC Illustrated Training Manual, Chapter Chapter 7, SANITARY DRAINAGE

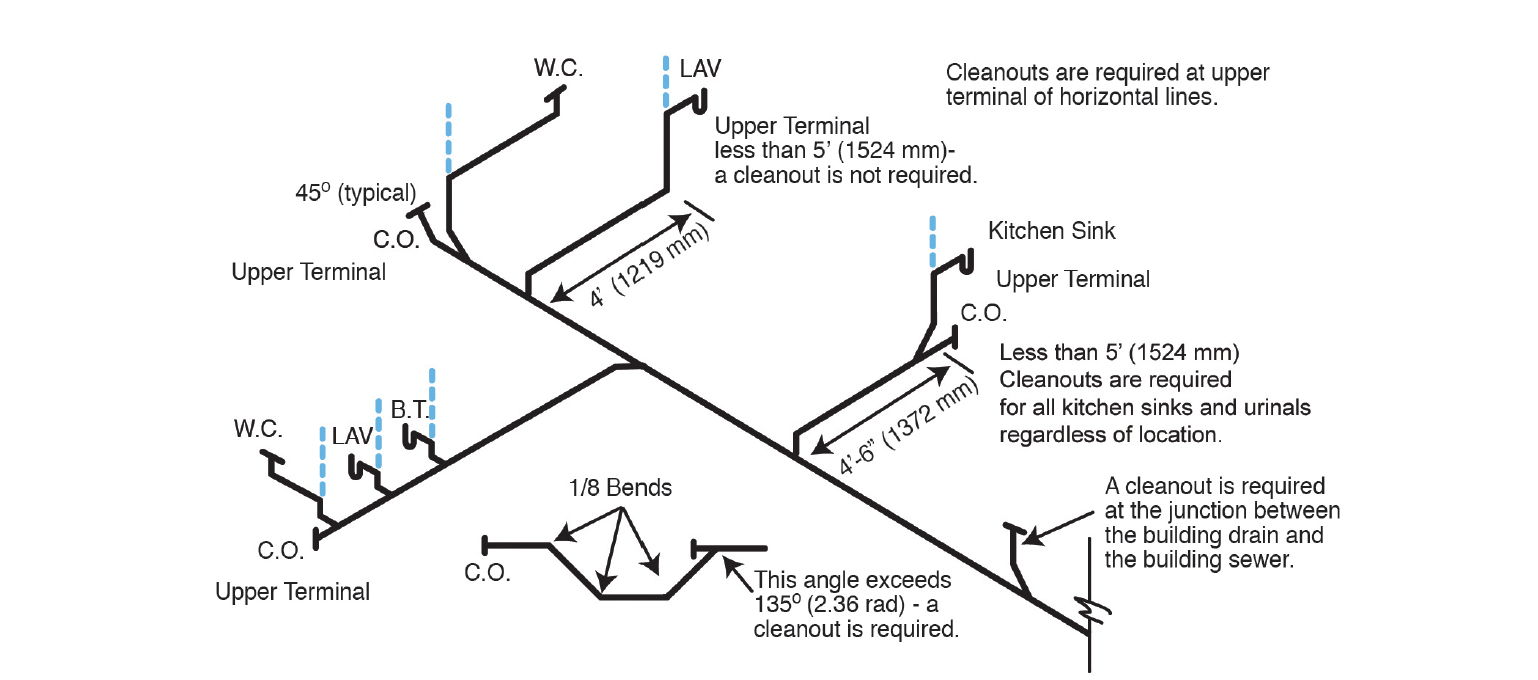

707.4 Location. Each horizontal drainage pipe shall be provided with a cleanout at its upper terminal, and each run of piping, that is more than 100 feet (30 480 mm) in total developed length, shall be provided with a cleanout for each 100 feet (30 480 mm), or fraction thereof, in length of such piping. An additional cleanout shall be provided in a drainage line for each aggregate horizontal change in direction exceeding 135 degrees (2.36 rad). A cleanout shall be installed above the fixture connection fitting, serving each urinal, regardless of the location of the urinal in the building.

Exceptions:

(1) Cleanouts shall be permitted to be omitted on a horizontal drain line less than 5 feet (1524 mm) in length. unless such line is serving sinks or urinals.

(2) Cleanouts shall be permitted to be omitted on a horizontal drainage pipe installed on a slope of 72 degrees (1.26 rad) or less from the vertical angle (one-fifth bend).

(3) Excepting the building drain, its horizontal branches, kitchen sinks, and urinals, a cleanout shall not be required on a pipe or piping that is above the floor level of the lowest floor of the building.

(4) An approved type of two-way cleanout fitting, installed inside the building wall near the connection between the building drain and the building sewer or installed outside of a building at the lower end of a building drain and extended to grade, shall be permitted to be substituted for an upper terminal cleanout.

Cleanouts are required for horizontal drainage piping (see Figure 707.4). For long runs of piping, a cleanout is required every 100 feet. This measurement is taken from the highest end of the horizontal drainage piping to the point of connection with the building sewer. Installing a cleanout above the fixture connection fitting serving each urinal will provide access for mechanically cleaning the drain line without having to remove the urinal from the wall.

Of course, there are exceptions to this requirement:

- Except for sinks and urinals, a horizontal drain line less than five feet does not require a cleanout.

- A direct projection from the building drain in a vertical direction does not require a cleanout. The angle of less than 72 degrees from the vertical does not meet the definition of “vertical” until it reaches a 45-degree angle, but this is referring to pipe with a significant slope from the drain.

- This is a significant exception. A cleanout is only required on the building drain as it is defined in Chapter 2: Building Drain – “That part of lowest piping of a drainage system which receives the discharge from soil, waste and other drainage pipes inside the walls of the building and conveys it to the building sewer beginning two feet outside the building wall.” The building drain and its horizontal branches, along with urinals and kitchen sinks regardless of their location in the building, are required to have cleanouts. All other piping above the first floor of the building is not required to have a cleanout.

- A two-way cleanout at the transition of the building drain and sewer can substitute for an upper terminal cleanout for the building drain. If the building drain is more than 100 feet in developed length, then additional cleanouts will be required.

CLEANOUT REQUIREMENTS

From the 2024 UMC Illustrated Training Manual, Chapter Chapter 5, EXHAUST SYSTEMS

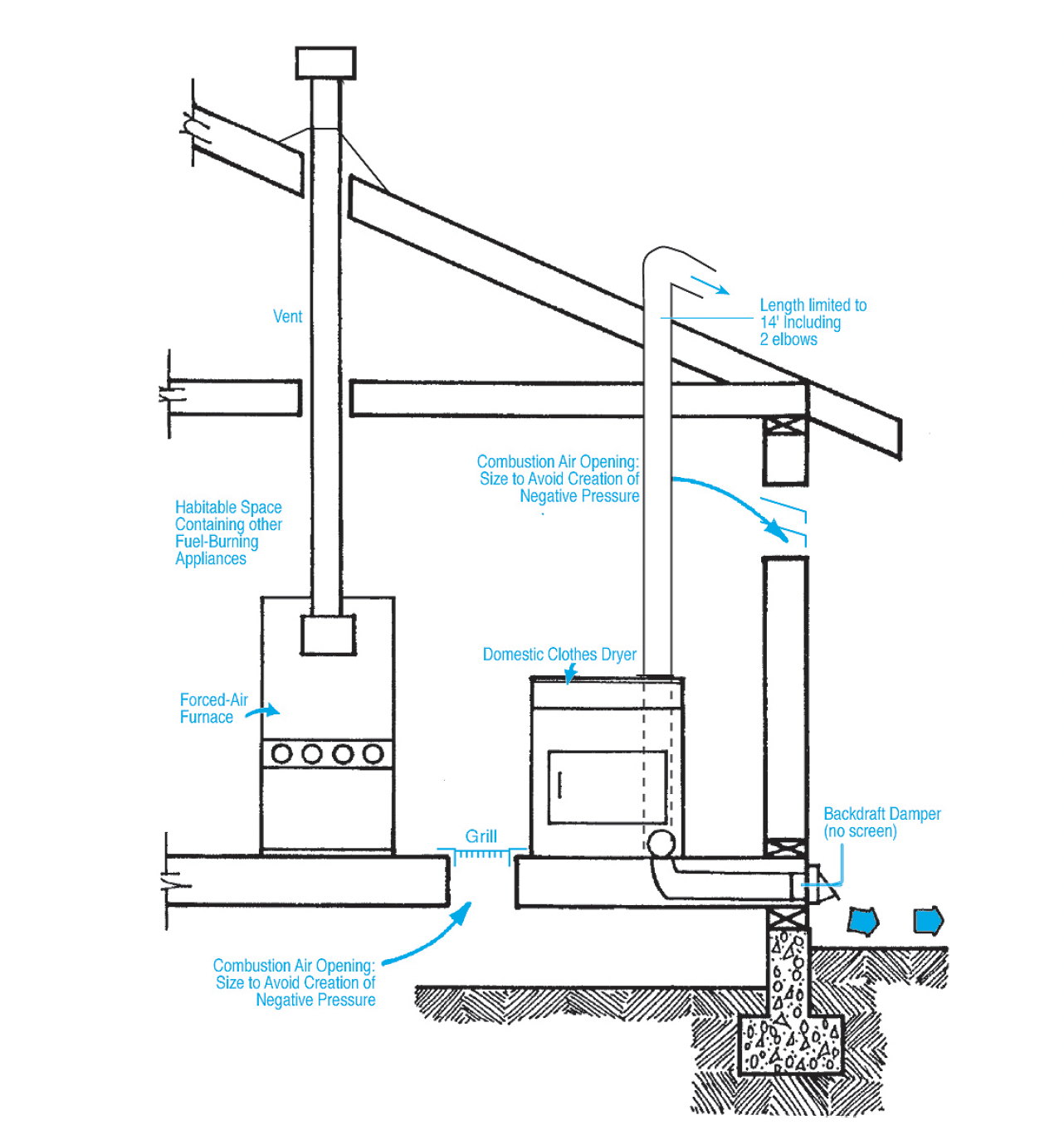

504.4.2 Domestic Clothes Dryers. Where a compartment or space for a Type 1 clothes dryer is provided, not less than a 4 inch diameter (102 mm) exhaust duct of approved material shall be installed in accordance with Section 504.0.

Type 1 clothes dryer exhaust ducts shall be of rigid metal and shall have smooth interior surfaces. The diameter shall be not less than 4 inches nominal (100 mm), and the thickness shall be not less than 0.016 of an inch (0.406 mm).

Designated dryer spaces shall be provided with a 4-inch moisture duct system that is capable of being connected to an owner-provided dryer at a future point in time. This will limit the possibility of noncomplying duct systems being installed by well-meaning but uninformed installers that may violate the provisions of this code and the installation instructions of the appliance.

The operation of Type 1 clothes dryer exhausting to the outside will cause makeup air to eventually come from the outside. Normal building infiltration may not be enough to meet the demand of a dryer, especially if the dryer is located in a closet and operating behind a closed door. The building code of the jurisdiction defines the minimum size of a room. Rooms smaller than the minimum room dimensions may be considered a closet. These smaller spaces require 100 square inches of makeup air as required in Section 504.4.1(1). However, per Section 403.7, Exhaust Ventilation, “Exhaust makeup air shall be permitted to be any combination of outdoor air, recirculated air and transfer air.”

It may seem like a waste of energy to allow nonconditioned air to be introduced into the building. Needs of an appliance to operate in a safe manner and removal of environmental air contaminants should override the desire to keep the house “leakproof” for energy use concerns (see Figure 504.4.2).

Dryer vent temperatures commonly operate at a temperature exceeding the normal operating temperature of a downflow domestic range vent. See Section 603.11 if ducting must be installed below slabs. Note that ground temperatures will greatly increase condensation within the dryer (moisture) exhaust duct.

CLOTHES DRYER AND FORCED-AIR FURNACE

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: May 30, 2024