May 9, 2024

From the 2024 UPC Illustrated Training Manual, Chapter Chapter 7, SANITARY DRAINAGE

710.10 Sump and Receiving Tank Covers and Vents. Sumps and receiving tanks shall be provided with substantial covers having a bolt-and-gasket-type manhole or equivalent opening to permit access for inspection, repairs, and cleaning. The top shall be provided with a vent pipe that shall extend separately through the roof or, where permitted, be combined with other vent pipes. Such vent shall be large enough to maintain atmospheric pressure within the sump under normal operating conditions and, in no case, shall be less in size than that required by Table 703.2 for the number and type of fixtures discharging into the sump, nor less than 11⁄2 inches (40 mm) in diameter. Where the preceding requirements are met and the vent, after leaving the sump, is combined with vents from fixtures discharging into the sump, the size of the combined vent need not exceed that required for the total number of fixtures discharging into the sump. No vent from an air-operating sewage ejector shall combine with other vents.

The statement that the vent from the sump, when combined with the fixture vents from the fixtures draining into the sump, need not exceed the required vent for the total number of fixtures discharging into the sump can be confusing. What is stated here is that the size of the combined vent, i.e. the common vent serving the sump and fixtures discharging into the sump, needs to be sized only according to Table 703.2 for the number and type of fixtures discharging into the sump and does not need to increase when adding the sump vent.

From the 2024 UMC Illustrated Training Manual, Chapter Chapter 5, EXHAUST SYSTEMS

510.3 Openings. Openings shall be provided at the sides or at the top of the duct, whichever is more accessible, and at changes of direction. Openings shall be protected by approved access constructed and installed in accordance with the requirements of Section 510.3.7. [NFPA 96:7.3.1, 7.3.2]

Exception: Openings shall not be required in portions of the duct that are accessible from the duct entry or discharge. [NFPA 96:7.3.3]

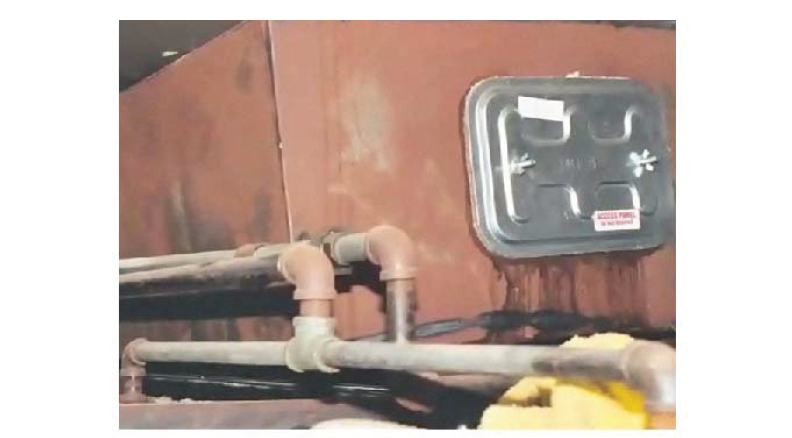

Grease duct systems cannot have openings except those that are necessary for the proper maintenance of the system. A portion of a duct system that is inaccessible from the duct entry at the hood or from the discharge at the fan must be provided with cleanout openings. The entire interior of the duct system must be accessible for cleaning. Cleanout openings must be equipped with tight-fitting doors constructed of steel at least as thick as that required for the duct system. The doors must be equipped with a substantial latching method that is strong enough to hold the doors tightly closed and designed so the doors can be opened without the use of tools. These doors must also be able to resist leakage due to cleaning agents and residual grease in the duct system. A greater amount of grease will naturally collect at the bottom of a horizontal duct, making it more susceptible to leakage. Openings in the bottom of the duct make cleaning of the duct system more problematic, as the cleaning agents will drain out of the access opening that is being worked through. See Figure 510.3.

EXAMPLE OF OPENING IN A DUCT

(This is not to be considered the official position of IAPMO, nor is it an official interpretation of the Codes.)

IAPMO

IAPMO develops and publishes the Uniform Plumbing Code®,the most widely recognized code of practice used by the plumbing industry worldwide; Uniform Mechanical Code®; Uniform Swimming Pool, Spa and Hot Tub Code®; and Uniform Solar Energy, Hydronics and Geothermal Code™ — the only plumbing, mechanical, solar energy and swimming pool codes designated by ANSI as American National Standards — and the Water Efficiency Standard (WE-Stand)™. IAPMO works with government, contractors, labor force, and manufacturers to produce product standards, technical manuals, personnel certification/educational programs and additional resources in order to meet the ever-evolving demands of the industry in protecting public health and safety.

Last modified: May 23, 2024